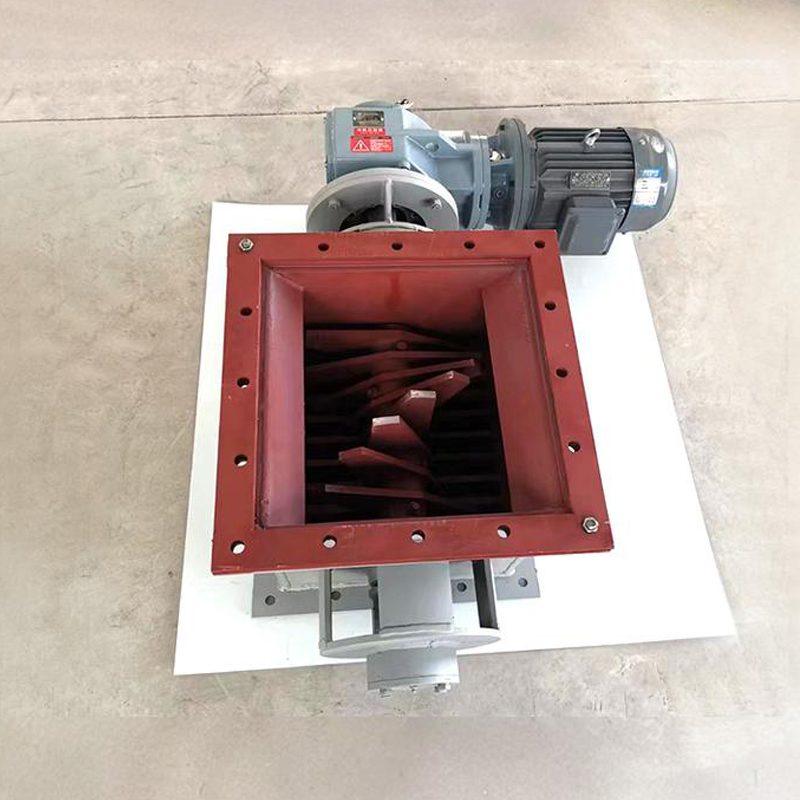

What is the purpose of a double flap valve?

The double flap valve is an ash discharge and airlock valve widely used in plants such as building materials, metallurgy, petrochemicals, and power generation. It serves as an airlock and ash discharge device for various dust collection equipment and ash hoppers, as well as for mills, dryers, silos, and closed conveying systems.

Darko's double flap valve has become an efficient, reliable, and versatile solution for a wide range of material handling applications both domestically and internationally.

♦Alternating double flap mechanism:

Utilizes two flaps that open and close alternately, ensuring continuous material flow while maintaining effective air sealing.

♦Sealing Performance:

Designed to prevent air leakage above and below the valve during operation, thus maintaining system pressure and preventing contamination.

♦Continuous Discharge:

Specifically designed for uninterrupted material flow, aiding in the stable and controllable discharge of bulk materials.

♦Wear-Resistant Options:

For abrasive materials, the valve can be equipped with Hardox linings in the valve plates and body, significantly enhancing its wear resistance.

♦Versatility in Material Handling:

Capable of handling various bulk materials under both positive and negative pressure conditions, including solids, granules, powders, and dense materials.

♦Low Maintenance:

The robust design minimizes wear and requires less maintenance compared to other types of valves.

♦Compatible with Various Pressure Conditions:

Effectively operates under both positive and negative pressure conditions, suitable for different setups.

♦Safety and Compliance:

Designed to meet relevant industry safety standards, ensuring reliable and safe operation in various manufacturing environments.

♦Customizable Design Options:

Materials of construction (MOC) can be tailored to specific application needs, enhancing compatibility with different types of bulk materials.

♦Variety of Actuator Configurations:

Offers different actuator options, including pneumatic, electric, and hydraulic, to meet various operational requirements and seamlessly integrate with existing systems.

Structure characteristic

The double flap airlock valve is a device that utilizes the weight of materials for automatic ash discharge, widely used in domains such as metallurgy, chemical engineering, power generation, light manufacturing, building materials, construction, mining, cement, grain, and food.

Its main structural features include:

- Welded Steel Plate Structure: Made with a welded steel plate structure, it is compact and operates smoothly and reliably.

- Counterweight Self-Reset Mechanism: Achieves automatic reset through a counterweight rod, preventing air leakage.

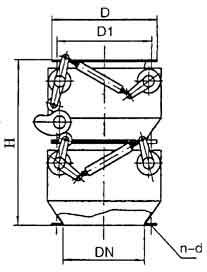

- Alternating Opening and Closing: The upper and lower gates of the double-layer flip gate valve open and close at different times, ensuring that at least one gate plate remains closed at all times to prevent air leakage.

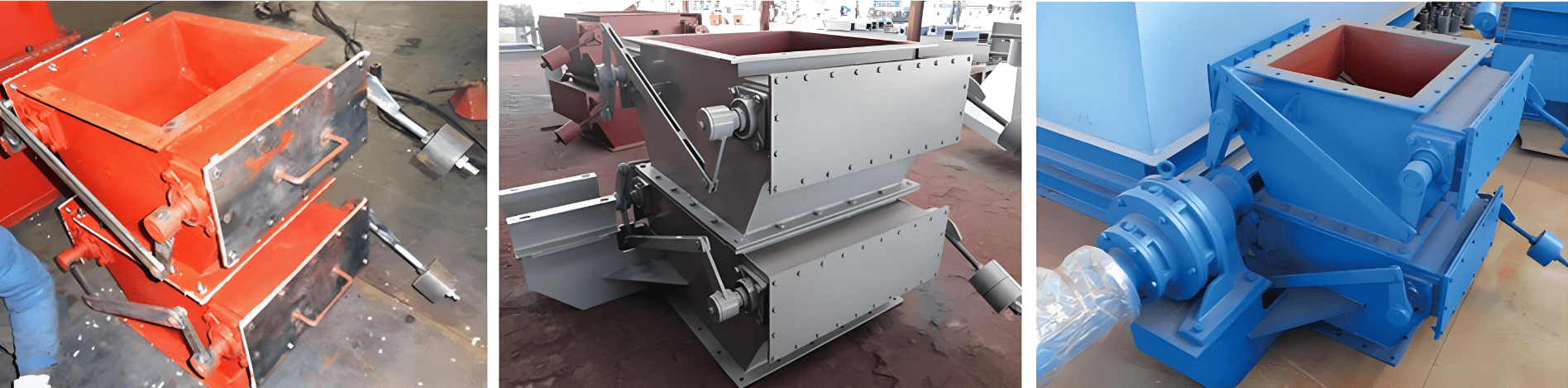

In terms of the automatic reset mechanism, the double flap airlock valve mainly consists of the following types:

- Counterweight Automatic Reset Mechanism : Features smooth operation, energy efficiency, adjustable ash discharge, and reliable sealing.

- Hanging Weight Automatic Reset Mechanism : Saves space, is energy-efficient, allows for easy adjustment of ash discharge, and ensures reliable sealing.

- Cam and Linkage Drive Automatic Reset Mechanism : Offers a compact structure, reasonable design, and smooth operation.

For more information or technical inquiries, please feel free to contact our sales team, and we will be happy to assist you.

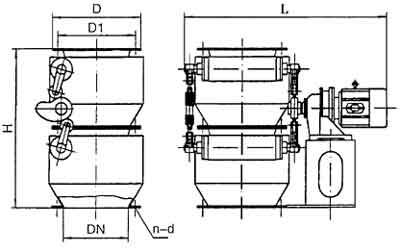

Drawing of double flap valve

Technical Data Sheet

|

Applicable media |

Operating temperature |

Ash discharge capacity |

|

dry powder |

150℃ |

1.5-300m3/h |

|

DN |

D1 |

D |

H |

H1 |

L |

n-d |

Ash discharge capacity m3/h |

Transmission model |

Opening and closing frequency/min |

power kw |

|

150 |

196 |

226 |

460 |

|

1400 |

6-Φ11 |

1.5~2 |

BWY-15-59 |

25 |

0.6 |

|

200 |

245 |

280 |

580 |

|

1500 |

8-Φ11 |

4~5 |

BWY-15-59 |

25 |

0.6 |

|

220 |

265 |

300 |

580 |

|

1540 |

8-Φ11 |

5~7 |

BWY-15-59 |

25 |

0.6 |

|

250 |

300 |

340 |

580 |

|

1610 |

12-Φ11 |

5~8 |

BWY-15-59 |

21 |

0.8 |

|

300 |

350 |

390 |

620 |

|

1840 |

12-Φ13 |

7~12 |

BWY-15-59 |

21 |

1.1 |

|

320 |

370 |

410 |

700 |

|

1980 |

12-Φ13 |

9~15 |

BWY-15-59 |

21 |

1.1 |

|

400 |

450 |

490 |

800 |

660 |

2060 |

12-Φ13 |

12~15 |

BWY-15-59 |

12 |

1.66 |

|

450 |

500 |

540 |

800 |

740 |

2180 |

12-Φ13 |

16~34 |

BWY-15-59 |

12 |

1.66 |

|

500 |

560 |

600 |

950 |

800 |

2210 |

12-Φ13 |

20~45 |

BWY-15-59 |

12 |

1.66 |

|

600 |

660 |

700 |

|

920 |

2310 |

16-Φ13 |

34~72 |

BWY-15-59 |

12 |

3.18 |

|

720 |

780 |

820 |

|

1060 |

2380 |

16-Φ13 |

51~110 |

BWY-15-59 |

12 |

3.18 |

|

800 |

870 |

920 |

|

1150 |

2420 |

16-Φ13 |

77~160 |

BWY-15-59 |

12 |

3.18 |

|

1000 |

1080 |

1140 |

|

1450 |

2640 |

20-Φ18 |

150~300 |

BWY-15-59 |

8 |

4.3 |

Related products