This article discusses the excellent dust removal efficiency of baghouse dust collectors in waste incineration power plants, achieving over 99.8% efficiency and even reaching 99.99%. However, many issues arise during actual operation and management. Therefore, this article analyzes the problems encountered with baghouse dust collectors in waste incineration power plants and provides corresponding solutions.

I. Common Issues

A. Excessive Resistance During Operation

It is normal for resistance to increase in baghouse dust collectors during operation. If the resistance is moderately high, operators often overlook it. In reality, this increase in resistance raises power consumption and threatens the lifespan of the filter bags. Prolonged operation under these conditions shortens the bag lifespan and endangers the air supply equipment and system.

Severe resistance can lead to bag rupture, preventing the dust collection system from functioning properly. This, in turn, raises operational costs and reduces economic benefits. Common causes of high resistance include:

- High design filter velocity.

- Inadequate selection of filter materials.

- Insufficient handling air volume.

- Increased output due to technical modifications.

Although baghouse dust collectors achieve high dust removal efficiency, their high resistance and maintenance costs have limited their widespread use in waste incineration power plants.

B. Short Lifespan of Filter Bags

The lifespan of filter bags is often short, necessitating frequent replacements, which negatively impacts the economic benefits of waste incineration power generation. Some filter bags can last up to 30,000 hours, while others last only 8,000 hours or even less. Factors contributing to short filter bag lifespans include:

- Mismatched filter material quality with operational requirements.

- Excessively high filter velocity.

C. Difficulty in Cleaning Dust Due to Caking

Dust caking on the surface of filter bags is a frequent issue in waste incineration power plants. This problem arises from improper control of flue gas temperature and the unique composition of flue gas after incineration.

D. Mechanical Failures in Ash Conveying Equipment

The baghouse dust collection system includes bucket elevators and screw conveyors, both of which frequently experience ash blockage.

II. Cause Analysis

A. Low Utilization of Filter Surface Area

Only a small amount of fly ash is carried away by the flue gas passing through the baghouse. Most of the fly ash settles in the lower part of the filter bags, leading to insufficient utilization of the actual filter surface area. This results in significant wear on the bags.

B. Insufficient Automation Control

The automation control system is often inadequate. Temperature sensors may have poor sensitivity, causing discrepancies between the displayed temperature and the actual flue gas temperature. This leads to confusion among operators.

III. Solutions

A. Optimizing Cleaning Methods

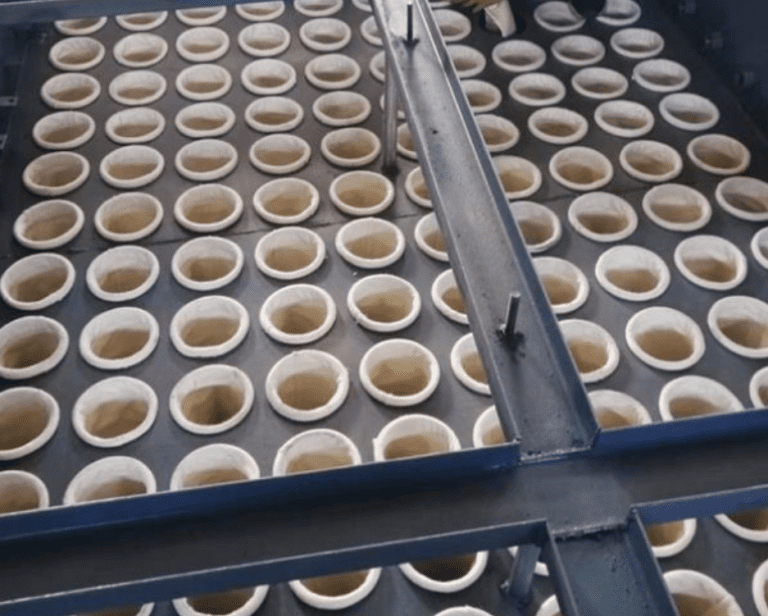

Common cleaning methods for baghouse dust collectors include reverse air, vibration, and pulse cleaning. A segmented chamber design is recommended for easy maintenance without affecting the operation of the incinerator.

B. Selecting Appropriate Filter Materials

Selecting filter materials based on flue gas characteristics is crucial. The choice should consider factors like temperature, humidity, corrosiveness, and dust concentration.

C. Monitoring Flue Gas Acid Dew Point

When the flue gas temperature drops below a certain level, acidic substances may corrode equipment and create a sticky dust layer on the filters. Implementing protective measures, such as heating the ash hopper, can mitigate this issue.

D. Maintaining Ash Conveying Systems

Regular checks on ash moisture levels are essential for screw conveyors and bucket elevators. Increasing the speed of the conveyors can also help reduce blockage issues.

E. Improving Automation Control Systems

Implementing comprehensive monitoring, including remote and manual checks, can enhance automation control.

Conclusion

By analyzing the issues and solutions related to baghouse dust collectors in waste incineration power plants, we see that proper selection and optimization of the dust collection system are crucial for improving economic benefits and environmental protection. If you have any questions or needs regarding baghouse dust collectors or related technologies, please feel free to contact us. We are dedicated to providing excellent service.