What Is A Big Bag Dust Collector?

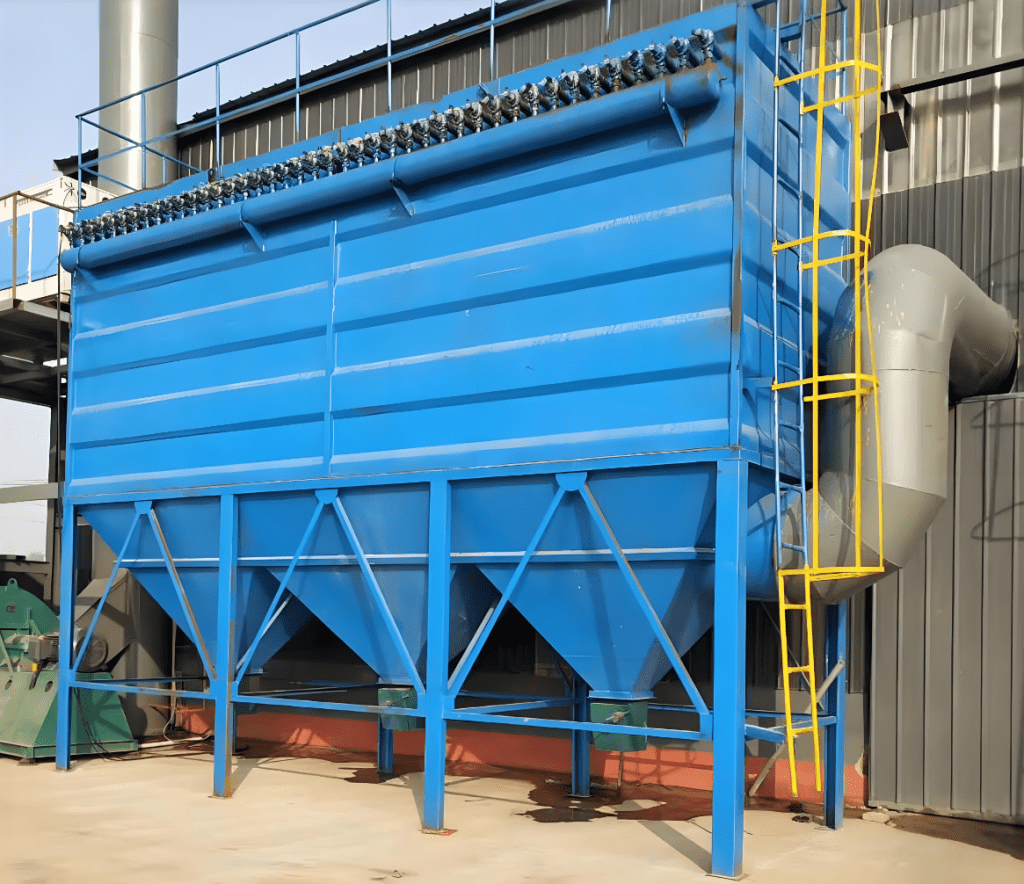

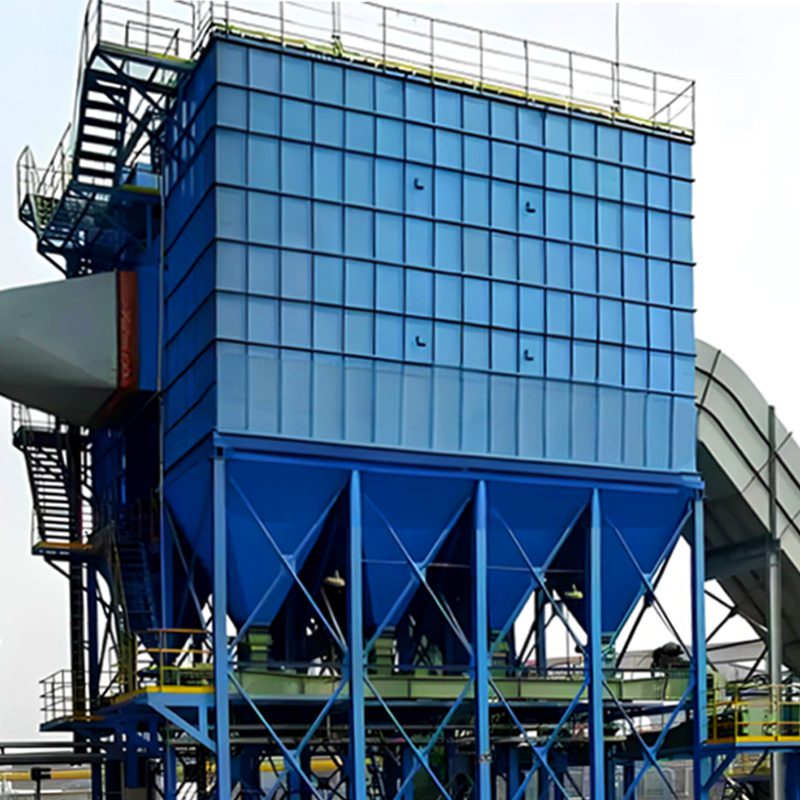

We refer to the big bag dust collector as the long-bag low-pressure pulse dust collector or the LCDM baghouse dust collector. The LCDM Long Bag Low-Pressure Pulse Jet Dust Collector is an advanced, high-efficiency baghouse system designed for large airflow applications. Developed as an upgrade to conventional short-bag pulse dust collectors, it integrates the best features of compartment backblowing and pulse-jet cleaning technologies. By extending filter bag length and optimizing compressed air usage, the LCDM system delivers superior dust removal, reduced energy consumption, and extended filter life—all controlled via an automated PLC system.

Key Advantages

High-Efficiency Cleaning – Combats dust re-adsorption with powerful pulse-jet technology.

Automated Operation – PLC-controlled valves (exhaust, pulse, discharge) for seamless performance.

Low Maintenance – External bag access and durable components minimize downtime.

Compact & Robust – Space-saving steel construction with high-pressure resistance (≤5000 Pa).

Working Principle

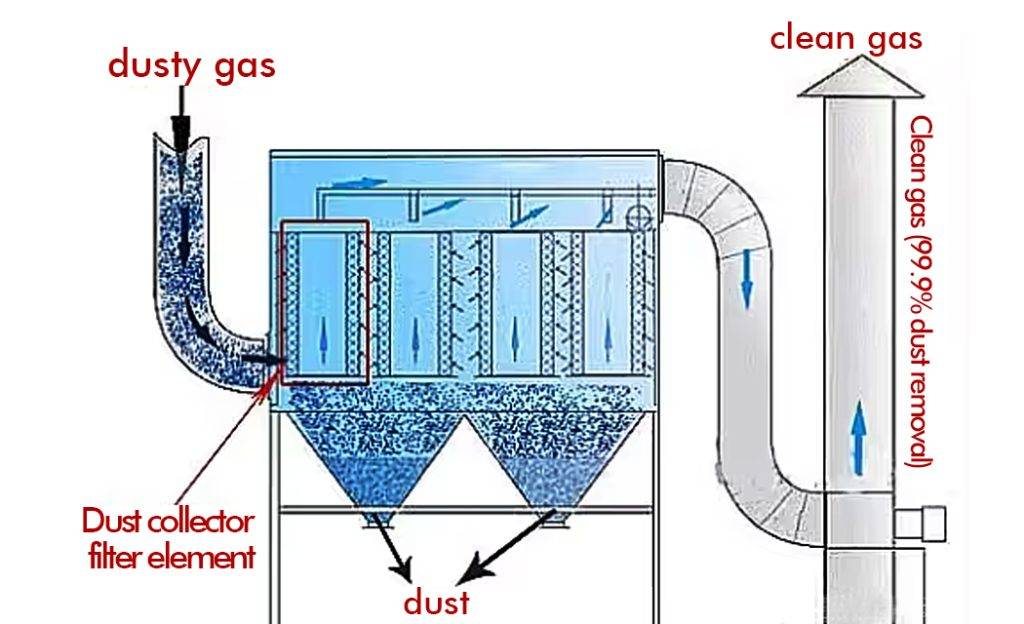

1. Filtration Process

Dust-laden gas enters through the inlet, where larger particles separate by inertia and fall into the hopper.

Remaining gas flows into the filter bag zone; dust collects on the bag surfaces while clean air passes through to the upper chamber and exits via the outlet.

2. Pulse-Jet Cleaning

When resistance reaches 1200–1500 Pa, the PLC triggers cleaning:

Switching valve closes → isolates the chamber.

Pulse valve opens → compressed air deforms bags, dislodging dust into the hopper.

Sequential chamber cleaning ensures uninterrupted filtration.

3. Dust Discharge

Collected dust falls into the hopper and is removed via slide valves or airlock discharge systems.

Structural Design

1. Filter Chamber

Sealed, pressure-resistant (δ5mm steel plate, ≤5000 Pa).

Laser-cut perforated plate ensures precise bag alignment and leak-proof sealing.

Access doors for easy bag inspection/replacement.

2. Filter Bags

Material: High-temperature, acid/alkali-resistant fabric with reinforced edges.

Stainless steel spring top ensures elasticity and corrosion resistance.

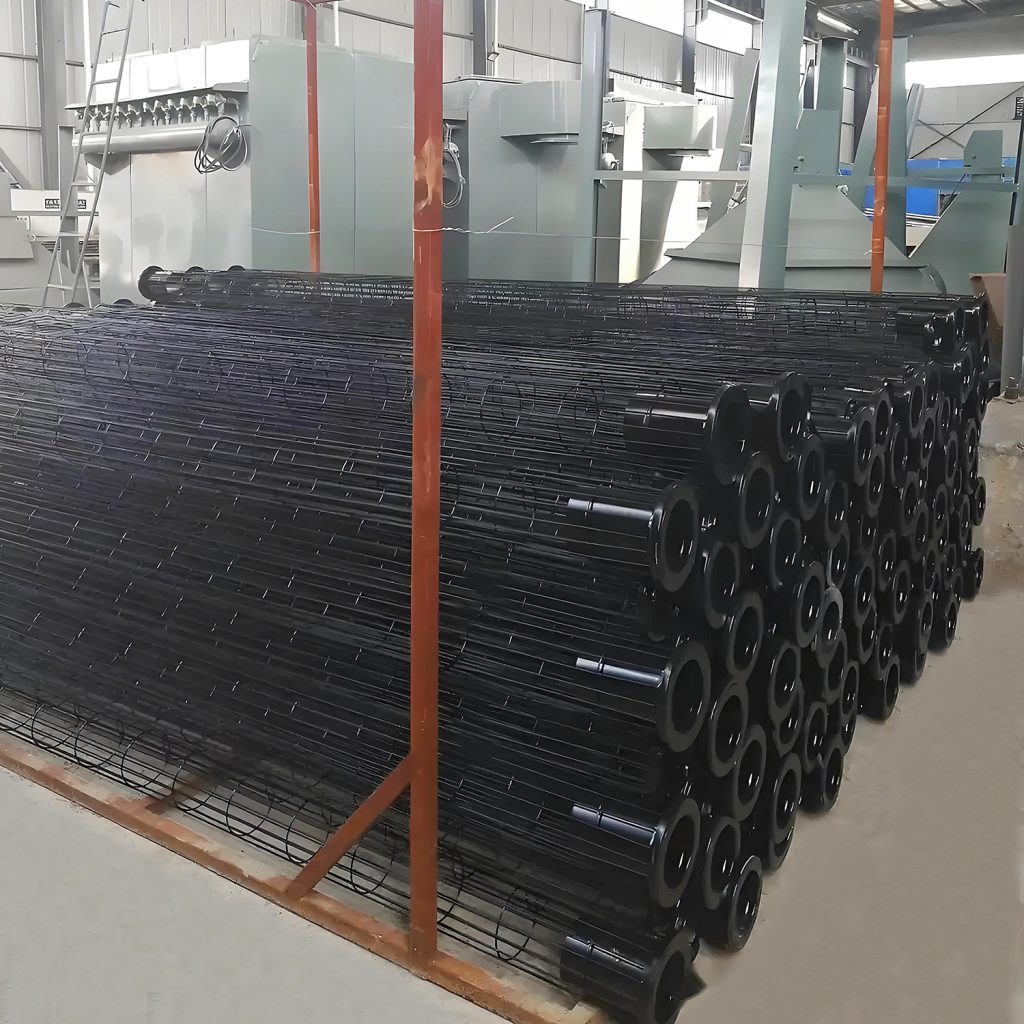

3. Bag Cages

Galvanized steel wire construction for durability.

Conical bottom design simplifies installation/replacement.

Automated production ensures smooth surfaces and <1% vertical deviation (exceeding national standards).

4. Pulse-Jet System

Arc-shaped nozzles minimize airflow resistance.

Modular blow pipes for easy maintenance.

0.3–0.6 MPa low-pressure cleaning extends bag life.

5. Safety Features

Explosion relief valves with auto-reset function.

Dust-proof plates (70°+ angles) prevent combustible dust accumulation.

Double-layer insulation (air + rock wool) prevents condensation.

Technical Highlights

| Feature | Specification |

|---|---|

| Max Airflow | Up to 1,000,000 m³/h |

| Efficiency | 99.5–99.9% (dust concentration <50g/Nm³) |

| Cleaning Pressure | 0.2–0.25 MPa |

| Control System | PLC (timed/differential pressure/offline modes) |

Why Choose Darko’s LCDM Dust Collector?

Expert engineering team – We design custom solutions for high-concentration and explosive dust.

Long-lasting durability – Our diaphragm valves last over 100,000 cycles and resist corrosion.

Complete service support – We provide installation guidance and ongoing technical support.

Darko’s engineering team has years of industry experience, providing professional technical consultation and support. Our goal is to offer the most suitable solutions based on our customers’ specific needs. Additionally, we provide comprehensive after-sales support to ensure the normal operation of the equipment and customer satisfaction, helping clients maintain performance and extend service life.Contact us today for a customized dust collection solution!

You may also like

|  |  |

|  |  |

Darko is among the fabric filters manufacturers in China. We have been supplying small and large companies with safe and ISO-certifed fabric filters wholesale. We provide industrial fabric filters of various specifications an custom sizes.

Darko has been working as a trust worthy fabric filter manufacturer and supplier in China for more than 10 years. With our years of experience in the industry, we can guarantee the production of high-quality Chinese fabric filters. Aside from manufacturing facilities in our own factory we also offer customization and design services to our customers. We produce fabric filters to process various air volume .

If you are looking for a filter company, you can rely on Darko. Buy fabric filters in bulk from us and let us help you grow your business using our customizable and affordable products