Electrostatic precipitators and bag filters are two commonly used dust removal devices in the industrial sector. They differ significantly in working principles, performance characteristics, and application ranges.

1. Working Principle

- Electrostatic Precipitators: This device uses a high-voltage electric field to ionize the gas, which charges the dust particles. The charged dust particles move toward the collection plates and settle there due to the electric field force. Finally, methods like vibration remove the dust into a hopper. For example, in a coal-fired power plant, the electrostatic precipitator uses tens of thousands of volts of direct current to ionize the gas between the electrodes, producing many ions. The dust in the flue gas collides with these ions, becomes charged, and is then collected.

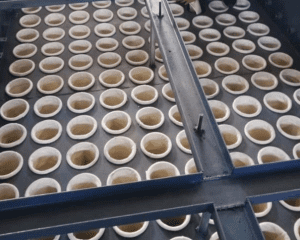

- Bag Filters: This device relies on fiber filter media to filter dust-laden gases. As the gas passes through the filter bags, dust particles get trapped on the surface of the bags while clean air passes through. Over time, dust accumulates on the filter bags, and cleaning methods like pulse jet or mechanical shaking remove the dust. For instance, in a cement plant, the bag filter filters the dust-laden gases produced during various stages of cement production.

2. Performance Characteristics

Dust Removal Efficiency

- Electrostatic Precipitator: Under ideal conditions, it can achieve over 99% efficiency for fine dust. However, the efficiency may be affected by high resistivity dust or changes in working conditions.

- Bag Filter: Generally, it has a very high dust removal efficiency, reaching over 99.9% for particles larger than 0.1 microns, reliably meeting strict emission standards.

Résistance

- Electrostatic Precipitator: It has low operating resistance, typically between 100-300 Pa, which results in lower energy consumption for the fan.

- Bag Filter: It has relatively high operating resistance, usually around 1000-2000 Pa, requiring more power to overcome this resistance, thus increasing energy consumption.

Handling Air Volume

- Electrostatic Precipitator: It can handle large volumes of flue gas, making it suitable for large industrial projects like coal-fired power plants, where a single unit can process millions of cubic meters per hour.

- Bag Filter: It can also handle significant air volumes, but for the same specifications, it may be larger in size when dealing with very high volumes.

Service Life

- Electrostatic Precipitator: With a relatively simple structure, key components like the electrodes can last 15-20 years if maintained properly.

- Bag Filter: The filter bags have a limited lifespan, typically 2-5 years, requiring periodic replacement, which increases maintenance costs and workload.

3. Application Range

- Electrostatic Precipitator: It suits high-temperature, high-humidity, and large-volume scenarios with moderate dust resistivity, such as in power generation and metallurgy. For high resistivity dust (like some sintering dust), special measures may be needed to enhance dust removal efficiency.

- Bag Filter: It effectively removes various industrial dust types, especially those that are sticky, hygroscopic, or pose explosion risks. It is widely used in industries with strict emissions requirements, like pharmaceuticals and electronics. However, its operating temperature is limited by the filter material, typically between 120-260°C.

4. Investment and Operating Costs

Investment Costs

- Electrostatic Precipitator: The equipment has a complex structure and uses a lot of steel, leading to high initial investment costs, especially when handling large volumes of flue gas.

- Bag Filter: Comparatively, it has a simpler structure and usually lower initial investment costs. However, using high-performance filter materials can increase expenses.

Operating Costs

- Electrostatic Precipitator: It has low operating resistance and energy consumption, but it requires a robust power supply system and regular maintenance of components like electrodes, leading to stable maintenance costs.

- Bag Filter: Due to high operating resistance, it has higher energy consumption for the fan, and the need for regular filter bag replacements increases overall operating costs, especially for replacement expenses.

5. Performance Comparison

1.Dust Removal Efficienc

- Electrostatic Precipitator: It effectively captures fine dust (like PM2.5), often achieving over 99%.

- Bag Filter: It also has high efficiency, especially for fine particles, reaching over 99.9%.

2.Application Range

- Electrostatic Precipitator: It is suitable for handling high-temperature, high-humidity, and high-concentration flue gases, commonly used in power, metallurgy, and cement industries.

- Bag Filter: It applies to various dust types, especially effective for sticky and moist dust, widely used in chemical, food, and pharmaceutical industries.

3.Operating Resistance

- Electrostatic Precipitator: It has low resistance, typically between 200-300 Pa.

- Bag Filter: It has higher resistance, usually between 1000-1500 Pa, requiring regular cleaning to maintain low resistance.

4.Energy Consumption

- Electrostatic Precipitator: It consumes less energy, mainly for high-voltage power supply and cleaning devices.

- Bag Filter: It has higher energy consumption, primarily from the fan and cleaning system.

5.Maintenance Costs

- Electrostatic Precipitator: It has lower maintenance costs, but electrodes and cleaning devices need regular upkeep.

- Bag Filter: It incurs higher maintenance costs due to regular filter bag replacements and cleaning system maintenance.

6.Service Life

- Electrostatic Precipitator: It lasts longer, with electrodes and collection plates usable for many years.

- Bag Filter: It has a shorter lifespan, typically 2-5 years, requiring regular bag changes.

6. Pros and Cons

1.Electrostatic Precipitator

Avantages:

- High dust removal efficiency, especially for fine particles.

- Low operating resistance and energy consumption.

- Suitable for high-temperature, high-humidity, and high-concentration flue gases.

Inconvénients:

- High initial investment costs.

- Sensitive to dust resistivity, requiring parameter adjustments.

- High maintenance workload.

2.Bag Filter

Avantages:

- High dust removal efficiency, particularly for fine particles.

- Wide application range, capable of handling various dust types.

- Lower initial investment costs.

Inconvénients:

- High operating resistance with increased energy consumption.

- Regular replacement of filter bags increases maintenance costs.

- Not suitable for high-temperature and high-humidity flue gases.

7. Recommendations for Selection

1.Electrostatic Precipitator: It is ideal for high-temperature, high-humidity, and high-concentration flue gas environments, especially where fine dust removal is crucial, such as in power, metallurgy, and cement industries.

2.Bag Filter: It is suitable for handling various dust types, particularly sticky and moist dust, widely used in chemical, food, and pharmaceutical industries.

Conclusion

Electrostatic precipitators and bag filters each have their own advantages and disadvantages. When choosing between them, consider specific operating conditions, dust characteristics, operating costs, and maintenance requirements.

Explore the differences between electrostatic precipitators and bag filters with Darko. For more information or inquiries, please feel free to nous contacter. Additionally, for more details on bag filters, visit our website. We are here to assist you with your dust removal needs!