What is flue gas desulfuration?

Flue gas desulfuration/desulfurization/ desulphurization(FGD) refers to a technology for purifying boiler flue gas. Specifically, it removes nitrogen oxides and sulfur oxides (SO₂ and SO₃). Moreover, this desulphurization process targets not only flue gas but also other industrial waste gases.

Darko’s flue gas desulfuration dust collector design achieves over 99% SO₂ removal efficiency. Additionally, the desulphurization system availability exceeds 99.5%. The desulphurization system purifies flue gas through chemical reactions and physical absorption.

Darko takes pride in our role in providing engineering filtration solutions that help protect the environment.

How does a flue gas desulfurization dust collector work?

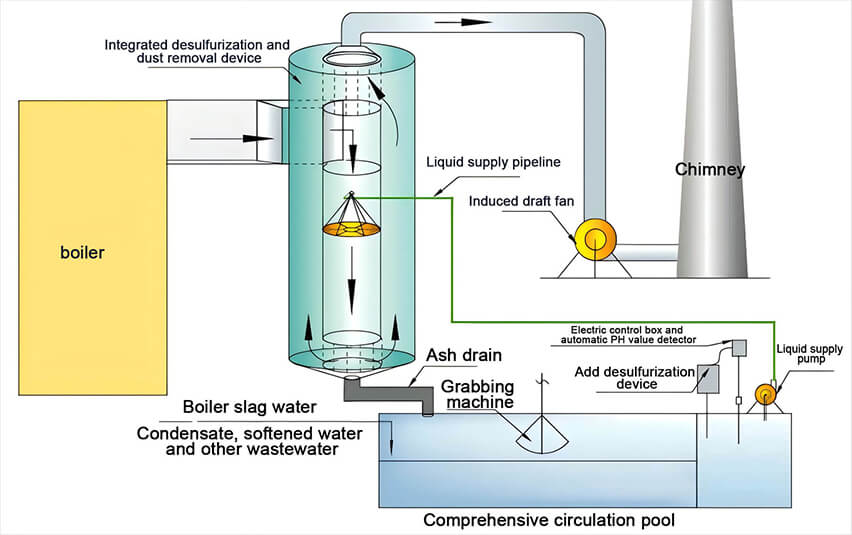

The wet high-efficiency flue gas desulfurization dust collector employs a pressure-based three-stage ash removal and desulfurization process. Specifically, it utilizes water (alkaline absorption liquid) as a medium. This method allows harmful substances, such as ash and SO₂, in the flue gas to make sufficient contact with the water in stages. As a result, this interaction forms an effective mist layer for collection and absorption. Through mass transfer reactions of solid, liquid, and gas, both ash and SO₂ are effectively removed from the flue gas.

The working principle involves the sulfur-containing and ash-laden gas first passing through a channel. Subsequently, it is sprayed out through nozzles. The alkaline liquid (such as lime) then forms droplets in the mist layer. Consequently, the ash particles in the flue gas collide violently with the atomized water. Under the impact of the water flow, a large amount of alkaline liquid splashes, thereby creating an effective gas washing and purification process. During this movement, the SO₂ in the ash-laden gas reacts with the alkaline substance. This reaction effectively neutralizes the SO₂ into neutral materials. Ultimately, both SO₂ and ash are captured. Finally, the purified gas is dehydrated to remove water mist before being discharged into the atmosphere through the chimney.

Features and benefits

High Dust Removal Efficiency

The desulfurization efficiency is improved by extending the length of the electric field. It commonly uses three electric fields. This achieves a capture desulfurization efficiency of over 99% when the ash in the flue gas is in a typical state. With the use of four or five electric fields, There will be a higher desulfurization efficiency in flue gas desulfurization system.

Low Operating Costs

- low resistance

- electricity consumption

- Single vibration mechanisms

- long lifespan

- minimal maintenance.

- long-term continuous and safe operation

Wide Applicability

Desulfurization dust collectors can capture particles smaller than 0.1 µm and purify high-temperature flue gas at 300-400°C. Wet flue gas desulfurization not only remove ash but also eliminate water mist and acid mist in the flue gas. They maintain good collection performance even when the flue gas undergoes certain changes.

Handling Large Volumes Gas

The desulfurization dust collector allows for easy modularization, enabling the scaling up of the system.

Compact Size and Lightweight

The desulfurization dust collector is a cylindrical body. Its moving and loading is very convenient. Based on the local conditions, the desulfurization can be hung from the left or right, or laid overhead.

Excellent Dewatering Effect

The flue gas desulfurization cylinder body has dewatering equipment. The dewatering plate is a common, well-designed type. When the mist passes through the equipment, it gets knocked down. This changes its direction, causing it to flow down the cylinder wall. This avoids re-wetting and ensures high dewatering efficiency.

Strong adaptability

Different flue gas desulfurization processes can adapt to various sulfur content levels in coal. Agents such as lime, alkali, and magnesium oxide can be used to achieve good flue gas desulfurization results.

Simple Operation

The operation is simple and convenient. It needs little maintenance. So, it is easy to manage. This results in a high operational rate.

Application fields

- Ash removal and desulfurization of coal-fired circulating fluidized bed boilers in power stations.

- Wet desulfurization and ash removal and flue gas purification of coal-fired chain boilers.

- Removal of hydrogen fluoride and acidic waste gas purification of furnace tail gas in the kiln industry.

- Pelletizing flue gas in steel plants.

Darko's flue gas desulfurization device is based on the theory of permeable surface renewal and the strong mass transfer mechanism of multiple turbulent mixing. It utilizes liquid as a separating agent to separate dust, flue gas, and harmful gases diffused in flue gas, air, or waste gas, achieving purification. This is a high-tech dust removal and desulfurization equipment.

Darko's flue gas desulfurization features include: integration of dust removal and desulfurization, low energy consumption, small footprint, simple operation, significant desulfurization efficiency, low operating costs, non-clogging and non-scaling, stable system operation, and low pressure loss. It can also use various sulfur-fixing agents.

In terms of wet dust removal and desulfurization technology, Darko's flue gas desulfurization devices are leading both domestically and internationally, achieving zero emissions in applications for coal-fired industrial boilers.

For more information or technical inquiries, please feel free to contact us. We are happy to assist you.