What is a Belt Conveyor?

A belt conveyor is a system designed to transport physical items such as materials, goods, and even people from one point to another. Unlike other conveying methods that use chains, spirals, or hydraulics, belt conveyors rely on a continuous belt to move items efficiently.

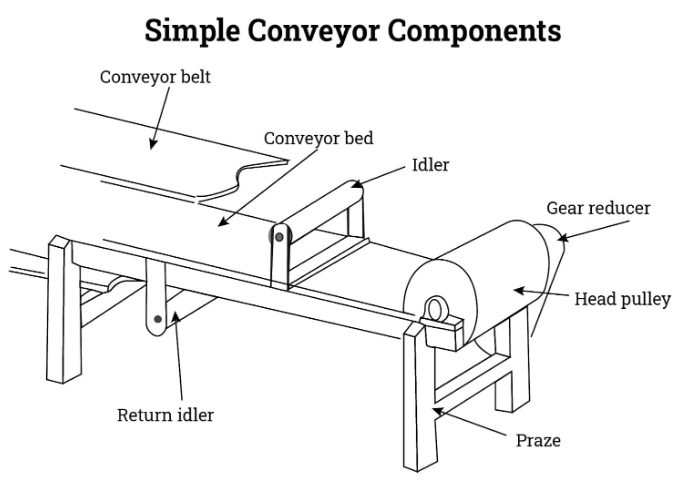

Components of belt conveyors

A standard belt conveyor system has a head pulley, tail pulley, idler rollers, belt, and frame.

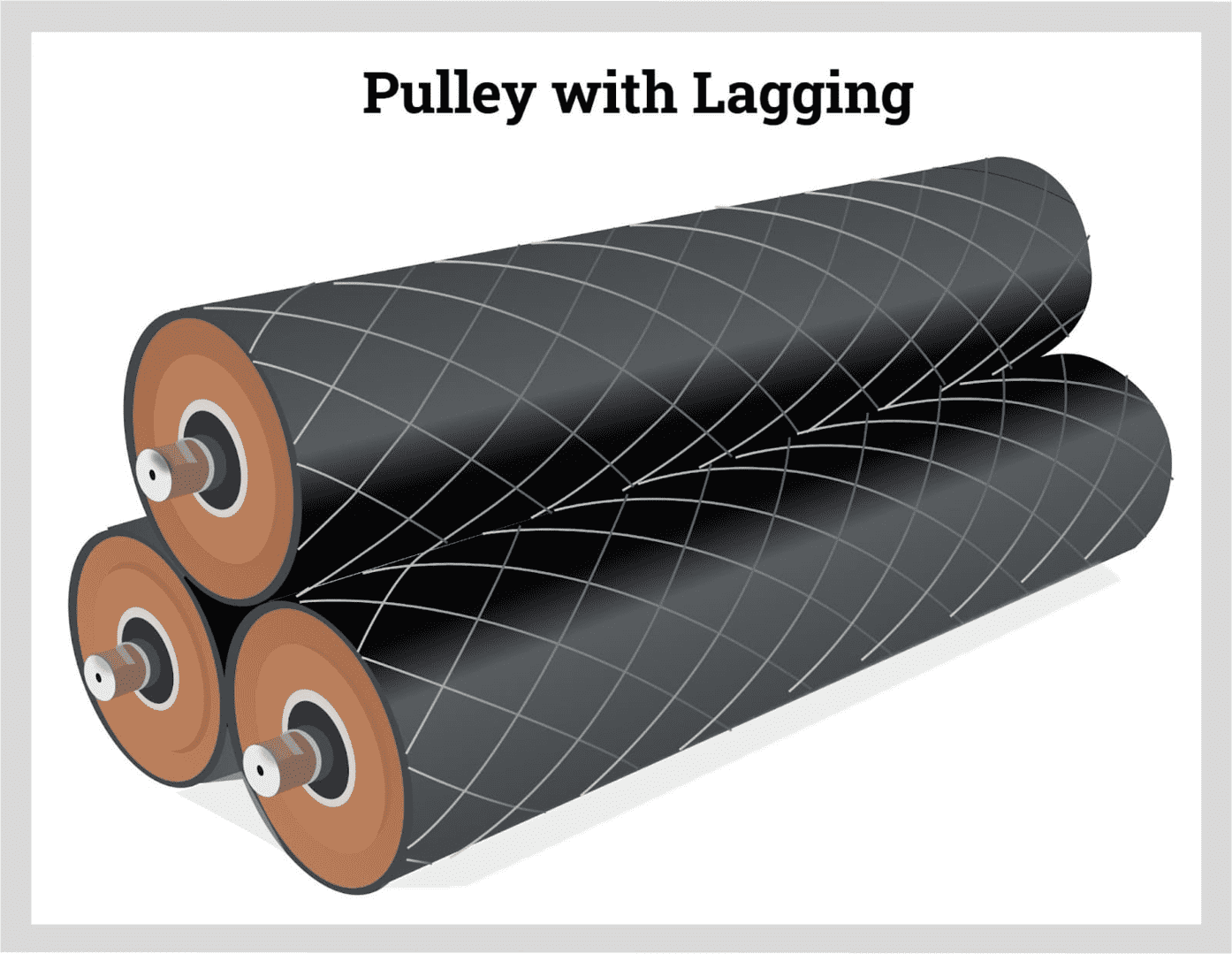

Head Pulley

The head pulley connects directly to the actuator and electric motor, driving the conveyor and generating the necessary pulling force. Located at the discharge end, it efficiently offloads materials. To enhance traction, the head pulley often features a rough jacket, known as a legging, covering its outer surface. Typically, the head pulley boasts the largest diameter among all pulleys in the system. While some systems may include multiple drive pulleys, you will usually identify the one at the discharge end as the head pulley.

Return or Tail Pulley

The return or tail pulleys are positioned at the loading ends of the belt conveyors.Often, it features a wing shape that facilitates cleaning by allowing material to fall away to the support members. In simple setups, the tail pulley mounts on guides, which adjust the belt’s tension. Conversely, in more complex systems, a separate roller known as the take-up roller manages this tension effectively.

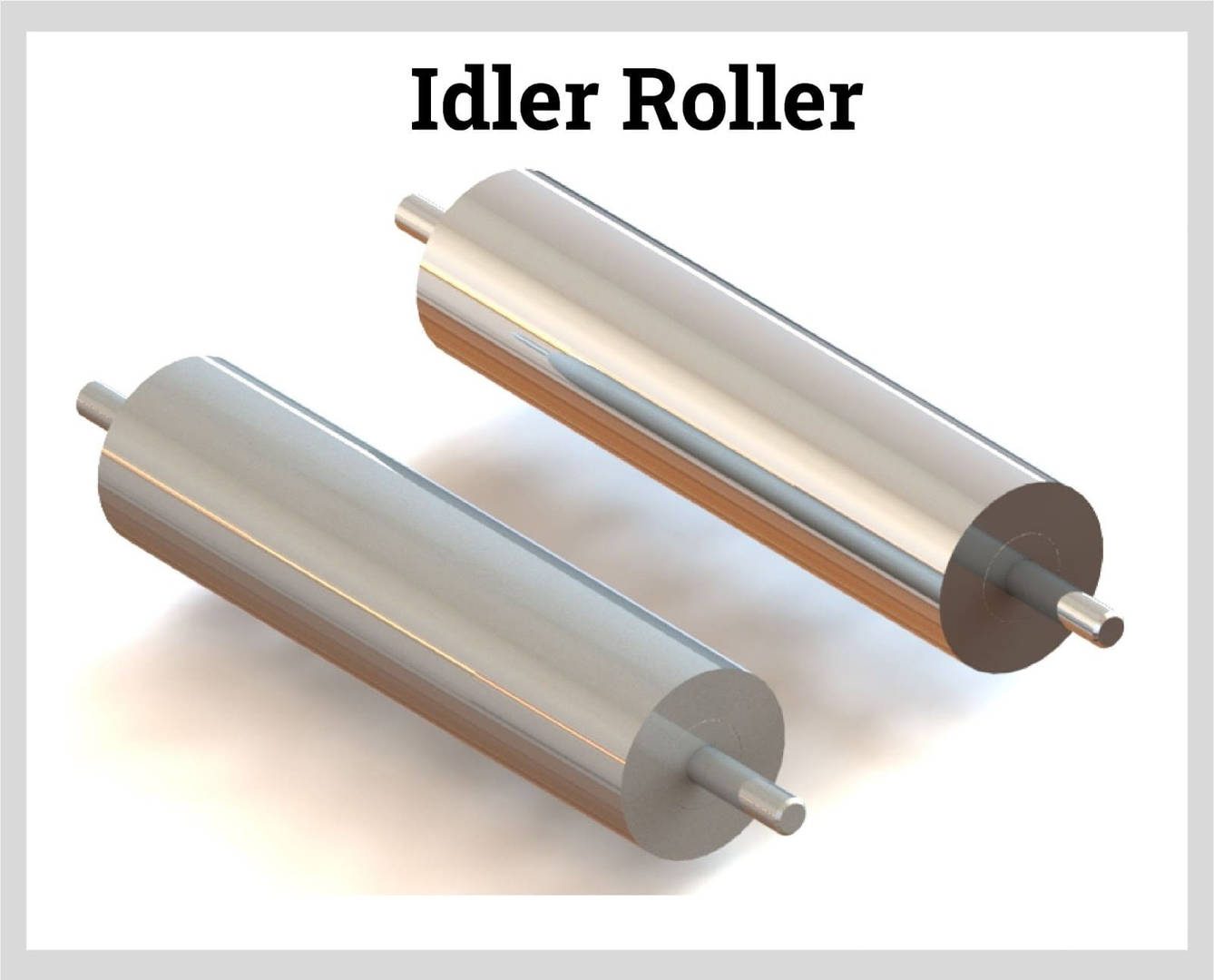

Idler Roller

Idler rollers run along the length of the belt, providing crucial support for both the belt and its load. They play a vital role in preventing sagging, ensuring proper alignment, and helping to clean up carryback—material that tends to stick to the belt. Whether they perform all these functions or just one, idler rollers consistently deliver essential support for the belt’s operation.

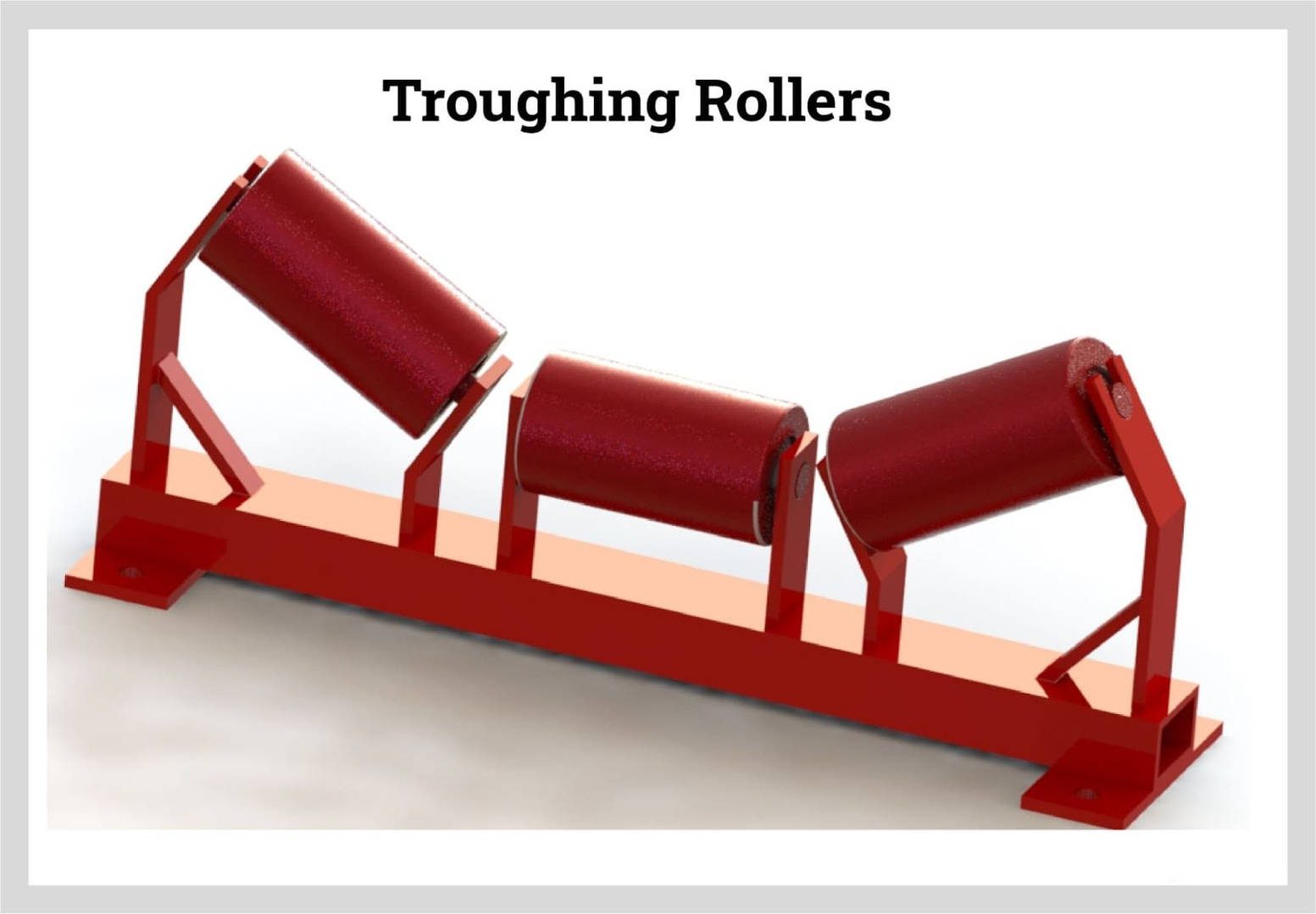

Troughing Idlers

Troughing idlers feature three rollers arranged to form a “trough” shape for the belt. These idlers sit on the side that carries the load. Specifically, the center idler stays fixed, while the two end idlers can adjust to vary the angle and depth of the trough. As a result, this adjustment enhances the conveyor’s efficiency in handling materials.

Benefits of Using Conveyor Belt Systems

Conveyor belt systems act as essential mechanical devices that provide numerous benefits. First, they offer affordability, making them a cost-effective choice for many businesses. Additionally, their ease of use simplifies operations, allowing employees to handle materials efficiently. Moreover, these systems demonstrate versatility by effectively managing a wide range of items, from small objects to large industrial products. Consequently, businesses can streamline their material handling processes and improve overall productivity.

Here are some key benefits:

- Large transmission flow rate

- Very low energy requirements

- Low investment and service costs

- Stable and trouble-free transportation of products

- Easy operation

- Reduced manpower and increased productivity

- Continuous operation

- By integrating a belt conveyor system, businesses can streamline operations and enhance efficiency in material handling.