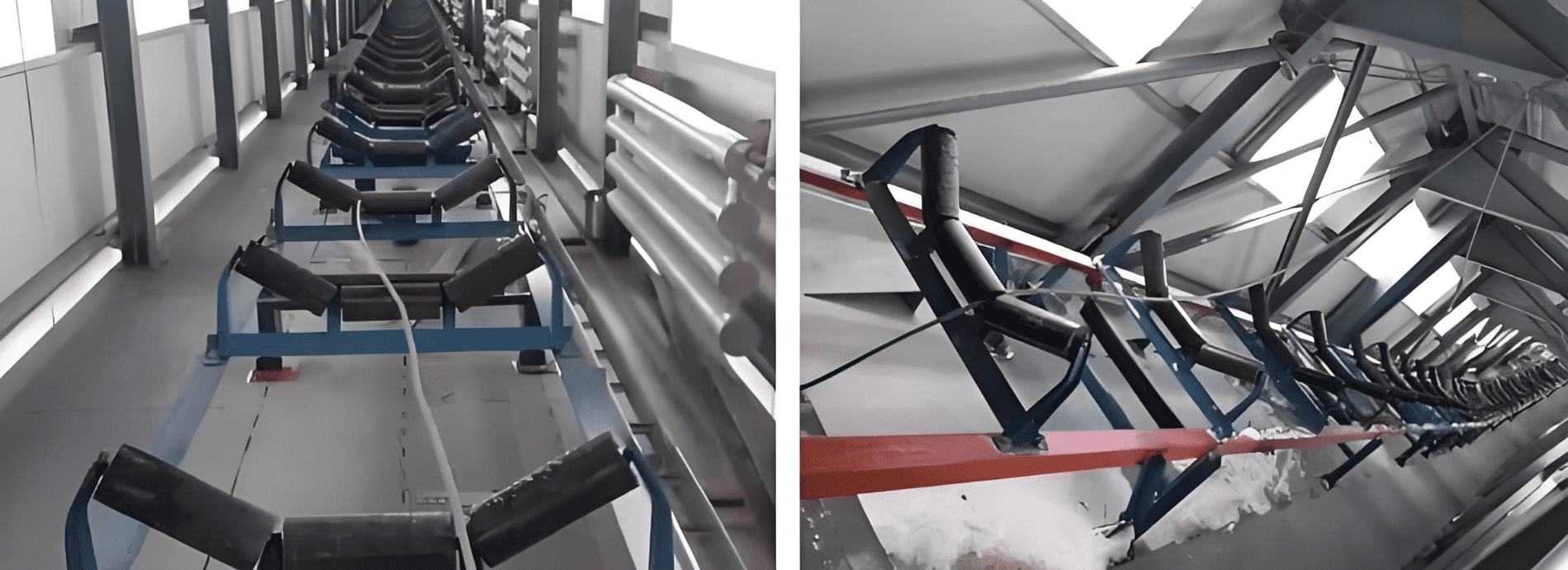

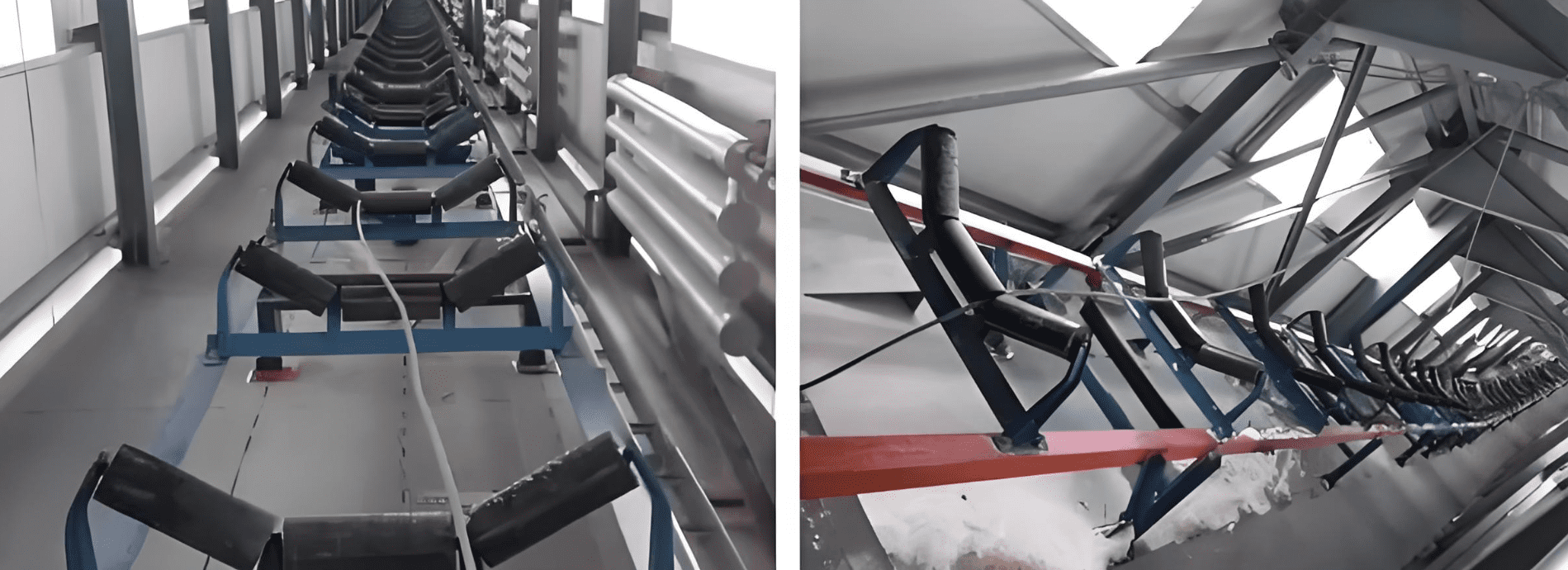

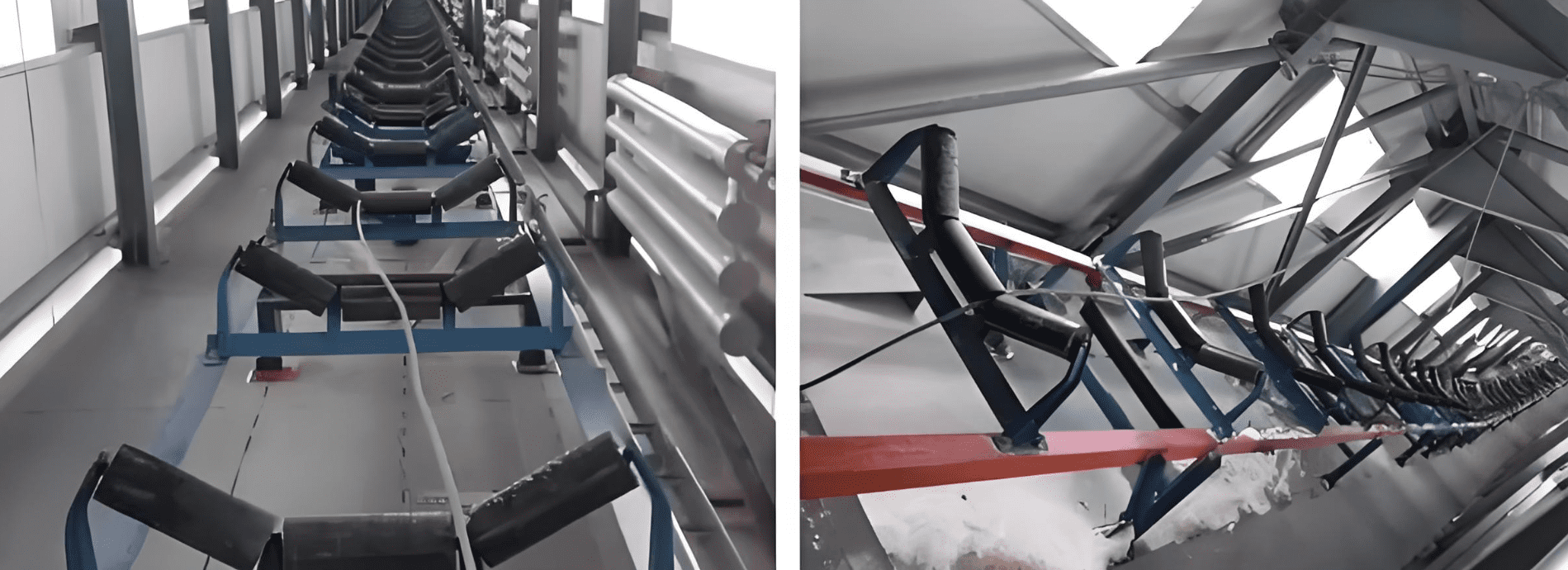

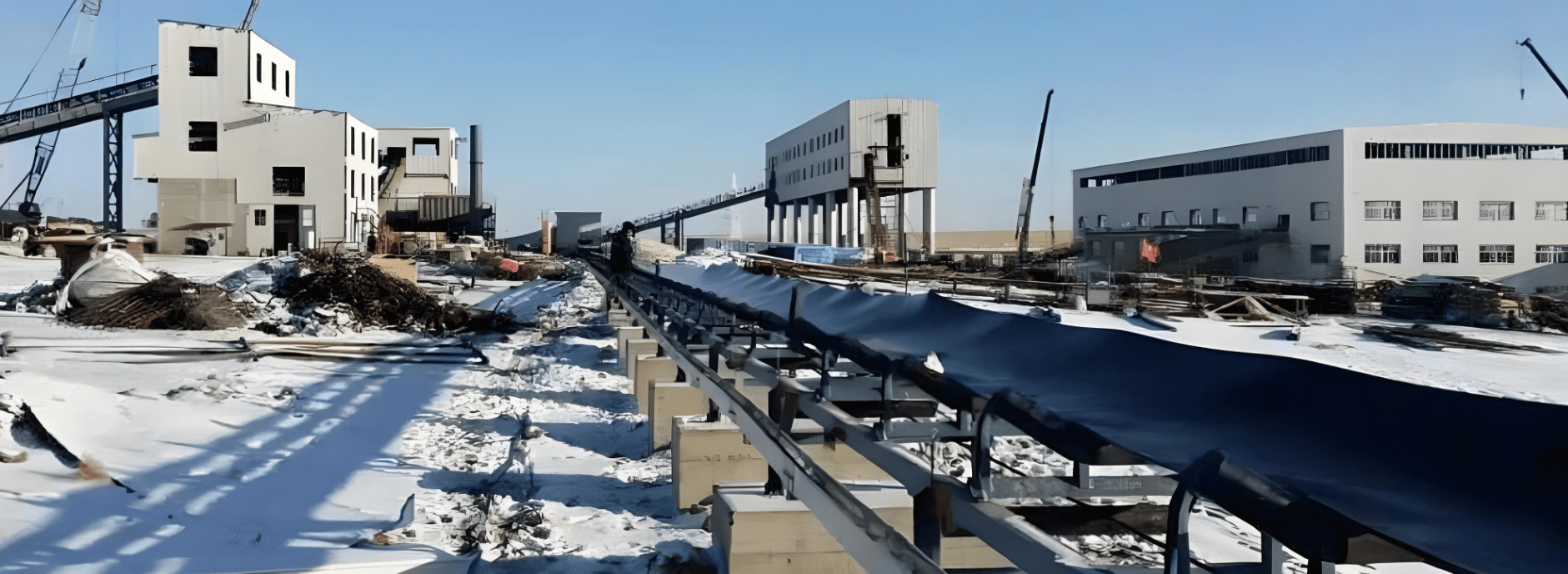

The DTII Belt Conveyor Project, manufactured by Nantong Darko Building Materials Machinery, showcases robust conveying capacity and an extensive conveying distance. This advanced system features a simple structure that allows for easy maintenance, ensuring operational efficiency and minimal downtime. Moreover, the project seamlessly integrates program control and automatic operation, significantly enhancing overall productivity and reliability in material handling.

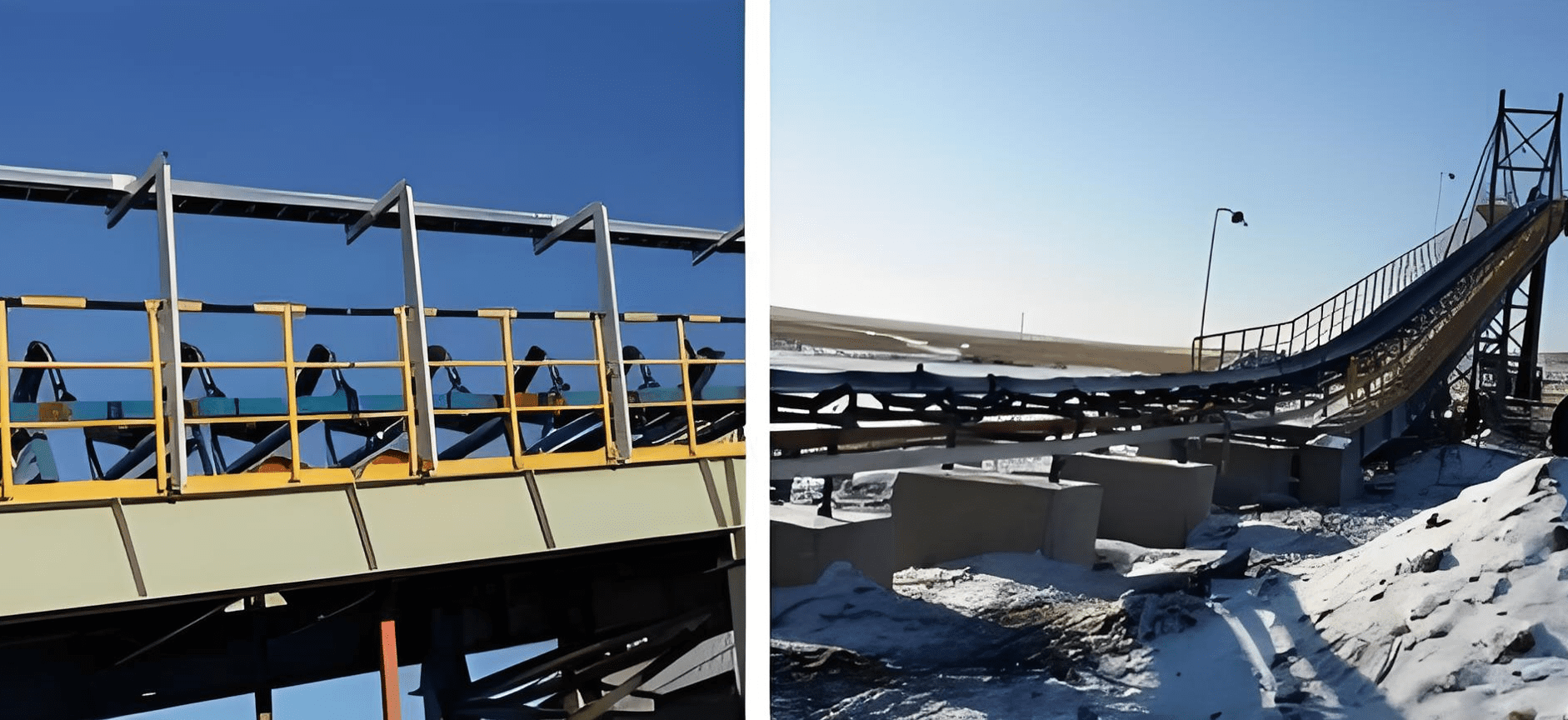

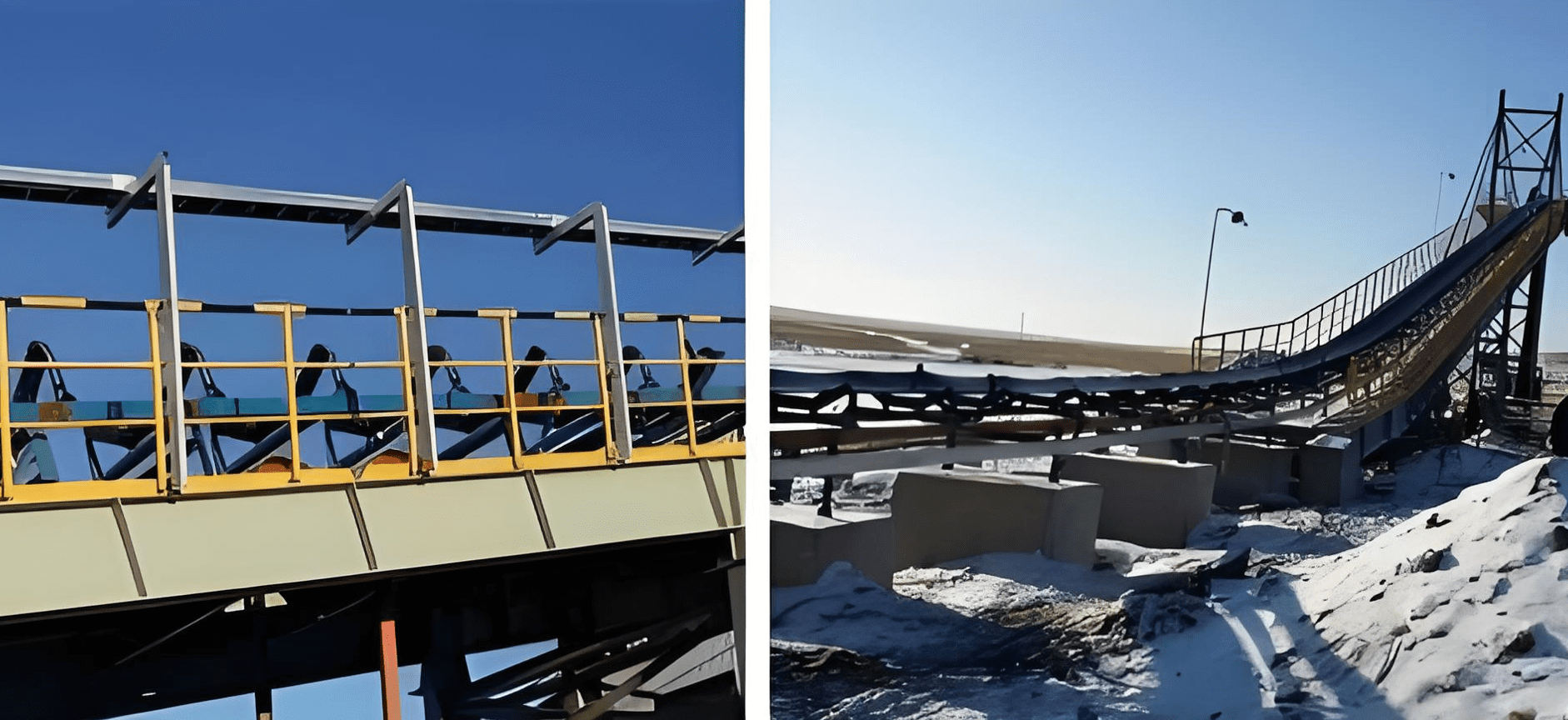

The DTII belt conveyor demonstrates its operational capability even in challenging weather conditions, as it traverses snowy areas. This adaptability highlights its durability and effectiveness in a variety of environments.

Project Overview:

- Company: Inner Mongolia Meifang Energy Co., Ltd.

- Production Capacity: 2×960,000 tons per year

- Belt Widths: 1.4m, 1.2m, 0.8m, 0.65m

- Total Length: 3,500m

DTII Belt conveyor Principle

The conveyor belts (or wire ropes) are connected into a closed ring, and they are tightened with a tensioning device. Driven by the motor, the friction between the conveyor belts (or wire ropes) and the driving rollers (or driving wheels) makes the conveyor belt move. The belt (or wire rope) runs continuously to achieve the purpose of transporting the cargo from the loading end to the unloading end.

Advantages of our belt conveyor

- Large Transmission Flow Rate: Capable of handling substantial volumes of material quickly.

- Very Low Energy Requirement: Designed to operate efficiently, reducing energy costs.

- Low Investment and Service Costs: Cost-effective design minimizes initial investment and ongoing maintenance expenses.

- Stable and Trouble-Free Transportation: Ensures reliable delivery of products without interruptions.

- User-Friendly Operation: Easy to operate, making it accessible for all personnel.

- Reduced Manpower and Higher Productivity: Streamlined processes lead to improved efficiency and reduced labor costs.

- Continuous Operation: Maintains a steady flow of materials, enhancing overall production capabilities.

By implementing the DTII belt conveyor system, Inner Mongolia Meifang Energy Co., Ltd. not only improves its material handling processes but also supports its commitment to operational excellence and sustainability in energy production.