PTFE (Polytetrafluoroethylene) sacs filtrants are widely used in industrial baghouses and filtration systems due to their excellent chemical resistance and high-temperature performance. When installing PTFE filter bags, it is crucial to follow the correct steps and precautions to ensure their effectiveness and longevity. Here are some key considerations:

1. Choose the Right Filter Bag

- Filtration Precision: Select the appropriate filtration precision based on your application to effectively remove target particles.

- Size Matching: Ensure the filter bag size matches the baghouse size to avoid leakage and efficiency loss.

2. Prepare the Installation Environment

- Cleanliness: Make sure the installation area for the filter bags and baghouse is clean to avoid contamination.

- Equipment Inspection: Check that the baghouse equipment is intact and free from damage or corrosion.

3. Pre-Installation Preparation

- Check the Filter Bag: Inspect the filter bag carefully before installation to ensure it is not damaged or dirty.

- Protective Gear: Wear appropriate protective gear, such as gloves and masks, during installation for safety.

4. Important Details

When installing PTFE filter bags, pay special attention to the following details to ensure stable long-term operation and maximize filtration efficiency and lifespan.

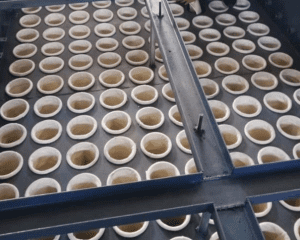

First, inspect the cage thoroughly before installation. Ensure the cage surface is smooth and free of burrs to prevent scratching the PTFE filter bag during installation or use. While PTFE material has excellent corrosion and wear resistance, excessive friction can still cause damage, affecting sealing and lifespan.

Second, handle the filter bag gently during installation. Avoid excessive stretching or twisting. Although PTFE filter bags are flexible, improper installation can damage their internal structure, affecting filtration performance. Use specialized tools to assist with installation, ensuring the bag fits smoothly and vertically onto the cage.

Next, ensure the seal between the filter bag and the header plate is secure during installation. PTFE filter bags typically connect tightly to the header plate using elastic bands or specially designed sealing structures. Check the sealing area carefully to ensure it is free from debris and misalignment. Use the appropriate force to tighten the fastening device to prevent air leaks or loosening.

5. Correctly Install the Filter Bag

- Direction: Follow the manual instructions to ensure the filter bag is installed in the correct direction.

- Securely Fasten: Make sure the filter bag is firmly secured in the baghouse to prevent it from falling or shifting during operation.

6. Pre-Operation Checks

- Leak Check: Before running the equipment, check for any leaks to ensure a good seal.

- Function Test: Operate the baghouse to conduct a function test and ensure the filter bags are working properly.

7. Regular Maintenance

- Pressure Monitoring: Regularly check the system pressure to ensure the filter bags are not clogged.

- Cleaning and Replacement: Depending on usage, regularly clean or replace the filter bags to maintain filtration efficiency.

8. Post-Installation Inspection and Testing

After installation, conduct a comprehensive inspection and testing. Check that the filter bags are properly installed, the seals are good, and the entire baghouse is operating normally. Simulate or perform actual running tests to identify and resolve potential issues, ensuring the PTFE filter bags achieve optimal performance when officially in use.

Conclusion

The installation and use of PTFE filter bags require meticulous attention to detail. From inspecting the cage and gentle handling to ensuring seals and comprehensive testing, every step is crucial. Only by doing so can you fully leverage the advantages of Sacs filtrants en PTFE, providing stable and efficient dust collection solutions for industrial production.For more information or support, please feel free to nous contacter. We are happy to assist you!