El rodillo transportador de banda es un componente esencial de cualquier cinta transportadora sistema. Hay rodillos de todo tipo y suponen alrededor de 35% de lo que cuesta un sistema transportador, además de crear más de 70% de la resistencia. Por lo tanto, la calidad de estos rodillos es extremadamente importante. Están disponibles tanto en acero como en materiales plásticos.

Finalidad de los rodillos transportadores de banda

La función principal del rodillo es soportar el peso de la cinta transportadora y de los materiales transportados. Los rodillos deben funcionar de forma flexible y fiable. Reducir la fricción entre la cinta transportadora y los rodillos es clave para prolongar la vida útil de la cinta, que representa más de 25% del coste total del transportador. Aunque los rodillos puedan parecer un componente pequeño con una estructura sencilla, fabricar rodillos de alta calidad es una tarea difícil.

Normas de calidad para rodillos transportadores de banda

Para determinar la calidad de un rodillo, tenga en cuenta los siguientes criterios:

- Desviación radial: La cantidad de desviación en la rotación del rodillo.

- Flexibilidad del rodillo: La facilidad con la que gira el rodillo.

- Movimiento axial: El grado de movimiento lateral a lo largo del eje del rodillo.

Tipos de rodillos transportadores

- Tipos de material:

- Rodillos de goma

- Rodillos cerámicos

- Rodillos de nylon

- Rodillos aislados

- Categorías principales:

- Rodillos de artesa: Incluye rodillos estándar, de inclinación hacia delante, de cambio rápido de rodamientos, de suspensión, de triple cadena, reversibles, de ángulo de artesa variable, de transición y en V.

- Rodillos paralelos: Incluye rodillos estándar, tipo peine, de inclinación hacia delante, compuestos de acero-caucho y en espiral.

- Rodillos autoalineables: Dispone de rodillos de uso general, reversibles por fricción, resistentes, cónicos, en espiral y combinados.

- Rodillos amortiguadores: Incluye placa de resorte, anillo amortiguador, amortiguador de alta resistencia, elasticidad ajustable y rodillos de suspensión.

Principio de funcionamiento

Los rodillos de las cintas transportadoras funcionan gracias a la fricción entre la cinta transportadora y el rodillo. Esta fricción hace girar el cuerpo del rodillo, el alojamiento del rodamiento, el rodamiento exterior y el anillo de estanqueidad. Trabajan mano a mano con la cinta transportadora para que el movimiento de materiales sea coser y cantar.

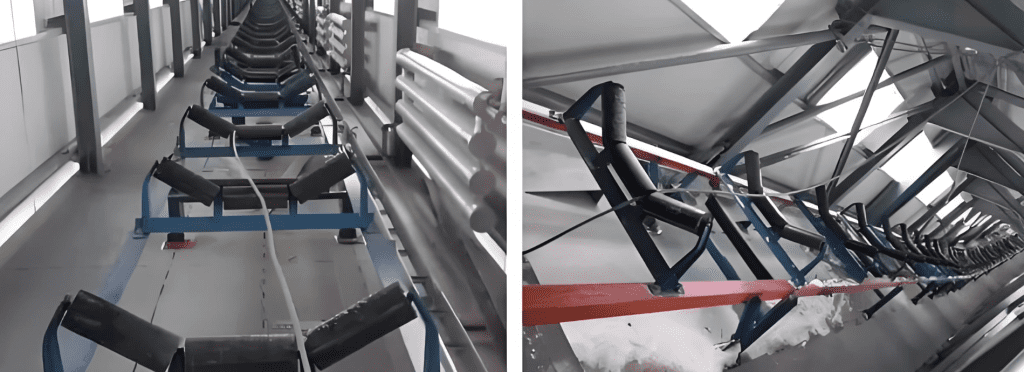

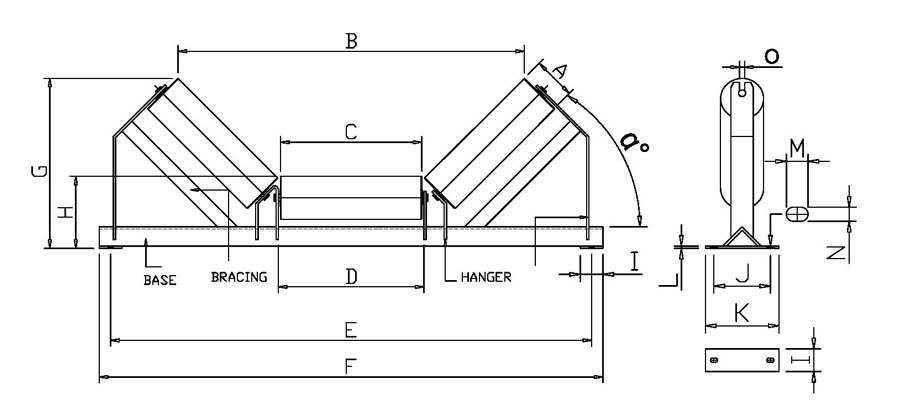

Comedero de tres rodillos

Este diseño estándar de rodillo se utiliza habitualmente en la mayoría de las aplicaciones de transportadores pesados. Fabricante Darko fabrican los rodillos de acero y a menudo los recubren con varias capas de pintura específica, caucho u otros materiales anticorrosivos.

Los rodillos pueden ser de acero, estar recubiertos de varias capas de una determinada especificación de pintura, o estar recubiertos de caucho o de otros materiales anticorrosivos.

Series de rodillos y aplicaciones

Estos rodillos son especialmente adecuados para transportadores que funcionan en condiciones difíciles, donde las cargas de trabajo son elevadas y se transportan trozos de gran tamaño. A pesar de estas exigencias, requieren un mantenimiento mínimo. Las aplicaciones típicas incluyen minas, cemento centrales eléctricas de carbón e instalaciones portuarias.

El sistema de sellado de rodillos aborda eficazmente retos medioambientales como polvo, la suciedad, el agua y las temperaturas extremas. Los componentes engrasados estándar funcionan bien dentro de una gama de temperaturas de -20°C a +100°C. Para aplicaciones fuera de este rango, pueden utilizarse grasa, cojinetes y juntas especiales.

También le puede gustar

|  |  |

|  |  |

Darko es uno de los fabricantes de filtros textiles de China. Suministramos a pequeñas y grandes empresas filtros de tela al por mayor seguros y con certificación ISO. Ofrecemos filtros de tela industriales de varias especificaciones y tamaños personalizados.

Darko lleva más de 10 años trabajando como fabricante y proveedor de filtros de tela de confianza en China. Con nuestros años de experiencia en el sector, podemos garantizar la producción de filtros de tela chinos de alta calidad. Además de la fabricación en nuestra propia fábrica, también ofrecemos servicios de personalización y diseño a nuestros clientes. Producimos filtros de tela para procesar diversos volúmenes de aire .

Si busca una empresa de filtros, puede confiar en Darko. Cómprenos filtros de tela al por mayor y permítanos ayudarle a hacer crecer su negocio utilizando nuestros productos personalizables y asequibles.