What is a big bag dust collector?

We refer to the big bag dust collector as the long-bag low-pressure pulse dust collector or the LCDM bag dust collector. It is, indeed, a new and efficient type of bag dust collector. It has been developed based on the conventional short-bag pulse dust collector. In addition, this series combines the advantages of various dust collection methods, including compartment fan backblowing and pulse blowing. Furthermore, we extend the length of the filter bags to fully utilize the powerful cleaning effect of compressed air.

Consequently, the LCDM baghouse system overcomes the drawbacks of low cleaning intensity in compartment backblowing. Moreover, it effectively addresses the issue of simultaneous dust filtration during pulse blowing. This, in turn, prevents ash from re-adsorbing and avoids out-of-control problems. As a result, the LCDM baghouse system not only improves filtration speed but also reduces cleaning energy consumption and prolongs the lifespan of the filter bags. Ultimately, we automate the entire LCDM baghouse system, using a programmable controller to efficiently manage the exhaust valve, pulse valve, and ash discharge valve.

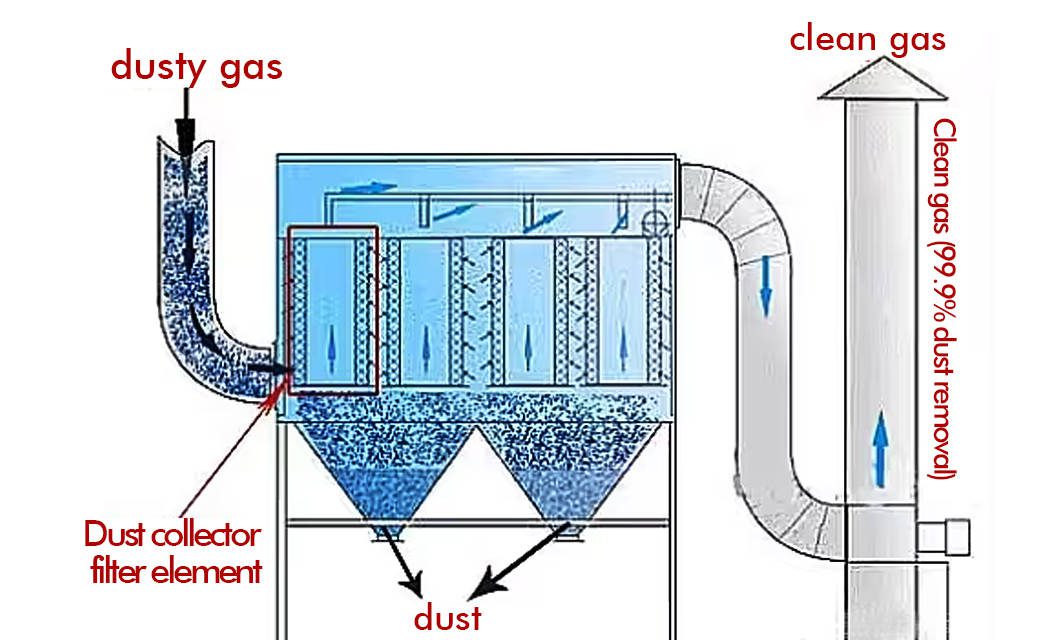

How does a big bag dust collector work ?

Ash-laden flue gas enters the channel from the inlet. It then bends down into the ash hopper. When the airflow hits the deflector, it turns into the bag chamber. Coarse particles fall to the bottom of the hopper due to inertia. Meanwhile, fine powder rises with the airflow. As the airflow passes through the filter bags, it retains the powder on the surface of the bags. The purified air gathers through the openings of the filter bags into the clean air box. It is then discharged through the exhaust butterfly valves of each chamber into the clean air duct.

The LCDM bag dust collector uses a compartment offline cleaning method. Several filter bags form a group in each chamber. As the filtration process continues, powder accumulates gradually on the outer surface of the filter bags. This accumulation causes an increase in the resistance of the LCDM bag dust collector. When the resistance reaches a certain range (1200–1500 Pa), the cleaning control system (PLC) sends a signal. First, the switching valve closes. Then, the pulse valve opens. Compressed air is injected through the nozzle into each filter bag. This causes the bags to deform and vibrate, effectively achieving the cleaning purpose.

After the cleaning process is completed, the switching butterfly valve opens again. The LCDM bag dust collector re-enters the filtration state. This design ensures that the processes do not interfere with each other. It allows for long-term continuous operation and improves cleaning efficiency.

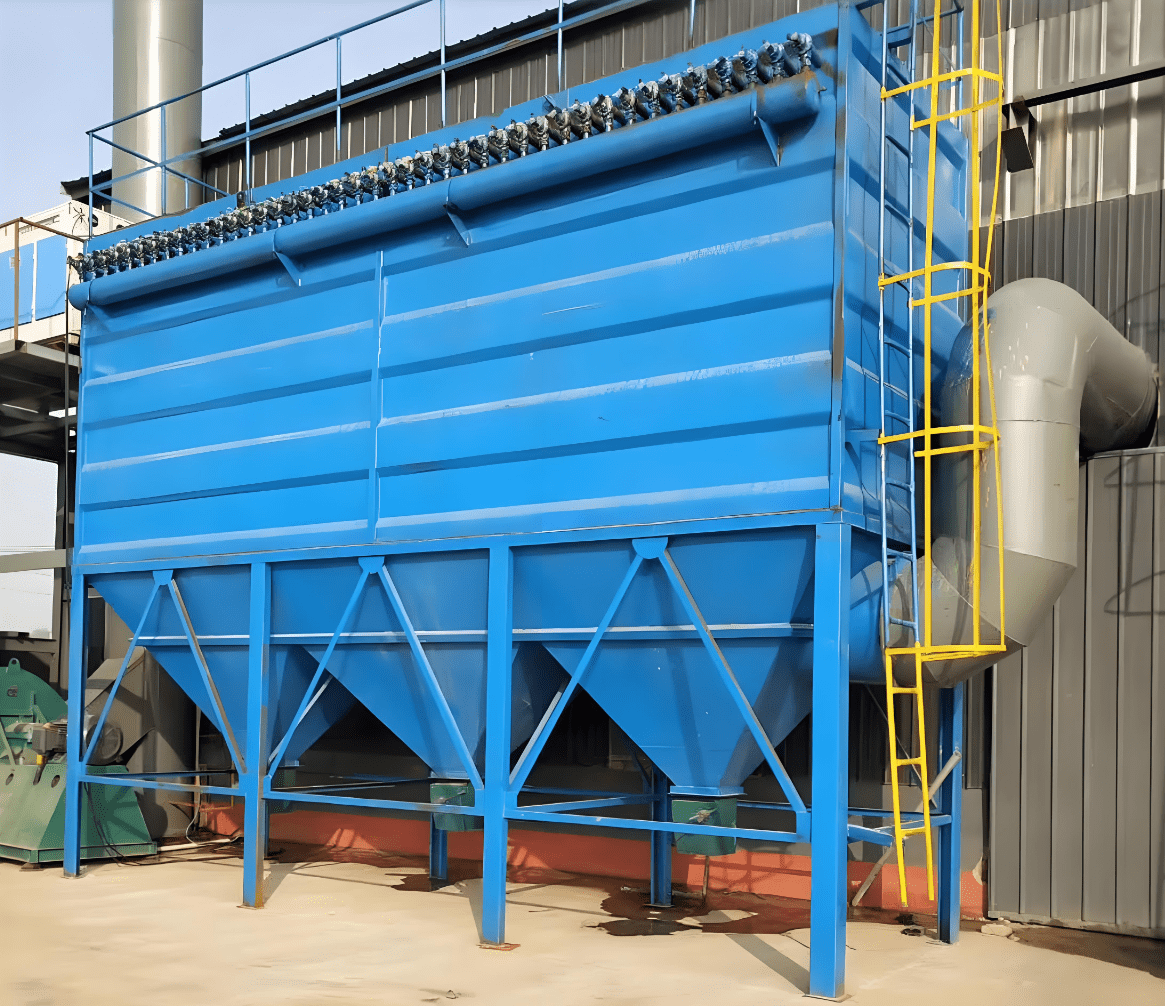

What is the typical structure of a LCDM bag dust collector?

(1) Filter Chamber

The filter chamber has a sealed structure, and each filter chamber is independent. A filter chamber is equipped with:

- Two access doors for inspecting and replacing filter bags.

- An inlet and an outletare respectively for connecting to the waste gas and the purified air.

- The chamber walls are using δ5mm steel plate, ensuring the LCDM bag dust collector can withstand pressures of ≤5000 Pa.

Inside the filter bag chamber, we weld a perforated plate to support the filter bags and bag cages. We shape this perforated plate using laser cutting, which ensures uniform hole diameters. This design guarantees a tight seal when we install the filter bags, preventing dust leakage and protecting the bags from damage. It allows for smooth installation or replacement of the filter bags and bag cages. We design the filter chamber as a fully welded structure, enabling the entire housing to withstand pressure and ensuring overall sealing integrity.

(2) Filter Bags

The main requirements for the material of filter bags in LCDM bag dust collectors are as follows. They should have good air permeability. They must exhibit low resistance. Additionally, high dust removal efficiency is essential. The filter bags should also have high tensile strength and a long service life. Furthermore, they need good resistance to high temperatures, acids, alkalis, oil, and water.

The top of the filter bag features a spring design made of stainless steel tape. This design provides good elasticity and resistance to corrosion. As a result, it ensures a long lifespan. The upper and lower parts of the filter bag are reinforced with additional fabric. This reinforcement enhances the strength of vulnerable areas, thereby extending the service life of the filter bags.

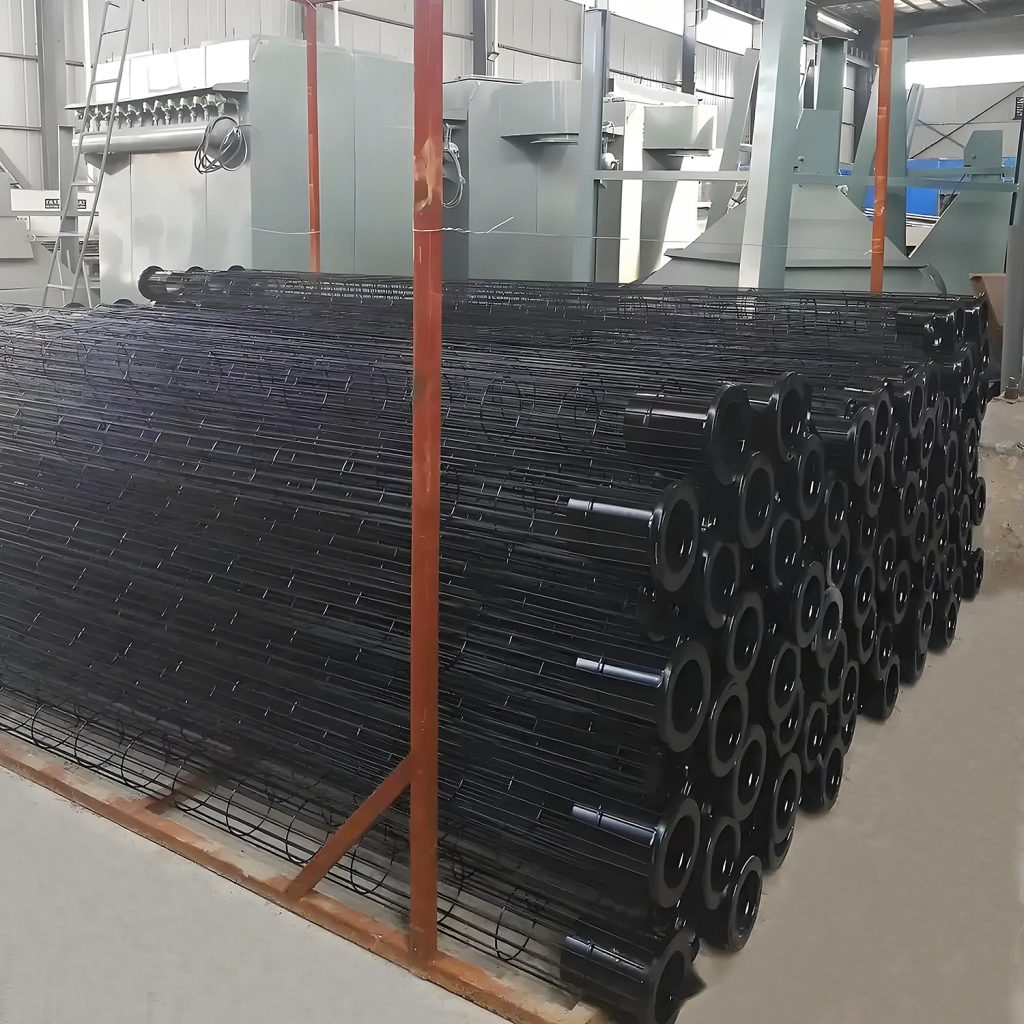

(3) Bag Cages

The bag cage is a key component of the LCDM bag dust collector, directly influencing the lifespan of the filter bags. To address this, Darko has implemented the following measures:

- We make the bag cages from cold-drawn galvanized steel wire, which provides good temperature and acid resistance. The surface is less prone to rust and the roughness that can result from corrosion.

- The upper connecting pipe of the bag cage fits tightly with the filter bag opening, ensuring concentricity. This will center the inlet air, which enhances the cleaning efficiency.

- The bottom of the bag cage features a conical design, making the installation or replacement of the bag cage very convenient.

- Darko produces bag cages on an automated production line. This process ensures one-piece formation, resulting in a smooth surface and high welding strength. The verticality of the bag cages is approximately doubled compared to national standards. This design ensures that the filter bags do not collide with each other. As a result, it extends their lifespan.

(4) Pulse jet Device

The pulse jet device is the heart of the LCDM bag dust collector and directly affects its performance. In our design, we have implemented the following measures:

Blow Pipe

- The blow pipe features a plug-in structure, making it easy to assemble and disassemble.

- The nozzle of the blow pipe is arc-shape, which reduces blowing resistance.

- The nozzles of the blow pipe can be adjusted according to airflow distribution, ensuring minimal airflow discrepancies at each nozzle.

- We have added nozzles to the spray holes of the blow pipe, which helps prevent the blowing airflow from dispersing.

Distribution Header

- The pulse valve is resistant to corrosion.

- The pulse valve and the spray pipe of the distribution header use an "O"-ring seal, facilitating quick and easy maintenance or replacement.

- We arrange the pulse valve at a 90° angle, minimizing the layout dimensions.

- The distribution header is made of seamless steel pipe and features an oval head, ensuring a design pressure of 0.7 Pa.

- There are a safety valve, pressure gauge, and discharge valve, ensuring safety and cleanliness.

Others

- A ball valve is between the distribution header and the blow pipe, allowing for the isolation of waste gas during a pulse valve maintenance. This feature ensures that there is no ash inside the distribution header.

- This LCDM bag dust collector uses an air pressure of 0.3 to 0.6 MPa as the cleaning source, employing low-pressure, high-volume cleaning technology to ensure the longevity of the filter bags.

(5) Explosion Protection Device

- We use an adjustable explosion safety valve. By adjusting it, we can set different pressure release values. When the internal working pressure of the LCDM bag dust collector reaches a certain level, the explosion valve automatically opens. After pressure relief, the safety valve can automatically reset, maintaining its original sealing effectiveness.

- Dust-proof plates prevent the accumulation of combustible and explosive ash on internal components. These proof plates are on beams, separating plates, and similar parts. The angles of these dust-proof plates are over 70°. Additionally, the angle of the hopper is greater than 70°. To prevent dust accumulation due to too small an angle between the walls of the two hoppers (valley angle), we weld sliding plates to adjacent side panels to increase the valley angle, thereby eliminating dust deposits.

- This device is specifically designed for handling high-concentration, combustible, and explosive dust.

(6) Insulation and Air Leakage Prevention

Considering the potential for condensation blockage due to improper operation and high dust humidity, our long-bag low-pressure pulse bag dust collector uses a double-layer insulation system (air + 100 mm rock wool board). This design ensures excellent insulation performance.

Technical Highlights

Large Airflow Capacity: The LCDM baghouse is suitable for various types of dust-laden flue gas, with a maximum handling capacity of up to 100x104 m3/h.

High Dust Collection Efficiency: For flue gas with a dust concentration of less than <50g/Nm3, the LCDM dust collection efficiency can reach between 99.5% and 99.9%.

Effective Ash Cleaning: The components of the blowing device have excellent aerodynamic characteristics. When the blowing pressure is between 0.2 and 0.25 MPa, A LCDM baghouse achieves good ash cleaning results. This is true for gas with high dust concentration. The LCDM baghouse is also effective for gas with high moisture content.

Compact Footprint: When the blowing pressure is between 0.2 and 0.25 MPa, the LCDM system achieves good ash cleaning results. It effectively cleans gas with high dust concentration and also works well for gas with high moisture content.

Advanced Control Technology: The LCDM electrical control system utilizes a sophisticated programmable controller. It offers four selectable functions: online cleaning, offline cleaning, differential pressure cleaning, and timed cleaning. It also includes pressure and temperature monitoring systems, along with manual control options. This ensures high reliability, long service life, and ease of on-site adjustments.

Convenient Operation and Maintenance: The LCDM filter bag opening uses an elastic expansion ring. This ring can be directly embedded in the flower plate. It ensures both sealing and ease of disassembly. This design reduces the physical strain on operators.

Service Advantages

Darko's engineering team has years of industry experience, providing professional technical consultation and support. Our goal is to offer the most suitable solutions based on our customers' specific needs. Additionally, we provide comprehensive after-sales support to ensure the normal operation of the equipment and customer satisfaction, helping clients maintain performance and extend service life.

Conclusion

By choosing Darko's Big Bag Dust Collector, you will acquire an efficient and reliable dust collection device that helps maintain a clean and safe working environment while enhancing production efficiency. For more information or technical consultation, please contact our sales team; we are here to serve you.