In today’s rapidly advancing technological landscape, the pharmaceutical industry encounters unique challenges and opportunities. People demand better health and expect higher quality drugs. Additionally, stricter environmental regulations require the industry to prioritize environmental protection during production. Therefore, cartridge dust collectors have emerged as essential green guardians in this sector. Their efficiency and eco-friendliness make them crucial for meeting industry needs.

Basic Principles and Features of Cartridge Dust Collectors

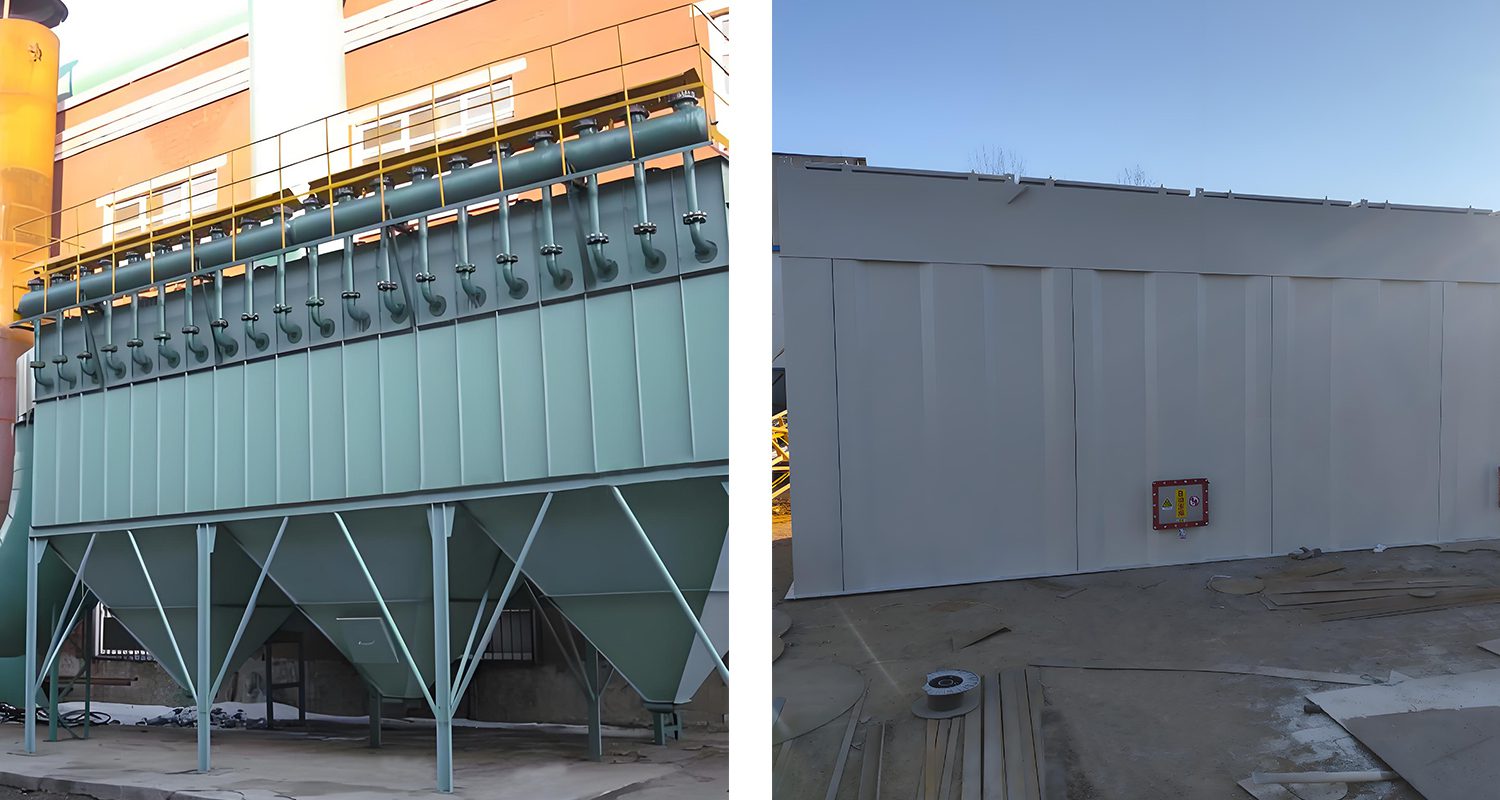

A cartridge dust collector is an advanced dust removal device. It works by filtering dust particles from the air through cartridges. This process purifies the air. The main features include:

High Dust Removal Efficiency: These collectors use advanced filtering materials. They efficiently capture fine dust particles from the air, ensuring a clean production environment.

Energy Saving and Eco-Friendliness: Cartridge dust collectors consume low energy during operation. They can also recover some dust resources for reuse, aligning with modern environmental ideals.

Easy Maintenance: Their well-designed structure makes them easy to disassemble and clean. This feature reduces maintenance costs and enhances reliability and lifespan.

Applications of Cartridge Dust Collector in the Pharmaceutical Industry

Cartridge dust collectors are widely used in the pharmaceutical industry. They cover various processes, such as active pharmaceutical ingredient (API) production, solid dosage form production, and liquid dosage form production. Here are some specific examples:

API Production: This process generates a large amount of dust and harmful gases. Cartridge dust collectors capture these pollutants effectively. They prevent harm to the production environment and protect employee health. Additionally, they recover valuable dust resources, improving raw material utilization.

Solid Dosage Form Production: In the production of solid dosage forms like tablets and capsules, cartridge dust collectors are installed on production lines. They effectively capture generated dust, ensuring a clean production environment and maintaining product quality.

Liquid Dosage Form Production: Although liquid dosage forms produce less dust, some operations, like mixing and filling, may still generate small amounts. Cartridge dust collectors play a crucial role in maintaining cleanliness and ensuring employee health in these processes.

Development Trends and Challenges of Cartridge Dust Collector in the Pharmaceutical Industry

As the pharmaceutical industry evolves, cartridge dust collectors will display several trends:

Intelligent Development: With advancements in IoT and big data, these collectors will become smarter. They will use remote monitoring and data analysis to improve operational efficiency and reliability.

Increased Efficiency and Energy Savings: Future cartridge dust collectors will focus more on efficiency and energy savings. They will use advanced filtering materials and optimize their designs to reduce energy consumption and operational costs.

Environmental Protection and Resource Recovery: These collectors will emphasize environmental protection and resource recovery. They will recycle dust resources, helping conserve resources and protect the environment.

However, the application of cartridge dust collectors also faces challenges. The diversity of dust characteristics and the complexity of production environments require continuous research and development. We must improve technologies to meet the industry’s evolving needs.

Importance of Cartridge Dust Collector in the Pharmaceutical Industry

The use of cartridge dust collectors improves the cleanliness of the production environment and enhances product quality. They also promote sustainable development in the pharmaceutical industry. Their significance includes:

Protecting Employee Health: By capturing dust and harmful gases, these collectors prevent health hazards for employees. They create a safe and healthy working environment.

Improving Product Quality: By ensuring cleanliness in the production environment, cartridge dust collectors enhance product quality and stability. This support is crucial for the industry's development.

Promoting Environmental Protection: Through dust recovery and reuse, these collectors contribute to resource conservation and environmental protection. They play an important role in the sustainable development of the pharmaceutical industry.

Conclusion

Cartridge dust collectors serve as green guardians in the pharmaceutical industry. They provide essential support for development. Their efficiency and environmental benefits are crucial. In the future, as technology advances and awareness of environmental issues increases, these collectors will play an even larger role in the industry. Darko is committed to advancing and innovating cartridge dust collector technology. We aim to contribute to the sustainable development of the pharmaceutical sector. If you have any questions about our dust collectors or services, please feel free to contact us. We look forward to working with you.