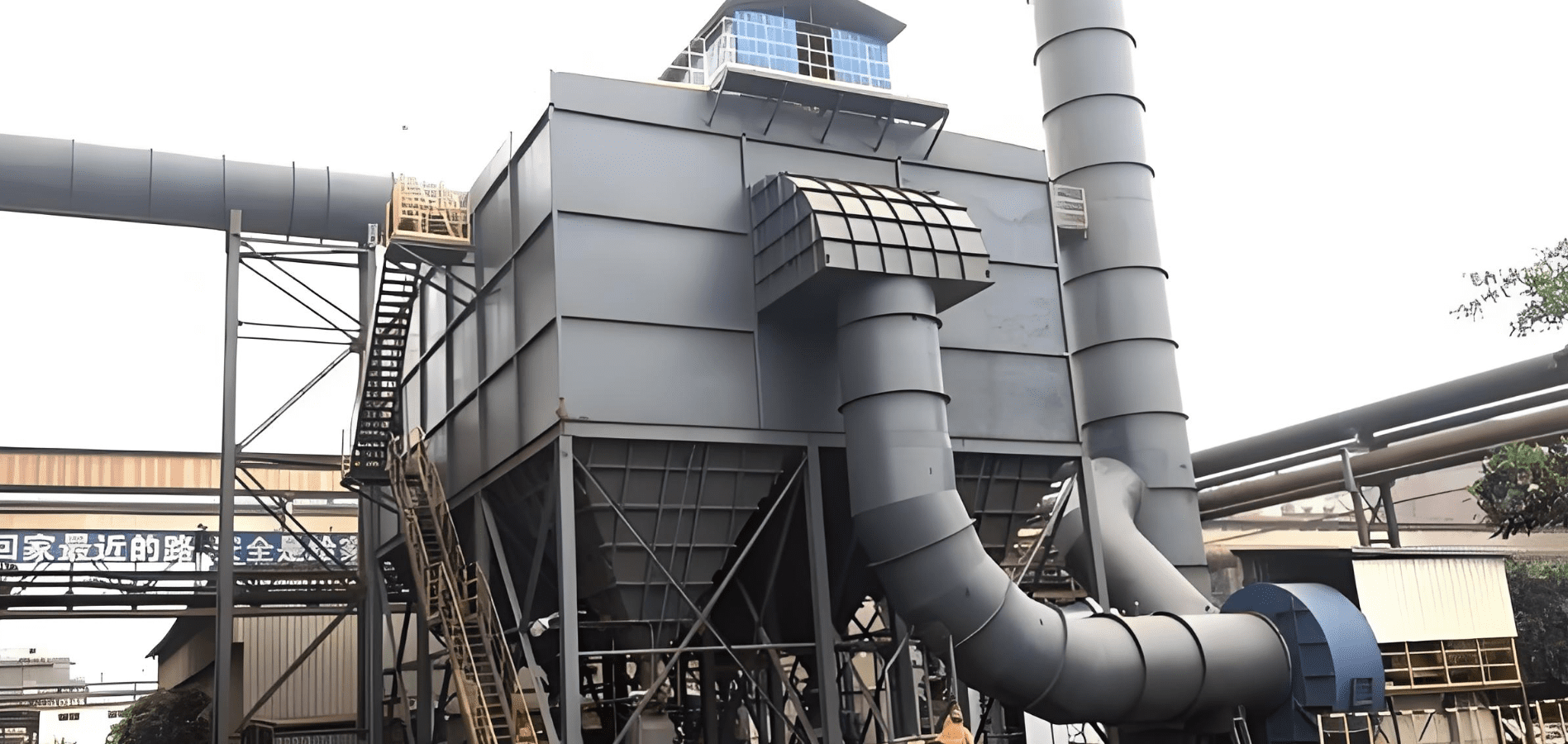

The dust collector project at Hebei Qianbao Special Cement Co., Ltd. features advanced equipment, including PPCS air box pulse dust collectors and HMC single-machine pulse dust collectors. These systems are designed to enhance air quality and meet stringent environmental standards across the cement production process.

At Nantong Darko Building Materials Machinery, we leverage state-of-the-art laser cutting technology for our dust collector panels. This innovative approach not only guarantees the smoothness of the panels but also facilitates precise processing of panel holes. As a result, this significantly enhances the overall efficiency and reliability of our dust collection system. By adopting such advanced technology, we ensure that our products meet the highest standards of performance.

As a comprehensive high-tech enterprise, Nantong Darko seamlessly integrates research and development, design, manufacturing, and installation. With our foreign trade rights, import and export credentials, and construction engineering qualifications, we are well-equipped to serve clients on a global scale.

Our team is composed of highly skilled designers and technical experts who specialize in dust collector manufacturing. We take great pride in our professional processing and production capabilities. Additionally, our exceptional after-sales service ensures that our clients can operate with confidence and peace of mind.

Dust Collector Project Background

Hebei Qianbao Special Cement Co., Ltd. operates a white cement production line with a capacity of 1,800 tons per day. The project handles a gas volume of 240,000 m³/h, achieving efficient dust removal while adhering to environmental protection standards. Additionally, the system is designed for easy operation.

Advantages of our dust collectors

High Dust Removal Capability

Our modern dust collectors employ advanced filtering technologies, such as bag filtration, electrostatic dust removal, and wet dust removal. By integrating these innovative methods, we efficiently capture dust particles of various sizes, achieving an impressive capture efficiency of up to 99.9%. Consequently, our systems ensure that emissions consistently meet or exceed strict environmental standards. This commitment to excellence not only enhances air quality but also supports our clients in maintaining compliance with regulations.

Multi-Stage Filtration System

By implementing a multi-stage filtration system, we further enhance the dust capture rate. This ensures that even fine dust is effectively captured, thereby reducing secondary pollution.