The silo discharge device is used for storage and transportation in cement plants or related industrial settings. Its main function is to safely and efficiently unload and transport cement or other powdered materials from the bottom of the cement silo. These devices utilize automated control to ensure ease of operation and safety. They also allow for adjustable unloading flow while maintaining uniformity.

Darko can also customize according to user's requirements

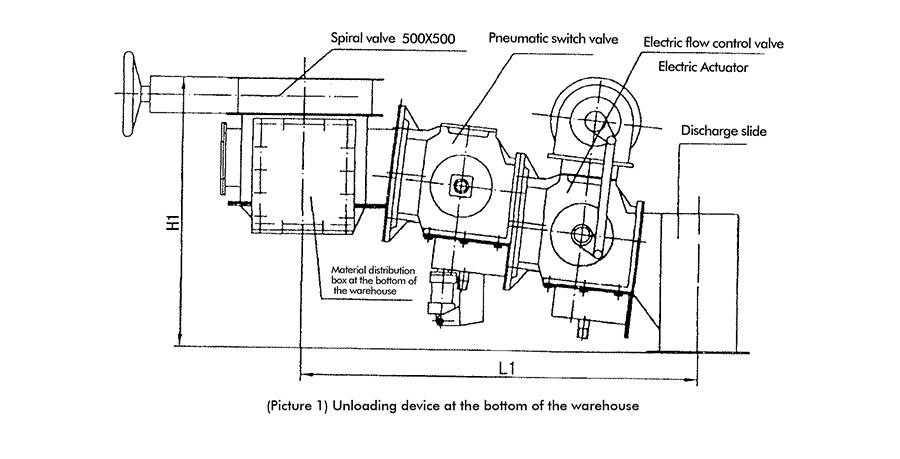

1. Composition of a discharge device

- Slide gate valve

- Diverting box

- Pneumatic on-off valve

- Electric flow control valve

- Discharge chute, etc.

2. Working Principle

»During unloading, the bottom slide gate is opened manually or automatically, allowing the material to flow out under the influence of gravity.

»The electric flow control valve adjusts the opening to ensure a constant flow rate of the material.

»The material passes through the discharge chute into the downstream conveying system or bulk loader, directly loading onto trucks or entering the next production stage.

3.Technical Data Sheet

| Specification

|

B250 | B315 | B400 | |

| Soft seal | Flow m3/h | 130 | 160 | 220 |

| Operating temperature℃ | <100 | <100 | <100 | |

| Maximum circulation area m | 0.0148 | 0.025 | 0.0425 | |

| Minimum center distance mm | 1180 | 1230 | 1410 | |

| Minimum height H(α=6°)mm | 830 | 830 | 1025 | |

| Rigid seal | Flow m3/h | 120 | 160 | 220 |

| Operating temperature℃ | <150 | <150 | <150 | |

| Maximum circulation area m2 | 0.0148 | 0.025 | 0.0425 | |

| Minimum center distance mm | 1350 | 1410 | 1410 | |

| Minimum height H(α=6°)mm | 830 | 830 | 1025 | |

| On/off valve | Cylinder | QGB 100×200-MP2 | QGB 100×200-MP2 | |

| The electromagnetic valve | KD25-8, 220V | |||

| Electric putter | DT100-20 | DT300-200 | ||

| Flow valve | Electric Actuator | DKJ-310/AS-25 | DKJ-410/BS-60 | |

4. Equipment Features

Efficient Unloading: Automatically adjusts unloading flow while ensuring uniform flow, improving work efficiency.

Sealing Performance: Features both soft and rigid sealing structures to adapt to different working conditions.

Easy Operation: High degree of automation, making operation and maintenance simple and convenient.

Strong Durability: Manufactured with German technology, using 16Mn steel for the valve core and housing, with a chrome-plated surface to enhance wear resistance.

5. Application Scenarios

Cement Plants: Used for storage and unloading of cement, meeting production line requirements.

Power Plants: Used for unloading by-products like fly ash, facilitating transportation and reuse.

Chemical Plants: Used for storage and unloading of chemical raw materials, ensuring production continuity.

6. Maintenance Methods

Regular Inspection: Periodically check the operational status of components, especially the sealing parts.

Lubrication Maintenance: Regularly lubricate moving parts to reduce wear and extend service life.

Sealing Performance Testing: Regularly check the sealing structures to prevent dust leakage and environmental pollution due to poor sealing.