What’s the double impeller feeder?

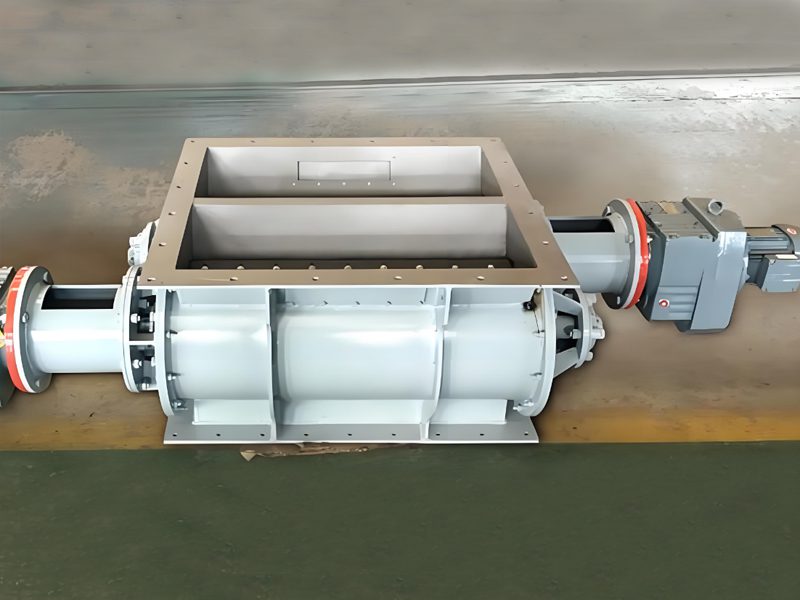

The double impeller feeder consists of several components. These include the feed inlet, dual-shaft parallel rigid impeller, discharge outlet, support frame, and flexible hose. Among these components, the dual-shaft parallel rigid impeller is the core part. The dual-shaft rigid impeller features six blades, which allow for adjustments in blade width and angle based on the material properties and conveying requirements.

Mechanism

The conveying mechanism of the dual-shaft rigid impeller feeder transports materials entering the feed inlet through the rotation of the impeller. The specific working principle is as follows: materials that enter the dual-shaft rigid impeller are acted upon by centrifugal force and gravity. This action causes the materials to rotate along the outer edge of the impeller. The fan-shaped chamber and conveying pipeline then drive the materials toward the discharge outlet, ultimately reaching the designated location.

Automation Control system

The dual-shaft rigid impeller feeder uses a PLC program for automatic control. This system achieves automation through the coordinated action of equipment such as motors, inverters, sensors, and pneumatic components. The PLC program can automatically adjust the impeller’s speed and direction, as well as control the opening and closing of the conveying pipeline. This effectively ensures the continuous and stable operation of the equipment during production and improves production efficiency.

Technical Highlight

High Efficiency and Stability

The design of the dual-channel impeller allows for uniform flow distribution, resulting in more efficient and stable flow output. This presents a clear advantage over single-channel impellers, which often suffer from unstable output and low efficiency.

Reduced Vibration and Noise

The dual-channel impeller can balance the excitation forces of the two flow branches, thereby alleviating vibration and noise issues. This is particularly advantageous in applications sensitive to vibration and noise, such as wind power generation, air conditioning, and heat exchangers.

Wide Adaptability

The design of the dual-channel impeller provides it with broad adaptability. It can accommodate various material flow states, demonstrating good performance across different application fields.

Applications

The dual-shaft rigid impeller feeder offers advantages such as high conveying capacity, long conveying distance, and fast conveying speed. It is widely used in industries such as chemicals, building materials, metallurgy, and food processing. Its effectiveness is particularly notable when conveying heavy and viscous materials that are prone to caking, especially those with significant variations in particle size.

By choosing Darko‘s double impeller feeder, you will gain exceptional performance and reliable operational support. Whether in the cement, mining, or chemical industries, this equipment provides stable solutions for your needs.

For more information or technical inquiries, please feel free to contact us. We are happy to assist you.