Belt conveyor roller are important components of belt conveyors, there are many types and large quantities. It accounts for 35% of the total cost of a belt conveyor and produces more than 70% of the resistance, so the quality of the roller is particularly important.

Conveyor rollers consist of several parts: housing, shaft, bearing, seals, and snaps. Our mechanical conveyor rollers feature a unique structure, reliable components, precise assembly, high capacity, and long service life.

The primary function of the rollers is to support the weight of the conveyor belt and its load. They must be flexible and dependable. Rollers help reduce belt running resistance and maintain the verticality of the belt, ensuring smooth operation. Reducing friction between the conveyor belt and the rollers is vital for extending the belt's lifespan, which constitutes over 25% of the total conveyor cost.

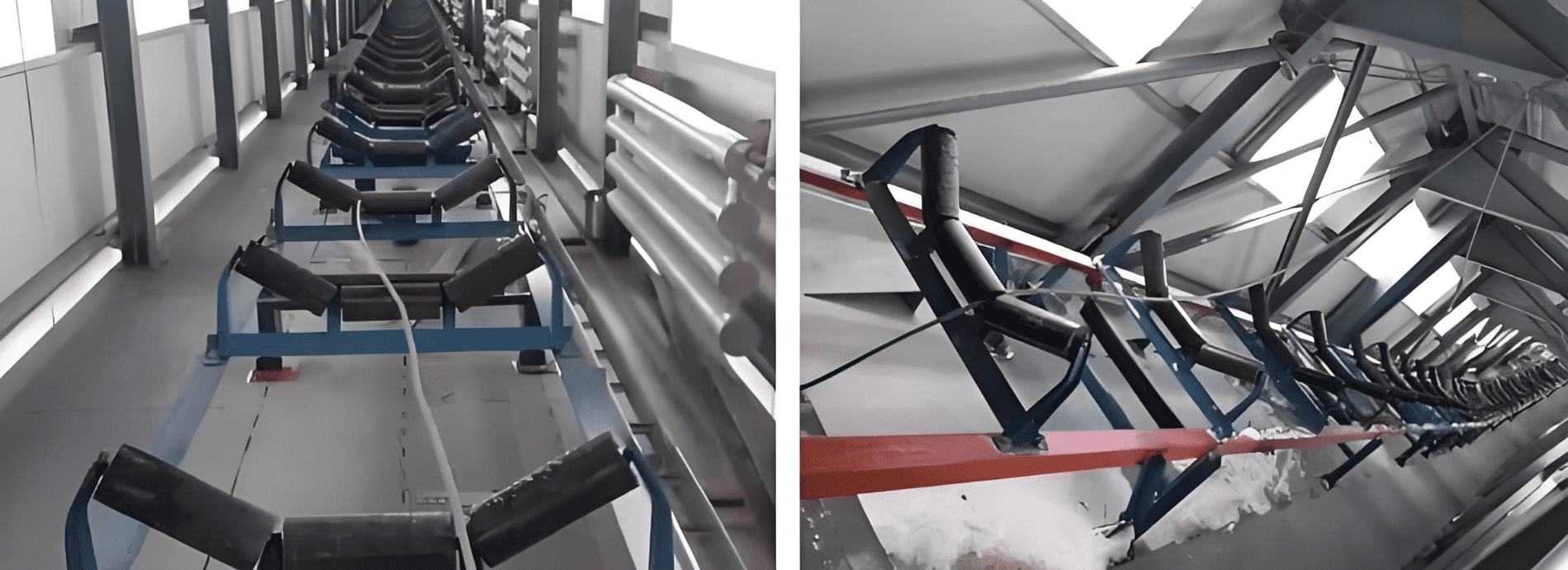

Three Roll Trough

This is a standard idler design used in most heavy-duty conveyor applications. The rollers can be made of steel and are often coated with multiple layers of specific paint, rubber, or other anti-corrosive materials.

The rollers may be in steel, covered with several layers of a particular specifi cation of paint, or covered in rubber or in other anti corrosive materials.

Roller Series and Applications

These rollers are particularly suited for conveyors operating in challenging conditions, where working loads are high and large lump sizes are conveyed. Despite these demands, they require minimal maintenance. Typical applications include mines, cement works, coal-fired power plants, and dock installations.

The roller sealing system effectively addresses environmental challenges such as dust, dirt, water, and extreme temperatures. Standard greased components function well within a temperature range of -20°C to +100°C. For applications outside this range, special grease, bearings, and seals can be used.