In many industrial environments, managing dust is crucial for ensuring safety and production efficiency. This is especially true when dealing with flammable or explosive dust. The ATEX集塵機 is specifically designed to meet this need. This article explores its working principles, main features, applications, and factors to consider when choosing one.

What is an ATEX Dust Collector?

The ATEX dust collector is designed to comply with the European ATEX directive, which pertains to equipment and protective systems for use in potentially explosive environments. This directive ensures that the equipment used in such environments is safe and reliable. The ATEX dust collector effectively removes dust from the air, reducing the risk of explosions and fires.

動作原理

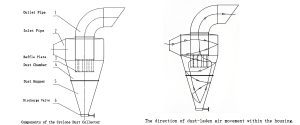

The ATEX dust collector operates through several key steps:

- エアインテーク: Dust-laden air enters the collector through the inlet.

- ろ過: The air passes through a high-efficiency filter, trapping dust particles while clean air exits through the outlet.

- ダストクリーニング: The system regularly or automatically removes dust from the filter to maintain efficient operation.

- Safe Emission: The treated clean air is safely released, meeting environmental standards.

主な特徴

- Explosion-Proof Design: The structure and materials of the ATEX dust collector are specially designed to prevent flame and pressure propagation in case of dust explosions.

- High-Efficiency Filtration System: It features a high-efficiency filter that captures fine particles, ensuring low emissions.

- Automatic Dust Cleaning: Many models include an automatic dust cleaning system, reducing manual maintenance and improving production efficiency.

- Modular Design: The flexible modular design allows it to adapt to various industrial needs.

アプリケーション

ダーコ's ATEX dust collectors are widely used in several industries, including:

- 化学工業: They handle dust generated from flammable chemicals.

- Pharmaceutical Industry: They ensure safe dust management during production.

- 食品加工: They control dust in food production to maintain hygiene and safety.

- 木工: They manage wood chips and other wood-related dust.

Comparison with Other Dust Collectors

When choosing a dust collector, other types are available, such as baghouse dust collectors and electrostatic precipitators.

- Baghouse Dust Collectors: These typically handle most industrial dust and offer good filtration efficiency but may lack explosion-proof features, making them suitable for non-flammable dust.

- Electrostatic Precipitators: These use electrostatic principles to capture dust. They are suitable for specific applications but may not be safe for flammable or explosive dust.

In contrast, the ATEX dust collector is specifically designed for handling flammable and explosive dust, providing higher safety and reliability in high-risk environments.

Factors to Consider When Choosing an ATEX Dust Collector

When selecting an ATEX dust collector, consider the following factors:

- Dust Characteristics: Understand the type, particle size, and explosiveness of the dust to be handled.

- Working Environment: Evaluate the environmental conditions, including temperature and humidity, where the equipment will operate.

- Processing Capacity: Choose a model based on the required processing capacity and airflow.

- Maintenance Requirements: Opt for equipment that is easy to clean and maintain to reduce operating costs.

結論

The ATEX dust collector plays a vital role in managing flammable and explosive dust. Its effective design and filtration system enhance safety and ensure compliance with environmental standards. Understanding the features and applications of the ATEX dust collector will help businesses achieve higher production efficiency and safety standards.

If you need more information or have any questions, please feel free to お問い合わせ. We are happy to provide you with professional advice and solutions.