ボイラーバッグハウス集塵機は、様々なボイラーシステムで使用される主要な産業機器です。その主な機能は、排ガスから粒子状物質をフィルタリングして捕捉することです。このプロセスは、効果的に粉塵を除去し、排出品質を向上させ、空気の質を高め、環境保護を支援します。

ボイラーバッグハウス集塵機の選択に関する考察

を選択する。 ボイラーバッグハウス集塵機最適な性能を確保し、環境規制を遵守するためには、いくつかの要素を考慮しなければならない。

1.ボイラーの仕様を理解する

まず、以下の点を評価する。 ボイラーの燃焼方法と定格出力。たとえば、石炭焚きボイラーの場合、石炭の種類、燃焼方法、排ガス量を理解することが重要である。この情報は、適切な集塵機を選択するのに役立つ。

2.環境方針の遵守

次に、地域の環境政策と排出基準に注意する。選択した集塵機がこれらの要件を満たしていることを確認する。規制が厳しい地域では、環境への影響を最小限に抑えるために、より高性能の集塵機が必要になる場合があります。

3.粉塵特性の分析

さらに、粉塵の物理的・化学的特性を理解することも極めて重要である。この知識は、適切なフィルター素材とクリーニング方法を決定するのに役立ちます。可燃性または爆発性の粉塵の場合は、安全性を確保するために防爆機能を備えた集塵機を選択します。

4.プロセスの流れを考える

プロセス全体の流れを理解することも重要である。最適な効果を得るために、ダストコレクタを取 り付ける最適な場所を決定する。プロセスによっては、集塵機を排ガス排出の前に設置することで、下流の機器への影響を減らすことができる。

5.気候条件の影響

さらに、温度、湿度、風などの地域の気候条件も考慮する。集塵機に適した材料と構造を選ぶ。高温多湿の地域では、安定性と長期的な性能を確保するために、防水性と耐腐食性を備えた集塵機を選択する。

6.特別な環境ニーズへの対応

最後に、高温、高湿、腐食性環境などの特殊な状況には、特殊機能を備えた集塵機を選択する。腐食環境では、装置の寿命を延ばすために防錆機能を備えた集塵機を選択する。

ボイラー集塵機の動作原理

ボイラーバッグフィルターは、バッグフィルターの原理を利用して、排ガスから粒子状物質を捕捉し、ガスを浄化して環境を保護します。前処理後、排ガスは集塵機に入ります。ガスはバッグフィルター層を通過し、粒子はバッグ表面に捕捉されます。浄化された排ガスは出口から排出されます。

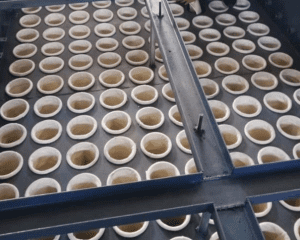

集塵機のバッグは高温耐摩耗性材料で作られています。高温の排ガスの衝撃や摩耗に耐えることができる。さらに、集塵機はコンパートメント化されたストップフローパルスジェット洗浄方式を採用しています。この方法は、長い洗浄サイクルと低いエネルギー消費を実現します。

さらに、集塵機はトップバッグ抽出方式を採用している。バッグ交換の際、骨組みを簡単に取り外すことができ、作業が容易になります。入口と出口の通路がコンパクトに配置されており、通気抵抗が少ない。低温によるガス結露を防ぐため、断熱材を装備しています。