The rotary feeder for the vertical mill serves as a large-scale rotary air-locking feeding valve specifically designed for vertical mill feeding. It feeds raw materials to cement vertical mills and coal vertical mills.

This feeding valve features a good air-locking effect. Furthermore, it prevents blocking and material sticking while offering excellent wear resistance. Additionally, operators can flexibly adjust the rotor gap to optimize performance. In terms of maintenance, the wear-resistant scraper plate and lining cylinder can be replaced after wear, ensuring continued efficiency. Moreover, the entire valve body can be repaired and reused multiple times, which significantly contributes to its long service life.

Performance characteristics

1.The rotary feeder has simple structure, reliable performance and good sealing performance.

2. There are replaceable anti-wear lining and inspection door, and its structural characteristics can solve the problem that the grinding material is not stuck because of the particle size. It is prominent in the long-term use inside and outside.

3.The structure of the valve includes several key components, such as the rotary impeller, shell, and driving device. Notably, the rotary impeller is welded with wear-resistant plates, which significantly improve its service life.

In addition, the feed of the rotary discharger is designed with a certain deviation between the center distance of the mouth and the center line of the shell. This feature is particularly suitable for the entry of materials with large particles, allowing for efficient handling of various material sizes.

4. It typically equips the inner lining of the shell of the rotary valve with an anti-wear layer. The design supports the impeller with bearings at both ends, ensuring uniform clearance between the impeller and the shell. This design accommodates high feeding temperatures.

5. Both ends of the seal is sealed with asbestos disc, simple way, good sealing, easy to operate and replace.

Advantages

1. Effectively prevent materials from sticking, jamming, and blocking the equipment, improve the system operation rate, and reduce the impact of insufficient material supply on the firing system.

2. Significantly reduce the number of process shutdowns, increase the operating time of the raw material system, and reduce the increased power consumption due to system startup and shutdown.

3. Effectively reduce failure damage and operating wear, and reduce maintenance work and repair costs.

4. Good air locking can improve the external force and separation effect of fine powder inside the mill, thereby improving the mill system time.

Working principle

The rotary feeder is mainly composed of several key components:

- Shell: This is the outer casing that houses the internal mechanisms.

- Rotary Impeller: This rotating element helps transport materials efficiently.

- End Cover: It covers the ends of the feeder, providing structural integrity and protection.

- Sealing Pair: This component ensures that the feeder is airtight to prevent material loss during operation.

- Bearing: This part supports the rotating components, allowing for smooth and reliable operation.

- Transmission Device: It powers the rotation of the impeller, ensuring consistent performance.

Overall, the rotary feeder is designed for the quantitative feeding of powder and particle materials. Additionally, it utilizes gravity to facilitate the movement of materials, enhancing its efficiency in various applications.

Performance parameter

| Nominal Pressure | Proper Temperature | Applicable Media |

| 0.05MPa | ≤400℃ | Dry dust, particles, crystals, etc. |

Specification

| Models and specifications | Ability

(t/h) |

Power

(kw) |

D | H | A | B | C | Weight

(t) |

| EMV1200 | 220 | 9.2 | 1200 | 1600 | 1200 | 1400 | 1500 | 7.6 |

| EMV1600 | 320 | 11 | 1600 | 2200 | 1600 | 1800 | 3100 | 10.5 |

| EMV1800 | 550 | 15 | 1800 | 2500 | 1800 | 2000 | 3800 | 13 |

| EMV2000 | 600 | 18.5 | 2000 | 2800 | 2000 | 2200 | 4300 | 15.6 |

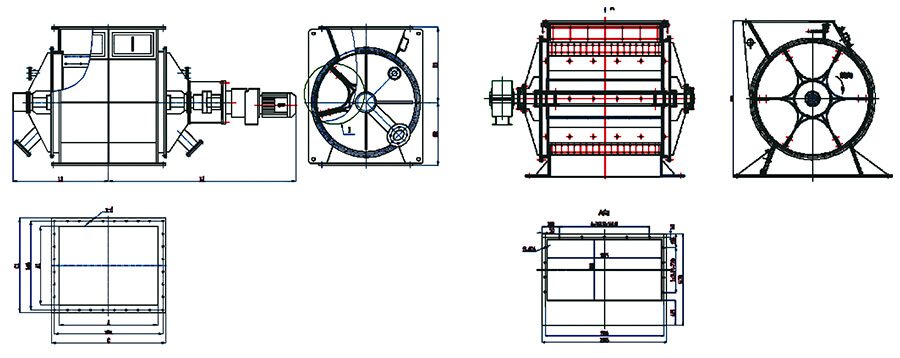

Diagram