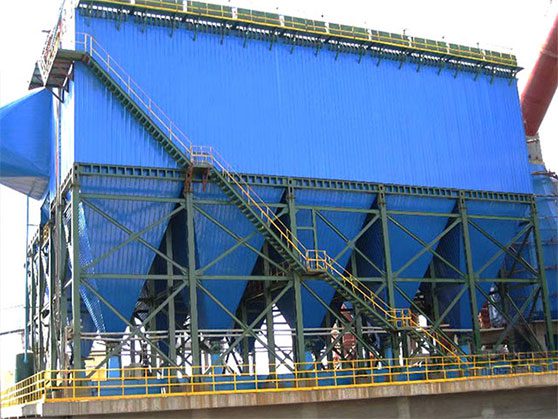

The rotary kiln tail dust collector mainly refers to the kiln outlet dust collection system for pre-calciner production lines with a capacity of over 1000 t/d. The characteristics of the exhaust gases are a large airflow and a high concentration (generally around 100 g/m³). The dust is fine and sticky, and contains alkali, making it a major emission point in cement plants. In foreign countries (especially in the United States and Canada), as environmental protection requirements become increasingly stringent, the use of baghouse dust collectors has become a trend.

The kiln tail baghouse utilizes P84 and fluoropolymer needle-punched felt filter bags to meet kiln tail gas emission requirements. It features advantages such as efficient filtration, low resistance, and multiple dust cleaning modes, which save energy and reduce footprint. Equipped with intelligent operation monitoring and an advanced filtration control system, kiln tail baghouse ensures efficient operation with emissions concentrations below 10 mg/m³.

Why does it has to use a rotary kiln tail dust collector ?

1. Low Emission Concentration

The dust emission standards in European countries are ≤ 25 mg/m³. Some regions in China have begun trialing a standard of ≤ 10 mg/m³. The emergence of various new filter materials has made it easier for baghouse dust collectors to meet these standards. These materials include membrane filter materials, waterproof and oil-resistant filter materials, and high-temperature Metas. In contrast, electrostatic precipitators find it more challenging to meet these standards.

2. Unaffected by Inlet Conditions

The outlet emissions of baghouse dust collectors are not influenced by variations in inlet conditions. The conditions of kiln tail outlet flue gas often change. These conditions include concentration, temperature, humidity, and particle size. Such changes can affect the specific resistance of the dust. This, in turn, impacts the efficiency of electrostatic precipitators. In contrast, kiln tail baghouse dust collectors capture dust through filtration. As long as they operate within a certain temperature range (e.g., fiberglass cloth usage temperature ≤ 250°C), their emission concentration is not affected by changes at the inlet.

3. Moderate Cost

The initial investment for a baghouse is lower than that for three-field electrostatic precipitators. In the past, baghouse dust collectors were generally perceived as large and space-consuming. However, advancements in filter material technology and components, such as pulse valves, have significantly improved the filtration air speed of baghouse dust collectors. This has led to reductions in both size and footprint. Particularly, the use of high-energy pulse baghouse has reduced their volume, footprint, and weight by about one-third. Conversely, as the air speed in electrostatic precipitators has gradually decreased, their size and footprint have increased. Additionally, the need to meet stricter emission standards has led to an increase in the number of electric fields. Typically, electrostatic precipitators have three fields in China, while some foreign systems have four. This results in higher investment costs.

4. Lower Cooling Requirements for Spray Tower Technology

The temperature of dry kiln tail outlet exhaust gases is generally above 380°C. These gases have a high specific resistance, typically above 10^12 Ω·cm. If using an electrostatic precipitator, it is necessary to use a humidification tower to condition the gases. This conditioning reduces the temperature to 130°C–150°C to ensure removal efficiency. In contrast, the kiln tail baghouses do not require such conditioning. They only need to reduce the temperature to below 250°C, which makes it easier to control. In addition to spray cooling, heat exchangers, such as multi-tube coolers, can also be used. This provides greater flexibility in options.

5. Online Maintenance and Management

The kiln tail baghouse dust collectors consist of relatively independent units. This design allows for cleaning, maintenance, or bag replacement in a specific unit. These activities can be carried out without affecting the operation of the entire system.

6. Good Safety

During the ignition and startup of the rotary kiln, incomplete combustion of coal powder can produce CO. If an electrostatic precipitator is used, this can lead to explosions during startup. This situation necessitates external discharge. Additionally, continuous monitoring of CO levels with CO analyzers is required during regular operation. This imposes strict maintenance and management requirements. In contrast, the use of kiln tail baghouse dust collectors minimizes these issues.

The main features

1. Wide Range of Airflow

The kiln tail bag dust collector can handle a wide range of airflow. Small units process just a few cubic meters per minute. Larger units can reach tens of thousands of cubic meters per minute. This capability makes it suitable for dust collection from industrial furnaces and kilns. It helps to reduce atmospheric pollutant emissions.

2. Simple Structure and Easy Maintenance

The design of kiln tail dust collector is straight forward, making maintenance and operation convenient. It offers a lower cost compared to electrostatic precipitators while ensuring the same high kiln tail dust removal efficiency.

3. Strong Adaptability

The kiln tail dust collector is effective across a wide range of concentrations. Fluctuations in inlet concentration and gas volume do not impact its kiln tail dust removal efficiency. They also do not affect pressure loss.

4. High Efficiency and Energy Saving

The rotary kiln tail dust collector utilizes pulse jet cleaning technology. This provides strong ash cleaning capability. It achieves high kiln tail dust removal efficiency. The emission concentration is low, and there is minimal leakage. It also has low energy consumption and reduced steel usage. Additionally, it has a smaller footprint. The operation is stable and reliable, resulting in good economic benefits.

5. Wide Applicability

The kiln tail baghouse is widely used for ash removal during the cement production process. It is primarily applied in environments such as the clinker rotary kiln, hot air furnace, and kiln tail. This kiln tail baghouse effectively reduces ash emission concentrations. It also helps protect the environment and employee health.

Dako kiln tail baghouse is a new type bag filter developed based on repeated investigations, sampling, and validation of domestic and international manufacturers of cement shaft kiln production. When selecting and using the kiln tail baghouse, multiple factors need to be considered. These factors should be based on actual conditions. Choosing the appropriate kiln tail baghouse can effectively reduce dust emissions. It can also improve environmental protection standards, lower production costs, and ensure the normal operation of the production line.