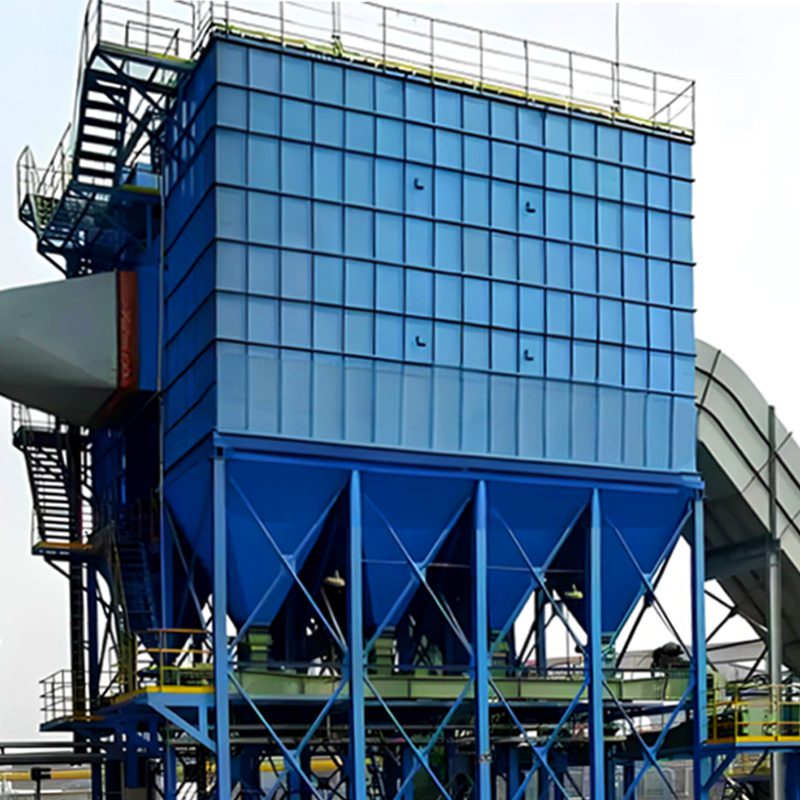

Overview of a cyclone dust collector

The cyclone dust collector or cyclone separator has been used since 1885. It has evolved into various forms. Depending on how the airflow enters, we can divcide cyclone into two categories. These are tangential entry and axial entry. Under the same pressure loss, the axial entry can handle approximately three times the gas volume of the tangential entry. It also provides a more uniform airflow distribution.

Working principle of a cyclone separator

- The cyclone separator uses the centrifugal force generated by the rotating airflow to separate ash particles from the airflow, and is used to separate particles with a particle size greater than 5-10μm.

- It has a history of more than 100 years in industry.

- Each component of the cyclone separator has a certain size ratio. Every change in the ratio relationship can affect the efficiency and pressure loss of the cyclone dust collectors. Among them, the cyclone diameter, air inlet size, and exhaust pipe diameter are the main influencing factors.

https://pin.it/1qd5rdlR5

A cyclone system composition

The cyclone dust collector is composed of an air inlet pipe, an exhaust pipe, a cylinder, a cone and an ash hopper.

Under normal operating conditions, the centrifugal force acting on the particles is 5 to 2500 times that of gravity, so the efficiency of the cyclone dust collector is significantly higher than that of the gravity settling chamber. Based on this principle, a cyclone with a dust control removal efficiency of more than 90% has been successfully developed. Among mechanical dust collectors, cyclone dust collectors are very efficient.

It is suitable for the removal of non-sticky and non-fibrous dust, mostly used to remove particles larger than 5μm. The parallel multi-tube cyclone device also has a dust control removal efficiency of 80-85% for particles of 3μm.

The cyclone dust collectors consist of special metal or ceramic materials that resist high temperatures, abrasion, and corrosion. And the cyclone system can operate at temperatures up to 1000°C and pressures up to 500×10^5 Pa.

Considering the technical and economic aspects, the pressure loss control range is generally 500-2000Pa. Therefore, it is classified as a medium-efficiency dust collector and can purify high-temperature flue gas.

Cyclone structural Features

①A straight-through side chamber effectively cleans the upper ash ring phenomenon and resists clogging.

②A cone structure resembling a straight cylinder cleans the formation of the lower ash ring. It avoids the rebound phenomenon of coarse ash particles in areas of local wear, thereby improving both the service life and dust control removal efficiency.

③The design of the cyclone device effectively prevents the secondary flying.

Technical specification

| Project | Model | Inlet air velocity m/s | Pressure loss | Dimensions(mm) | Weight(kg) | ||||

| 12 | 15 | 18 | X-Type | Y-Type | X-Type | Y-Type | |||

Processing traffic m³/h

| YX-5.5 | 1000 | 1200 | 1500 | 44-99 | 49-111 | Φ552×950 | 94 | 84 |

| YX-7.5 | 2000 | 2500 | 3000 | Φ762×1360 | 161 | 145 | |||

| YX-9.6 | 3000 | 3800 | 4500 | Φ996×1640 | 262 | 235 | |||

| YX-11 | 4000 | 5000 | 6000 | Φ111×1880 | 341 | 310 | |||

| YX-12 | 4900 | 6100 | 7300 | Φ1230×2090 | 416 | 376 | |||

| YX-13 | 5700 | 7100 | 8600 | Φ1330×2225 | 497 | 447 | |||

| YX-14 | 6700 | 8400 | 10100 | Φ1445×2420 | 568 | 512 | |||

| YX-15 | 8300 | 10400 | 12500 | Φ1599×2685 | 697 | 617 | |||

| YX-16 | 1000 | 12600 | 15200 | Φ1765×2950 | 840 | 765 | |||

| YX-17 | 11500 | 15200 | 17200 | Φ1890×3165 | 989 | 903 | |||

Cyclone application area

Cyclone dust collector has simple structure, low cost, easy installation and maintenance. It is mainly suitable for large ash particles, dry non-fibrous ash, and is suitable for smelting, casting, sandblasting, building materials, refractory and other industries. The cyclone separator has single-tube, double-tube and multi-tube combination forms according to the size of the air volume.

Darko offers different types of industrial cyclone dust collectors for various process requirements and environmental conditions. When selecting, it is essential to configure according to specific application needs.

1. By Structural Form

- Single cyclone separator: The most basic form, suitable for small-scale dust collection.

- Multi cyclone separator: Composed of multiple cyclone units, commonly used for large-scale dust collection, enhancing processing capacity.

2. By Airflow Direction

- Axial cyclone separator: Airflow moves along the axis of the cyclone, offering higher separation efficiency.

- Crossflow cyclone separator: Airflow enters at an angle to the axis of the cyclone, suitable for handling specific types of particles.

3. By Separation Efficiency

- High-Efficiency cyclone separator: Designed to capture fine particles, providing high separation efficiency.

- Low-Efficiency cyclone separator: Suitable for collecting larger particles, with lower separation efficiency.

4. By Inlet Method

- Side Inlet cyclone separator: Airflow enters from the side, suitable for specific process requirements.

- Top Inlet cyclone separator: Airflow enters from the top, commonly used in certain special applications.

5. By Application Area

- Cement industry cyclone separator: Specifically designed for cement production, handling cement dust.

- Metallurgical industry cyclone separator: Used in metal smelting and casting processes.

- Chemical industry cyclone separator: Suitable for dust collection in chemical reactions and pharmaceutical processes.

6. By Gas Type Handled

- High-Temperature cyclone separator: Capable of handling high-temperature gases, suitable for certain specialized industrial processes.

- Normal-Temperature cyclone separator: Used for processing gases at normal temperatures, with a wide range of applicability.

For more information or technical inquiries, please feel free to contact our sales team, and we will be happy to assist you.

You may also like

|  |  |

|  |  |

Darko is among the fabric filters manufacturers in China. We have been supplying small and large companies with safe and ISO-certifed fabric filters wholesale. We provide industrial fabric filters of various specifications an custom sizes.

Darko has been working as a trust worthy fabric filter manufacturer and supplier in China for more than 10 years. With our years of experience in the industry, we can guarantee the production of high-quality Chinese fabric filters. Aside from manufacturing facilities in our own factory we also offer customization and design services to our customers. We produce fabric filters to process various air volume .

If you are looking for a filter company, you can rely on Darko. Buy fabric filters in bulk from us and let us help you grow your business using our customizable and affordable products