How’s a electric butterfly valve work?

The Electric Butterfly Valve from Darko offers exceptional control and reliability for your fluid handling needs. The electric butterfly valve uses an electric motor to drive the valve, controlling the flow of fluid media (such as gases or liquids) in pipelines.Its working principle is as follows:

Electric Motor Control

The electric butterfly valve has an electric motor that the electrical source powers and that a controller controls. Based on the required flow or pressure adjustment signals, the controller sends instructions to the motor.

Transmission Mechanism

The transmission mechanism connects the output shaft of the motor to the valve stem, transmitting torque and speed.The transmission mechanism can take the form of gears, belts, chains, etc., converting the motor’s rotational movement into the opening and closing motion of the valve.

Balancing Valve

The electric butterfly valve typically includes a balancing valve. This valve regulates the pressure of the fluid media. It prevents excessive pressure from damaging the valve.

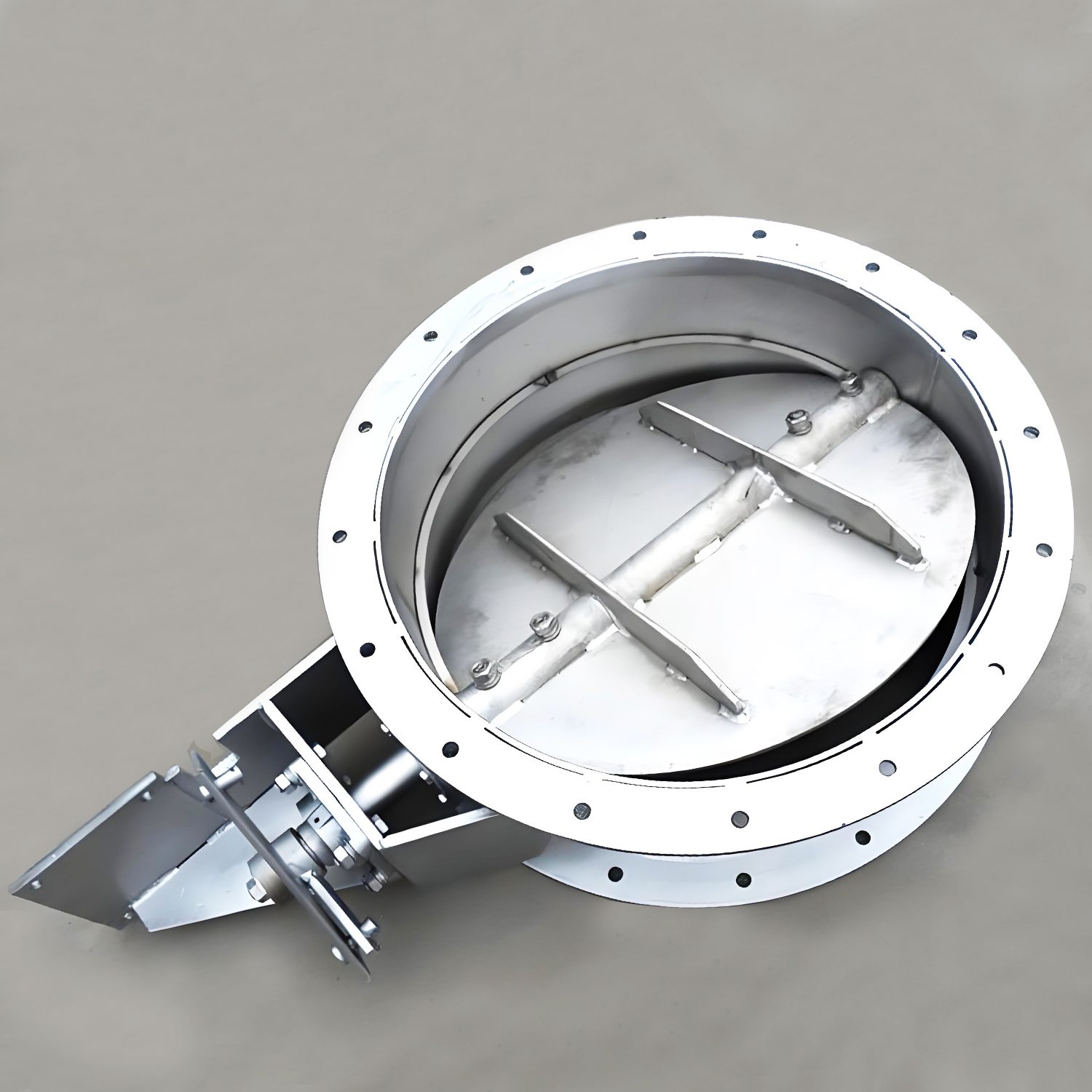

Valve Seat and Disc

Inside the electric butterfly valve, there is a valve seat and a valve disc. The valve disc opens or closes the valve through the rotation of the transmission mechanism. When the disc fits against the seat, it ensures the sealing of the fluid and prevents leakage.

Control Signals

The controller receives adjustment signals from external sources, such as pressure sensors or flow meters. Based on these signals, the controller adjusts the operating state of the motor to achieve the desired valve opening and flow.

Feedback Mechanism

e electric butterfly valve is often equipped with a feedback mechanism. This mechanism monitors the actual valve opening and relays this information to the controller. The controller can adjust based on the feedback information. This ensures the accuracy and stability of the valve’s operation.

Highlight

Strong Automatic Control Capability

The electric butterfly valve uses an electric actuator to control the opening and closing of the valve disc. This enables automation and facilitates centralized control and remote monitoring. As a result, it improves production efficiency.

Fast Response Speed

The electric actuator of the electric butterfly valve operates quickly. This allows for rapid adjustment of the valve opening. Such adjustments meet flow regulation requirements under different working conditions.

Simple and Convenient Operation

The use of an electric actuator for valve control makes operation simple and convenient. It eliminates the need for manual intervention. This saves labor costs.

Energy Saving and Emission Reduction

The electric butterfly valve can adjust the valve opening as needed for precise control. This adjustment reduces energy consumption and lowers emissions. It aligns with environmental protection requirements.

Low Maintenance Costs

The electric butterfly valve has a simple structure and fewer components. This design results in low maintenance costs and a long service life. These factors enhance the reliability and stability of the equipment.

Wide Applicability

It is suitable for various fluid media. It also has good sealing and corrosion resistance. These features make it widely applicable in fields such as chemical engineering, petroleum, and power generation.

Precise Control

The electric actuator can accurately control the valve opening based on the set control signals. This capability achieves precise flow regulation. Precise flow regulation is crucial for liquid and gas flow control.

Quick Response

The electric actuator’s fast response speed allows for rapid opening or closing of the valve. This capability enables quick response for flow control.

Multi-functionality

The control of the electric butterfly valve can be integrated with various automation systems. This integration allows for multi-functional control. For example, it can connect with sensors and controllers. This connection enables automatic adjustment and monitoring of parameters such as flow, pressure, and temperature.

High Reliability

Using an electric actuator to drive the valve reduces human error. It also decreases uncertainty. This improvement enhances the reliability and stability of the system.

Energy Saving and Environmental Protection

The valve can be adjusted in real-time according to system demands. This adjustment avoids energy waste caused by excessive opening or closing. Meanwhile, the electric actuator operates without producing pollutants or noise.

Remote Control

It can achieve remote control by connecting to a monitoring center. This connection can be made via a network or wireless communication. This enables remote monitoring and operation.

For more information or technical inquiries, please feel free to contact us. We are happy to assist you.