Explosiones de polvo se producen cuando las partículas de polvo combustible suspendidas en el aire reaccionan con el oxígeno en condiciones específicas, liberando calor y presión extremos. Para mitigar estos peligros, las industrias deben adoptar colectores de polvo a prueba de explosiones diseñado para satisfacer ATEX y Normas NFPA.

Condiciones para la explosión de polvo

Cuatro factores clave deben alinearse para que un peligro de explosión de polvo que se produzca:

Partículas de polvo combustibles (lo suficientemente pequeño como para formar una nube).

Agente oxidante (normalmente oxígeno).

Fuente de ignición (por ejemplo, chispas, superficies calientes).

Espacio cerrado (por ejemplo, el filtro de mangas del colector de polvo).

Medidas antiexplosión para colectores de polvo

El objetivo principal es suprimir las explosiones en la fase inicial, garantizando que la presión interna se mantenga por debajo de 100 kPa. Un buen diseño sistema de captación de polvo a prueba de explosiones incluye:

1. Medidas de prevención eficaces

Evitar la acumulación de polvo en tuberías y equipos.

Controle las fuentes de ignición (sin llamas abiertas, chispas de soldadura ni descargas estáticas).

Utilice gases inertes (por ejemplo, nitrógeno) para reducir la concentración de oxígeno (común en Colectores de polvo con certificación ATEX).

2.Diseño estructural para la seguridad contra explosiones

Las tolvas colectoras de polvo deben tener pendientes >70° para evitar acumulaciones.

Instale elementos calefactores para evitar obstrucciones relacionadas con la humedad.

Las válvulas de regulación del flujo de aire equilibran la presión entre las cámaras (variación <5%).

3. Componentes a prueba de explosiones y conexión a tierra

Las válvulas de impulsos y los componentes eléctricos a prueba de explosiones eliminan el riesgo de chispas.

Una conexión a tierra adecuada evita la acumulación de electricidad estática (fundamental para el cumplimiento de la norma NFPA 652).

4. Protección contra la electricidad estática

Las bolsas filtrantes antiestáticas con fibras conductoras incrustadas (por ejemplo, de acero inoxidable) descargan la electricidad estática de forma segura.

5. Sistemas de detección de incendios y explosiones

La monitorización de CO y los sensores de temperatura activan las alarmas.

Supresión automática de incendios (CO₂ o nitrógeno) para zonas de alto riesgo.

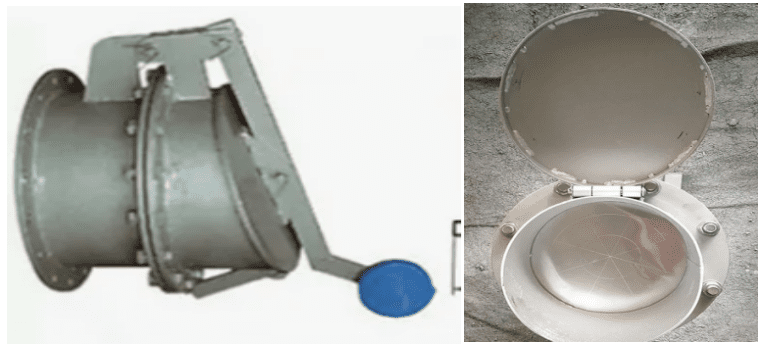

6. Diseño del venteo de explosión

Las membranas de venteo de explosión o los discos de ruptura liberan la presión a 5-10 kPa.

Los cálculos del área de ventilación siguen las directrices del valor Kst (relación normalmente de 1:5 a 1:50 frente al volumen del colector).

Componentes clave para colectores de polvo con certificación ATEX/NFPAC

1. Materiales filtrantes antiestáticos

Las bolsas filtrantes conductoras (por ejemplo, las mezclas de fibra de carbono) evitan las chispas estáticas.

2. Válvulas de impulsos a prueba de explosiones

Dos tipos: electroválvulas selladas o conjuntos integrados a prueba de explosiones.

3. Sistemas de extinción de incendios

- La inyección de CO₂/nitrógeno suprime los incendios automáticamente.

Conclusión

Mediante la aplicación de principios de diseño a prueba de explosiones, las industrias pueden cumplir las directivas ATEX y las normas NFPA 652, reduciendo significativamente los riesgos de explosión del polvo.

¿Busca un colector de polvo con certificación ATEX? Contacte con nosotros para soluciones antideflagrantes personalizadas y adaptadas a las necesidades de sus instalaciones.