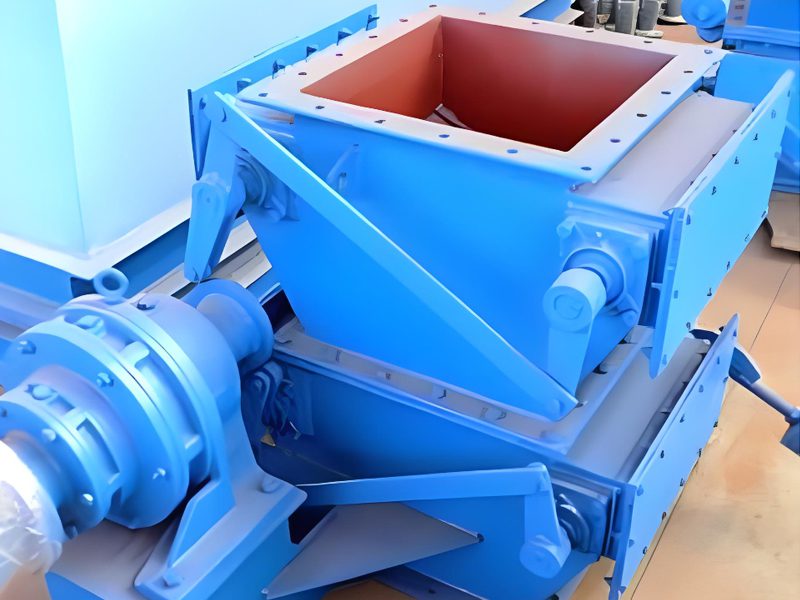

Introduction to Double Dump Valves

Double dump valves (also known as dual-flap valves o twin gate discharge valves) are essential components in powder and granular material handling systems. Widely used in cement plants, food processing, and metallurgy industries, these valves excel in:

✔ Make sure air doesn’t escape in pneumatic expressing systems.

✔ Ensuring continuous material flow control

✔ Providing airtight sealing for dust collection

1. Core Working Principle of Double Dump Valves

1.1 Basic Structure

Every double dump valve contains three critical components:

Upper and lower valve flaps (typically made of wear-resistant steel)

Heavy counterweight mechanism (for automatic flap reset)

Sealing gasket (usually food-grade rubber or PTFE)

1.2 Material Flow Process

The patented alternating flap system operates in 4 stages:

Upper flap opens – Material enters the intermediate chamber

Upper flap seals – Creates an airlock to prevent pressure loss

Lower flap discharges – Material exits by gravity

Lower flap resets – Counterweight ensures complete closure

Key Benefit: This sequential operation maintains constant system pressure while allowing uninterrupted material transfer – a critical advantage over rotary valves in high-pressure systems.

2. Electric Double Dump Valve Operation

2.1 Key Components

| Part | Function |

|---|---|

| IP65-rated actuator | Weatherproof electric motor drive |

| Chain/belt transmission | Converts rotary to linear motion |

| Position sensors | Provides open/close feedback to PLC |

2.2 Working Cycle

Opening Sequence:

① Motor energizes → ② Gearbox rotates shaft → ③ Upper flap opens (0-90°) → ④ Time delay (2-5 sec) → ⑤ Lower flap opens

Closing Sequence:

① Lower flap seals → ② Upper flap closes → ③ Limit switch signals completion

Pro Tip: Electric models achieve <0.5% leakage rates when paired with inflatable seals for abrasive materials like fly ash.

3. Pneumatic Double Dump Valve Mechanism

3.1 Air Cylinder Operation

Single-acting cylinders (spring return) for compact installations

Double-acting cylinders for high-speed cycling (up to 60 cycles/minute)

3.2 Critical Sealing Technology

En cone-and-spring sealing system provides:

Primary seal: Metal-to-metal contact between flap and seat

Secondary seal: Compressible elastomer gasket (FDA-approved options available)

Industry Application: Particularly effective in explosive environments (ATEX Zone 22) where electric sparks must be avoided.

Comparative Analysis: Electric vs Pneumatic

| Característica | Electric | Pneumatic |

|---|---|---|

| Response Time | 3-10 seconds | <1 second |

| Mantenimiento | Annual lubrication | Quarterly diaphragm checks |

| Uso de la energía | 0.5-2 kW | 4-6 CFM @ 80 psi |

| Best For | Precise positioning | Rapid cycling |

Troubleshooting Common Issues

Problem 1: Material bridging

Solución: Instale vibrators o air cannons on valve body

Problem 2: Seal degradation

Diagnosis: Check for excessive play in linkage arms (>3mm indicates wear)

Problem 3: Incomplete closure

Fije: Adjust counterweight position or increase cylinder pressure by 10%

Industry-Specific Applications

✔ Cement Plants

Handles clinker dust at 300°C with water-cooled bearings

✔ Food Processing

316 stainless steel models with sanitary clamps meet USDA standards

✔ Power Generation

Explosion-proof versions for coal fly ash collection

FAQs (Featured Snippet Optimization)

Q: How often should double dump valves be maintained?

A: Perform visual inspections weekly y complete overhaul every 2,000 operating hours

Q: Can double dump valves handle sticky materials?

A: Yes, when equipped with Teflon-coated flaps y air purge connections

Q: What's the typical lifespan?

A: 5-7 years for standard models, 10+ years with hardened alloy components

Technical Specifications Table

| Parameter | Range |

|---|---|

| Sizes | 4″ to 24″ diameter |

| Temperatura | -40°F to 750°F |

| Presión | Up to 15 PSI (standard) |

| Materiales | Cast iron, SS304, SS316, AR steel |

For double dump valve selection consultation or technical support, please contact us.