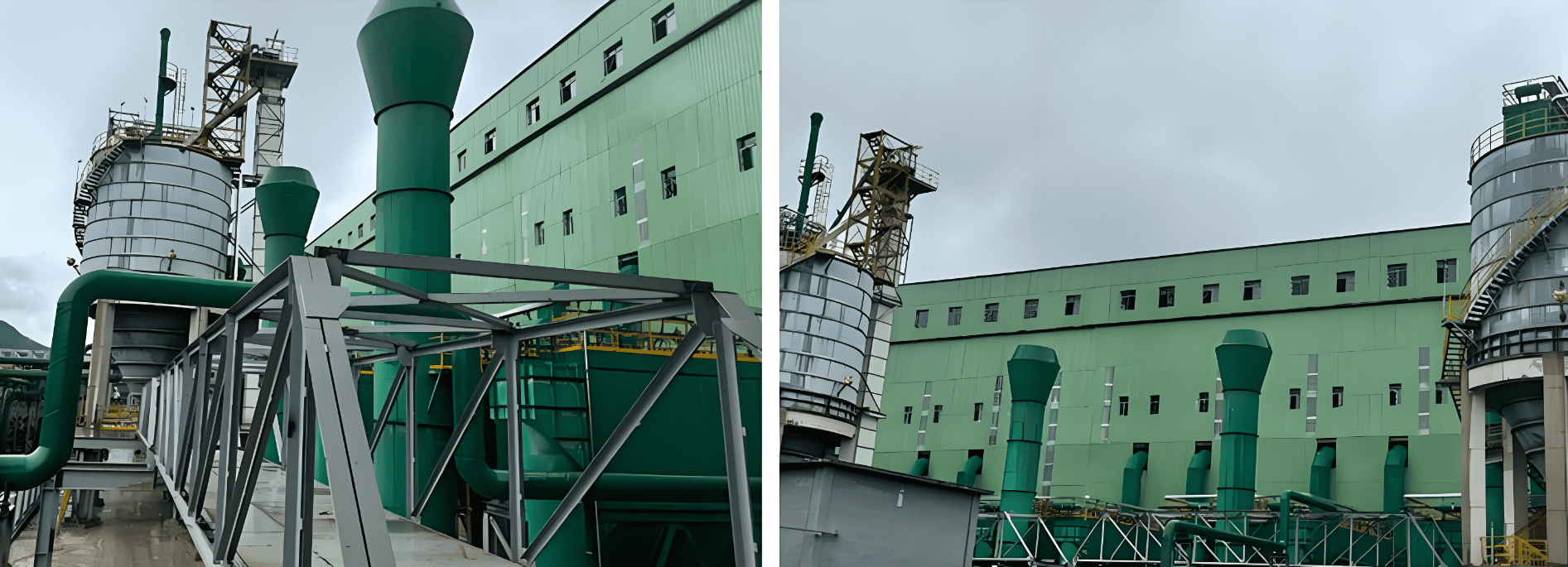

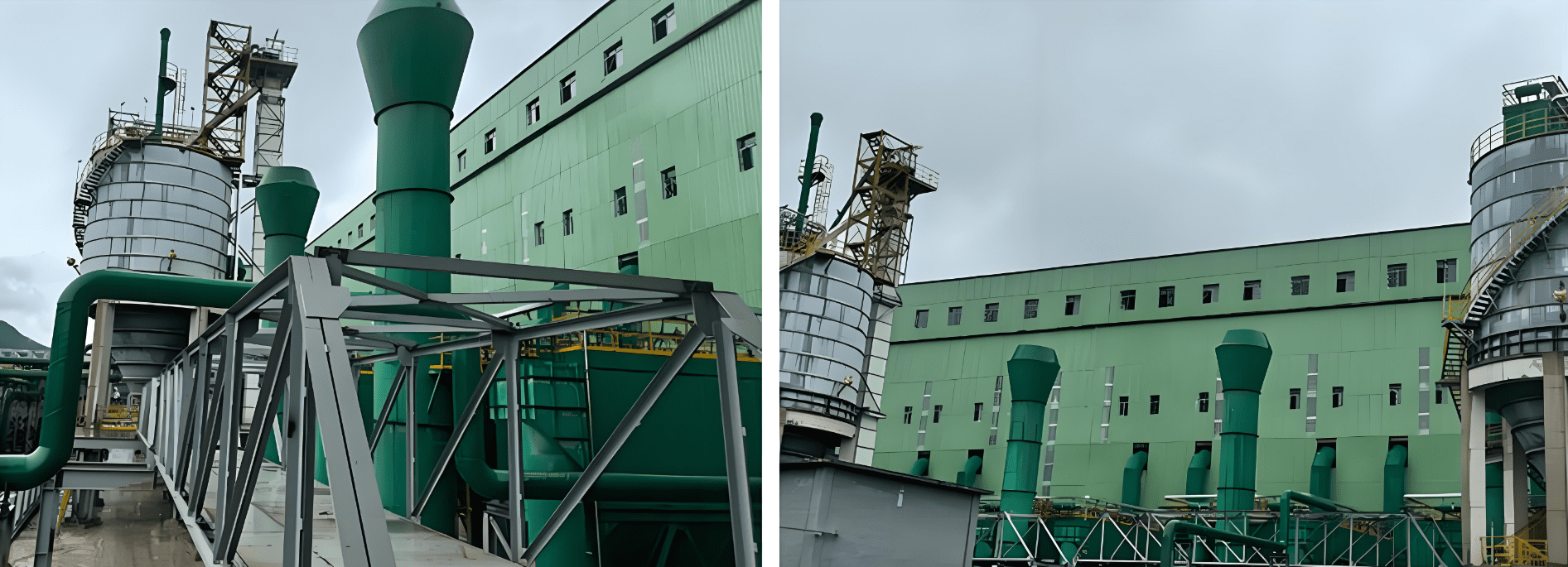

Baghouse Dust Collector project

Nantong Darko Building Materials Machinery won the bid for Huaxin’s dust collector equipment. This is for the 100 million tons machine-made sand and gravel project. This success demonstrates Nantong Darko's technical strength and competitiveness in the industry.

The Huaxin project is the world’s largest production base for machine-made sand and gravel.

Project Background

The Huaxin project is a large-scale construction material production initiative. It aims to meet the demand for high-quality machine-made sand and gravel through advanced processes and equipment. Huaxin decided to invest in high-efficiency dust collector equipment. This choice helps them comply with environmental regulations and improve efficiency. The equipment will reduce dust emissions during production and protect the environment.

Nantong Darko's bidding advantages

Technical Strength: Nantong Darko has extensive experience in designing and manufacturing dust collectors. Our products have a strong reputation in the industry. We use advanced filtering technology in our dust collectors. This technology ensures high efficiency, stability, and durability.

Customized Solutions: We provide tailored dust collector solutions to meet Huaxin’s specific needs. Our solutions ensure seamless integration with the production environment and process flow.

Comprehensive After-Sales Service: Nantong Darko offers full after-sales support. We assist with equipment installation, commissioning, and operation training. We also provide regular maintenance and technical help to ensure stable operation.

Project Achievements

Nantong Darko’s high-efficiency dust collector equipment reduced dust emissions in Huaxin’s project. It improved air quality in the production area. This achievement helped the project meet environmental standards. It also increased production efficiency and laid a strong foundation for sustainable development.