Overview

The NE/NSE Plate Chain Bucket Elevator serves as essential equipment for the vertical conveying of granular materials. This elevator is designed to efficiently transport materials in various industrial settings.

NE Series vs. NSE Series

The NE series primarily conveys larger particle-sized materials with high abrasiveness. The NSE series mainly conveys larger particle-sized materials and powders with high abrasiveness. Both series suit operating environments with temperatures from -20°C to +45°C. The conveyed materials should not exceed a temperature of 250°C.

Key Differences

The main difference between the NE and NSE bucket elevators is the chain speed. The NSE series operates with a chain speed that is twice as fast as that of the NE series. This increased speed allows for more efficient material handling in certain applications.

Specifications

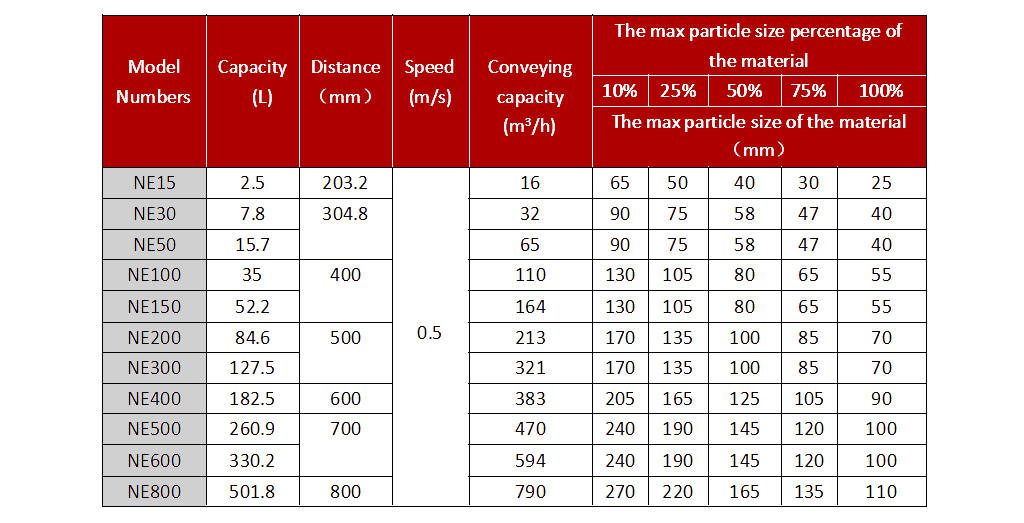

The NE/NSE Plate Chain Bucket Elevator encompasses a series of products. The NE series includes a total of 11 specifications, featuring a maximum conveying capacity of 790 m³/h and a maximum lifting height of up to 45 m.

The NSE series has a total of 8 specifications, with a maximum conveying capacity of 830m3/h and a maximum lifting height of 50m.

Applications and Benefits

These bucket elevators are versatile, suitable for various industries, including:

- Cement Industry: Efficiently transferring clinker and other materials.

- Mining: Handling heavy ores and minerals.

- Food Processing: Safely transporting granulated and powdered food products.

The NE/NSE elevators ensure minimal material degradation during transport, preserving the quality of the conveyed substances. Their durable construction minimizes maintenance needs, leading to lower operational costs over time.

Conclusion

In summary, the NE/NSE Plate Chain Bucket Elevator offers a reliable solution for vertical conveying of granular materials. By understanding the differences between the NE and NSE series, businesses can select the most suitable option for their specific requirements. With their robust design, high capacities, and efficient operation, these bucket elevators play a vital role in enhancing productivity across various industries.If you have any questions or need assistance, please contact us.