Dust removal technology for coal-fired boilers has come a long way. We’ve moved from using water film and baghouse systems to now relying on electrostatic precipitators (ESPs). However, with stricter environmental protection standards and the growing use of baghouse dust collectors, the limitations of electrostatic precipitators have become increasingly evident.

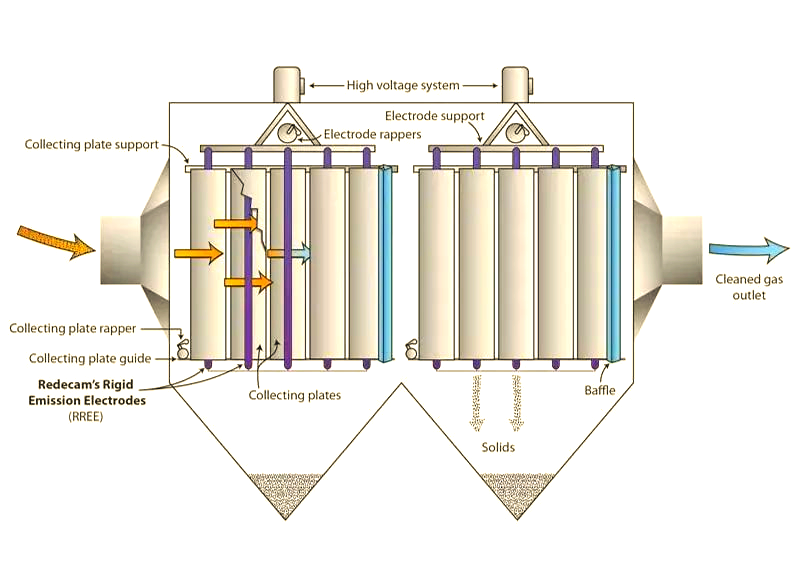

Efficiency and Challenges of Electrostatic Precipitators

Initially, electrostatic dust collectors can achieve a dust removal efficiency of up to 99%. Yet, variations in coal types and structural limitations can lead to deformation and ash accumulation in the internal components over time. This results in changes to the electric field, diminishing dust removal effectiveness, and causing emissions to exceed regulatory standards—a critical challenge for power plants. Also, the running costs for electrostatic dust collectors are pretty high. Frequent maintenance is required due to structural damage, which consumes considerable manpower and resources, leading to economic losses from production downtime. Plus, because electrostatic separators use a lot of power, people have started calling them the ‘electric tiger.’

Advancements in Baghouse Dust Collectors

Recent advancements in the production technology of baghouse filter materials have effectively addressed the challenges faced by baghouse dust collectors. Using offline maintenance technology has really improved how pulse jet baghouse dust collectors work for cleaning dust in boilers.

Stricter Emission Standards

As national environmental policies tighten, emission standards for boiler flue dust are continuously being raised. The newly released “Emission Standards for Pollutants from Thermal Power Plants” (GB13223) limits dust emission concentrations from coal-fired power plants to 50 mg/m³. Some local environmental protection agencies have introduced even stricter regulations, such as the “Beijing Comprehensive Emission Standard for Boiler Pollutants,” which has been in place since March 1, 2002. This standard imposes allowable concentrations for dust and sulfur dioxide emissions that are more stringent than many international benchmarks. Also, starting July 1, 2003, new rules on how businesses handle pollution fees came into play. These rules mean that if a company goes over the allowed emission limits, the fees they have to pay will double, which can really add to their operating costs.

Economic Perspective on Dust Collector Technologies

From an economic standpoint, the initial cost of pulse jet baghouse dust collectors is slightly higher than that of three-field electrostatic precipitators but comparable to or lower than that of four-field electrostatic separators As domestic production of key components, such as filter materials, accelerates, costs are expected to decline further. While electrostatic dust collectors have low resistance characteristics, with pressure losses of only 100–200 Pa, aiding in energy conservation, they also have notable drawbacks. Their large size requires substantial steel and necessitates high-voltage transformers and rectification equipment, leading to high initial investment costs. Also, when it comes to making, setting up, and running electrostatic separators, you really need to have some solid technical know-how.

Advantages of Baghouse Dust Collectors

In contrast, baghouse dust collectors offer significant performance advantages. Their dust removal efficiency can exceed 99% and is unaffected by the specific resistance of dust. They feature simple technical structures, stable and reliable operation, good adaptability to load changes, and easy management. Modern baghouse dust collector filter fabrics possess high-temperature resistance, waterproof, and oilproof characteristics, making them suitable for large flue gas volume boiler dust removal. Although the initial investment is lower than that of electrostatic precipitators, baghouse dust collectors are equipped with automated control functions, enhancing their operational efficiency.

If you have any questions or would like to learn more about our dust removal technologies for coal-fired boilers, please feel free to reach out to us. We’re here to help you find the best solutions for your needs.