Why do you have to choose a lump breaker?

The main function of the cement lump breaker is to crush lumpy cement materials.

It can be installed horizontally or vertically at the outlet of the silo or at the front end of the flow control valve or pneumatic cut-off valve.

When larger lumps of material appear in the material, they can be crushed immediately. To prevent blocking the channel of the discharge valve and ensure smooth discharge.

With the development of the cement industry, higher demands have been placed on cement production. In the clinker calcination system, processes such as raw material homogenization, cooling, and grinding face challenges. These challenges arise due to the long workflow and high material temperatures, which can easily lead to pipe blockage. Therefore, appropriate measures must be taken to ensure the stable operation of the entire system.

Currently, most cement plants in China use a dual-silo method. In this method, the raw material silo and the cement mill operate simultaneously. This approach increases output and reduces costs. It also significantly minimizes losses caused by pipe blockages.

However, since this method requires both silos to operate at the same time, a blockage in one silo greatly affects the other. This can lead to a complete shutdown of the system. To address this issue, many plants have adopted mechanical arch breakers. A mechanical arch breaker consists of a shaft with rotating blades. These blades cut the incoming material, allowing it to be discharged from the pipeline. This action facilitates unblocking. However, this method is not only inefficient but also cumbersome to operate, leading to high labor intensity.

Performance characteristics

1. Reasonable and compact structure, easy to install, maintain and use.

2. The driving device is the reducer.

3. Crushing blade and cutter holder are made of high wear-resistant materials.

4. The crushing particle size is generally below 20mm, and the proportion of 20~30mm is less than 20%.

Working principle

The lump breaker can be operated by just one person to complete all cleaning tasks. By simply opening the valve and starting the motor, automatic cleaning can be achieved. If a blockage is detected, you only need to close the valve. Additionally, the breaker can operate continuously. Even if a certain position experiences a malfunction or power outage, it will not affect the production of other positions. Therefore, after using this breaker, not only can the labor intensity of workers be reduced, but work efficiency can also be improved.

The working principle of the crushing valve mainly consists of two parts: mechanical crushing and electric control. The mechanical crushing part is driven by a motor that rotates the drive pulley. The gearbox drives the eccentric block to rotate, generating centrifugal force that causes the moving hammer to swing and strike the material, producing vibration and impact to achieve the crushing effect.

The electric control part consists of an electric actuator and a hydraulic cylinder. When the operator presses the button, the motor drives the oil pump to work, moving the piston rod to open the sealing element. After the power is turned off, the electromagnet engages to release the locking screw and reset the sealing ring, allowing the switch action to be performed manually.

The reducer drives the blade shaft, which rotates and squeezes the block material between the blades and the cutter seat. As a result, this action effectively crushes the block material. Furthermore, if the block material is greater than 30mm, the blades repeatedly break it down until it passes through the grid. This ensures a consistent and efficient crushing process.

Structure selection parameters

The electric cement lump breaker crushes blocky materials in the warehouse or silo caused by moisture, ensuring smooth unloading.

The cement crushing valve installs horizontally or vertically at the feeding end of the unloading equipment, specifically at the unloading outlet. Furthermore, the crushing claws and grid plates, made of wear-resistant materials, enhance durability and simplify maintenance. This design makes the valve suitable for various gasification unloading tanks and storage unloading outlets.

Additionally, the cement lump breaker has gained significant promotion over the past two years due to the state's requirement for cement plants to minimize pollution during discharge. Consequently, operators must install the cement crushing valve at the bottom of the cement silo to comply with these regulations.

Moreover, Darko produces an electric cement lump breaker known for its good quality and favorable prices. Many cement plants now use it, and as a result, users have praised its effectiveness and reliability in the industry.

| Model | Effective size(mm) | Capacity(m³/h) | Maximum block material (mm) | Fluidization pressure (Kpa) | Air consumption (m3/min) |

|

GBPSF300 |

B30 |

300 |

<150 |

≥30 |

0.23 |

|

GBPSF400 |

B400 |

450 |

<200 |

≥30 |

0.30 |

|

GBPSF500 |

B500 |

600 |

<200 |

≥30 |

0.38 |

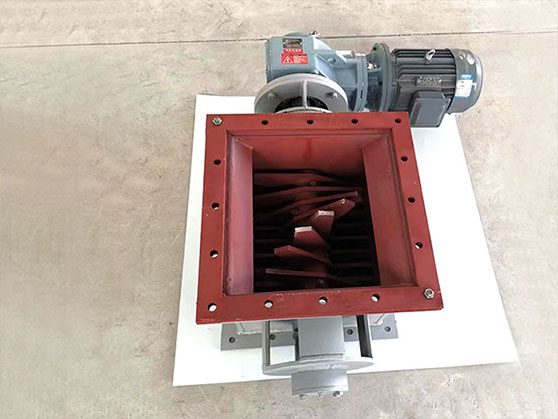

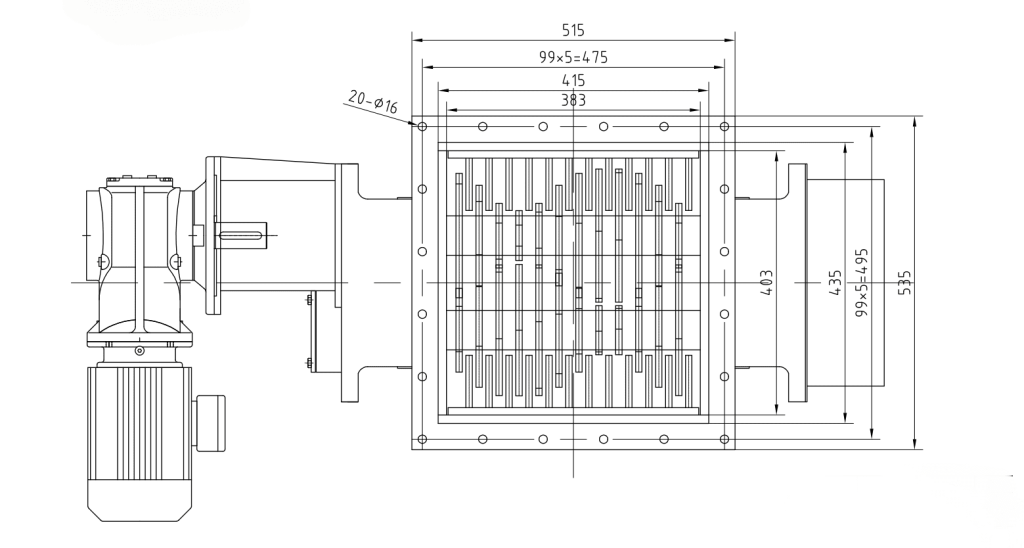

Appearance diagram of B500 lump breaker

Related blog posts

Key points for choosing cement lump breaker

You may also like