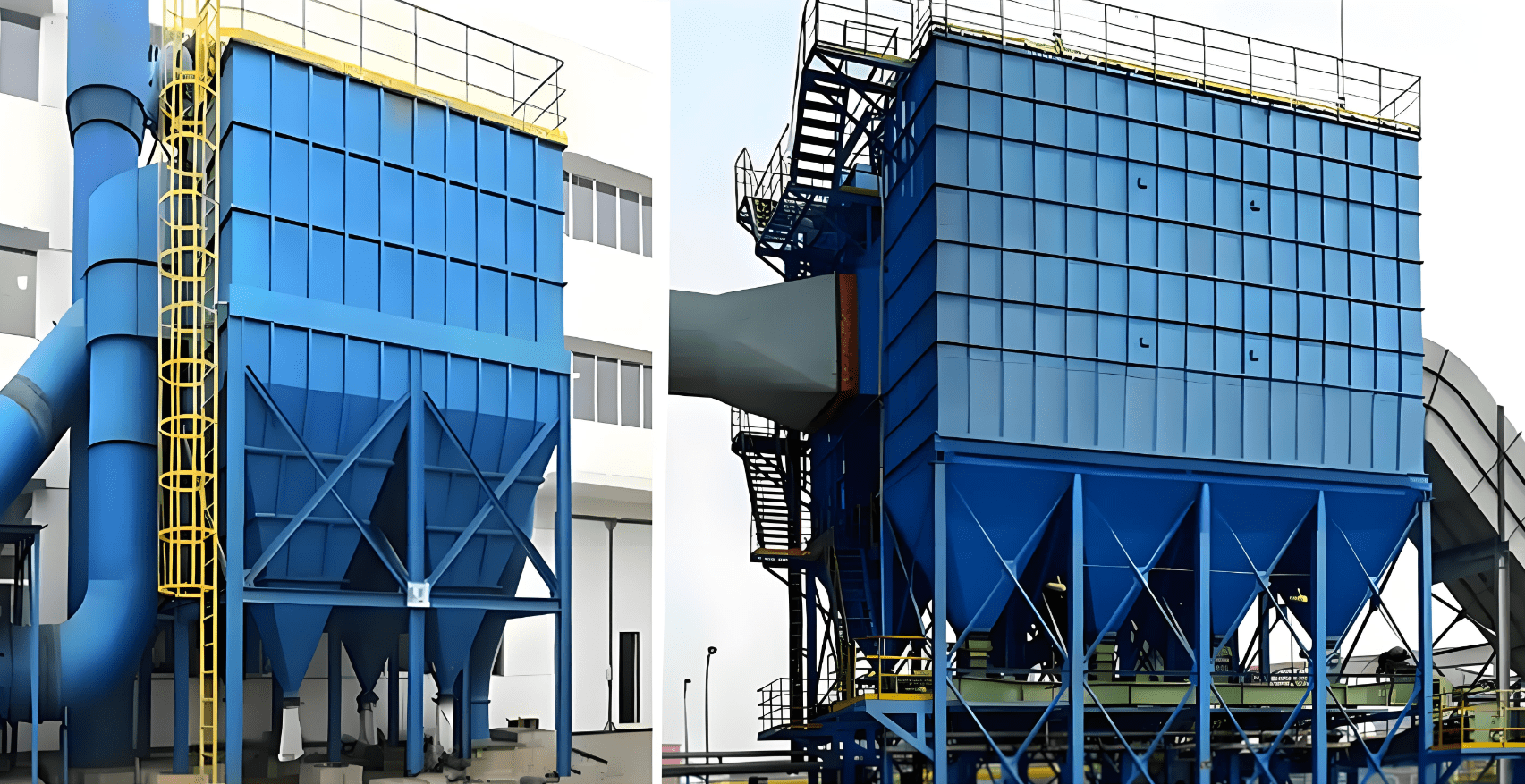

The boiler bag filter uses a dual-stage combined dust removal unit. This unit consists of a flame arrester and a bag dust collection system. It features high-performance PPS filter material for the filter bags. The flame arrester is installed before the bags. The system employs split-flow, smooth airflow technology. As a result, it offers reliable operation, high dust collection efficiency, easy operation, and compliant emissions.

Boilers generate steam for processing plants, power plants, and various other industries. They can use natural gas, electricity, oil, solid fuels, liquefied petroleum gas, or renewable energy to produce steam. Among these fuels, solid fuels are the cheapest, most polluting, and most widely used.

To control emissions from wood, coal, and lignite boilers, bag filters are essential. These pollution control systems limit the discharge of suspended particulate matter. If sulfur-containing gases are also a concern, a venturi wet scrubber should be combined with the boiler bag filter.

Darko manufactures high-quality boiler bag filters and supplies them globally. Our customer-centric approach makes us one of the most popular suppliers. As a reliable manufacturer, we provide high-quality bag filters for boilers.

Working principle of boiler bag filter

Dust-laden gas enters the unit through the inlet duct. The larger dust particles separate in the hopper and fall directly into it. The remaining dust flows with the gas into the filter chamber. Clean gas passes through the filter bags and is then discharged via the upper chamber, lift valve, and exhaust pipe. As filtration continues, dust accumulates on the surface of the filter bags. The dust cleaning control device follows a set program. It closes the lift valve and opens the electromagnetic pulse valve to shake off the dust from the bags. The dust falls into the hopper and is discharged through the ash discharge valve.

Application of Darko’s boiler bag filters

Darko boiler bag filters are widely used for dust control in cement plants and non-metallic mineral powder processing. They also show great promise in the power, chemical, metallurgy, and steel industries.

- Industrial and heating coal-fired boilers, heavy oil boilers.

- Dry and wet cement rotary kilns, vertical kilns, raw material and clinker mills.

- Sintering of copper, lead, and zinc, copper smelting furnaces, electric arc furnaces, and reflecting furnaces.

- Iron ore sinter machines (head and tail), blast furnaces, open hearth furnaces, coke ovens, converters, electric arc furnaces, and the refractory materials industry.

Components of the boiler bag filter System

The boiler bag dust collector consists :

- Housing:The housing includes the upper chamber (clean air chamber), middle chamber (filter chamber), lower chamber (hopper), flue gas distributor, perforated plate, platform, ladder, support legs, inlet, outlet, insulation layer, and color steel plates.

- Filter Bag Composition:The filter bag features a frame, fabric, and a self-locking design for easy installation and replacement. This design effectively extends the filter bag’s lifespan.

- Heat Distribution Device:The system uses upward airflow design for the flue gas distribution device. This design effectively distributes the dust-laden gas and separates larger particles, preventing abrasive impacts on the filter bags. This further enhances dust collection efficiency and extends the filter bag’s lifespan.

- Pulse jet system: During operation, the system typically performs pulse backwash cleaning every 10 seconds for each row of filter bags. The system activates the electromagnetic valve at a fixed time. Then it sprays pulse backwash compressed air into the filter bag for cleaning.

- The ash discharge system:It consists of an electric vibrator (air cannon), an electric heater, and an ash level indicator. The electric vibrator (air cannon) ensures that the dust has good fluidity.

- The control system:The system comprises several components. It includes a pulse jet controller and an MC computer control cabinet. It also features a thermal resistance thermometer, a static pressure measuring point, and a material level indicator. Additionally, it contains a measuring element.

- Offline protection system: There are sveral main components of the boiler filtration. These include a bypass valve, an emergency water spray system, and a differential pressure device. It also features a material level meter, a thermometer, and a pressure detection device. Additionally, the system includes a pulse controller and a filter bag leak detection device.

Technical features

① High temperature resistant filter material application technology:

The boiler bag filter system combines the characteristics of my country’s coal-fired boiler flue gas. It uses cost-effective, high-temperature, and corrosion-resistant boiler filter material. The fiber is treated with a PTFE membrane. This approach resolves the issue of high flue gas temperatures that ordinary filter materials cannot withstand. It also addresses the short service life of ordinary filter materials. Additionally, it considers the performance-price ratio of the filter material.

② Offline maintenance technology:

The application of new lifting valve technology enables the non-stop maintenance function of the bag filter. Users can select between offline and online cleaning methods at will. The protection device of the lifting valve eliminates failures caused by lifting valve issues. This ensures that the bag filter will not affect the operation of the boiler.

③Bag filter protection technology:

The use of online detection equipment addresses specific protection issues for the bag filter. This equipment includes an external bypass system and temperature and humidity measurement tools. It solves the protection problem when the boiler adds oil to assist combustion and during boiler failures.

④Detection and monitoring technology:

Based on the usage characteristics of the boiler bag dust collector, we established an online detection and monitoring system. This system includes monitoring flue gas temperature, humidity, collector operating pressure, material level detection, and equipment fault detection. It completes all functions such as measurement, monitoring, control, alarm, protection, and interlocking for the bag dust collector, enabling real-time monitoring of its operation.

⑤PLC Programmable Controller Technology

We utilize Siemens PLC products in our system. The PLC features a communication interface with the DCS, allowing for both manual and automatic control of the bag dust collector.

⑥Equipment Resistance Control

Darko ensures the safety and reliability of the overall resistance of the bag dust collector. We achieve this through a series of unique considerations in the equipment design. This assurance comes from two aspects: the equipment structure and the filter material.

The application of these advanced technologies makes our bag dust collectors technically mature and offers excellent cost-effectiveness.

You may also like

|  |  |

|  |  |

Darko is among the fabric filters manufacturers in China. We have been supplying small and large companies with safe and ISO-certifed fabric filters wholesale. We provide industrial fabric filters of various specifications an custom sizes.

Darko has been working as a trust worthy fabric filter manufacturer and supplier in China for more than 10 years. With our years of experience in the industry, we can guarantee the production of high-quality Chinese fabric filters. Aside from manufacturing facilities in our own factory we also offer customization and design services to our customers. We produce fabric filters to process various air volume .

If you are looking for a filter company, you can rely on Darko. Buy fabric filters in bulk from us and let us help you grow your business using our customizable and affordable products