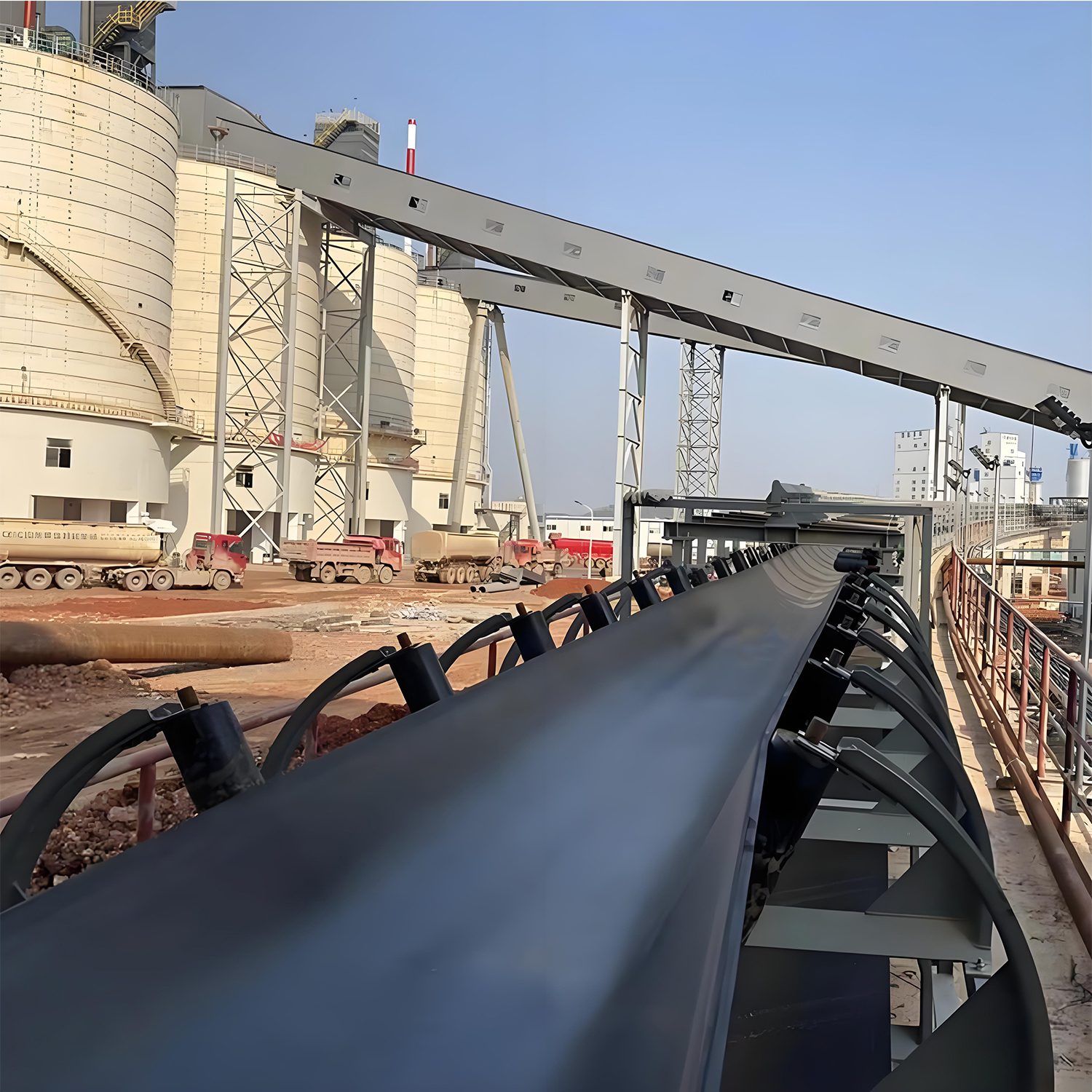

ベルトのハイライト Conveyor system

ベルト conveyors have strong conveying capacity, long conveying distance, simple structure, easy maintenance, and can easily realize program control and automatic operation. Utilize the continuous or intermittent movement of the conveyor belt to convey items under 100KG or powdery or granular items. The belt transport system has high and stable running speed, low noise, and can convey uphill and downhill. Darko as the belt conveyor manufacturer customized for incline, decline, or horizontal transport system.

The conveyor belt system moves according to the principle of friction transmission. It is suitable for conveying powdery, granular, small-block low-abrasive materials and bagged materials that are easy to dig out, such as coal, gravel, sand, セメント肥料、穀物など

The belt conveyor operates effectively in ambient temperatures ranging from -20℃ to +40℃, with the conveyed material’s temperature not exceeding 60℃. Users can determine its length and assembly form based on their specific requirements. The transmission can adopt an electric ローラー またはドライブフレームを備えたドライブ装置。

The belt conveyor is a friction-driven, continuous material conveying machine. It mainly consists of a frame, belt, ローラーs, tensioning device, and transmission device. The belt conveyor can transport materials from the initial feeding point to the final unloading point along a specific conveying line. It can convey both broken materials and finished items. In addition to pure material conveying, the belt conveyor also meets the requirements of various industrial processes. This capability allows it to form a rhythmic flow operation transportation line.

輸送能力パラメーター

| ベルト幅

mm |

ベルト速度 (m/s) | |||||||||

| 0.80 | 1.00 | 1.25 | 1.60 | 2.00 | 2.50 | 3.15 | 4.00 | 5.00 | 6.50 | |

| 搬送能力(t/h) | ||||||||||

| 500 | 69 | 87 | 108 | 139 | 174 | 217 | ||||

| 650 | 127 | 159 | 198 | 254 | 318 | 397 | ||||

| 800 | 198 | 248 | 310 | 397 | 496 | 620 | 781 | |||

| 1000 | 324 | 405 | 507 | 649 | 811 | 1014 | 1278 | 1622 | ||

| 1200 | 593 | 742 | 951 | 1188 | 1486 | 1872 | 2377 | 2971 | ||

| 1400 | 825 | 1032 | 1321 | 1652 | 2065 | 2602 | 3304 | 4130 | ||

| 1600 | 2188 | 2733 | 3440 | 4373 | 5466 | |||||

| 1800 | 2795 | 3494 | 4403 | 5591 | 6989 | 9083 | ||||

| 2000 | 3470 | 4338 | 5466 | 6941 | 8676 | 11277 | ||||

| 2200 | 6843 | 8690 | 10863 | 14120 | ||||||

| 2400 | 8289 | 10526 | 13158 | 17104 | ||||||

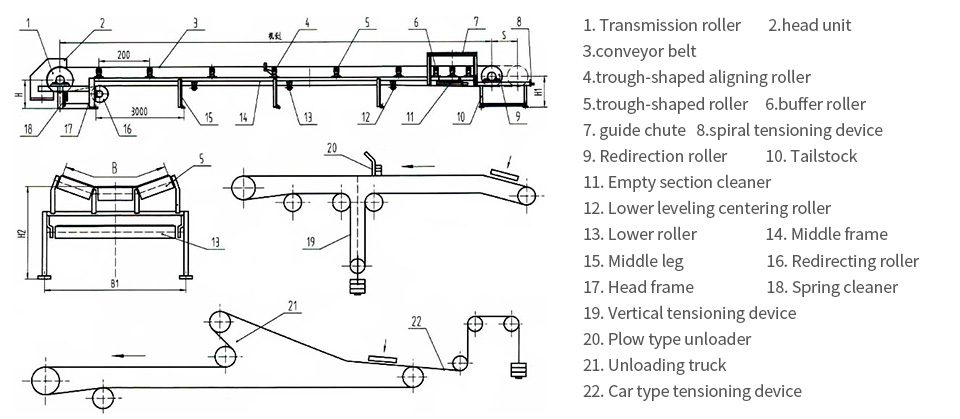

Belt Conveyor Drawing

適用範囲

ベルトコンベヤは水平と傾斜の両方で材料を輸送します。ベルトコンベヤは使い勝手がよく、現代のさまざまな産業企業で広く使われています。地下鉱山トンネル、地上輸送システム、露天掘り採鉱現場、鉱物処理工場などです。輸送プロセスの要件に応じて、オペレーターは単一のユニットを輸送に使用することができます。また、複数のユニットを他の輸送機器と組み合わせることもできます。このような柔軟性により、水平搬送システムや傾斜搬送システムを構築することができます。これらのシステムは、さまざまな生産ラインレイアウトのニーズに対応します。