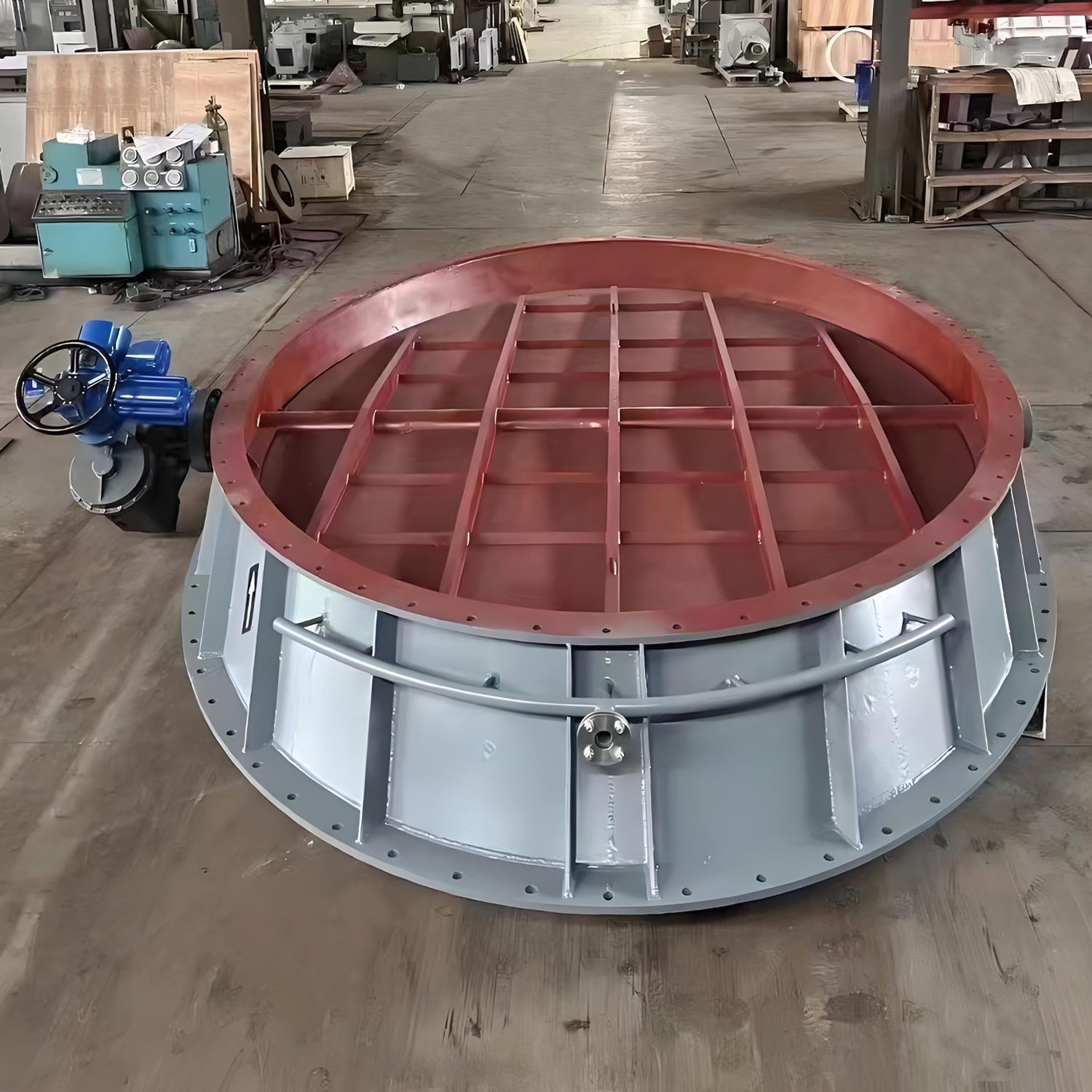

The irregular louver valve is a specialized type of valve that differs in structure and working principle from conventional valves. It typically features a movable inclined core structure, which adjusts the fluid’s on/off state by changing the angle of inclination, achieving control and regulation of flow and pressure.

Characteristics

Compared to ordinary valves, irregular louver valve have the following features:

1. Inclined Core: This allows for high flow rates with a small valve opening, reducing fluid velocity as it passes through the valve core, thereby avoiding excessive fluid resistance.

2. Self-Cleaning Function: This helps prevent issues such as clogging and leakage.

3. Dual Sealing Structure: Provides excellent sealing performance, preventing leakage problems.

4. Compact Size: The small and compact design allows for easy installation and maintenance.

Applications

The irregular valve damper louvers are widely used in the industrial sector, commonly found in pipeline systems, chemical industries, metallurgy, and more. Specific application scenarios include:

♦Flow Control

louver control valves can control flow rates, making them suitable for scenarios requiring flow regulation, such as in the water treatment industry where they are used to adjust water flow.

♦Pressure Control

By changing the angle of the valve core, louver control valves can control fluid pressure within pipelines, making them ideal for pressure regulation in industries like petrochemicals and chemicals.

♦Energy Conservation and Emission Reduction

With low flow resistance and minimal loss, louver control valves can effectively save energy and reduce emissions of waste gases, wastewater, and waste residues.

♦Other Applications

These valve damper louvers can also be used in thermal systems, air conditioning systems, and cooling water circulation systems.

Development Trends

With the continuous advancement of technology and progress in the industry, irregular louver valves are undergoing constant updates. The main development trends include:

1. Intelligence: Future louver valves will become more intelligent, featuring remote monitoring and control capabilities for more convenient operation and management.

2. Low-Temperature Operation: As energy utilization demands increase, valves will gradually adapt to low-temperature logistics and energy storage applications.

3. Energy Efficiency and Environmental Protection: The energy-saving and environmentally friendly characteristics of valves will receive more attention and application to meet energy conservation and emission reduction requirements.

4. Multifunctionality: Future louver control valves will be more multifunctional, not only controlling flow and pressure but also monitoring pipeline conditions and detecting water quality, thereby improving operational efficiency.

For more information or technical inquiries, please feel free to contact us. We are happy to assist you.

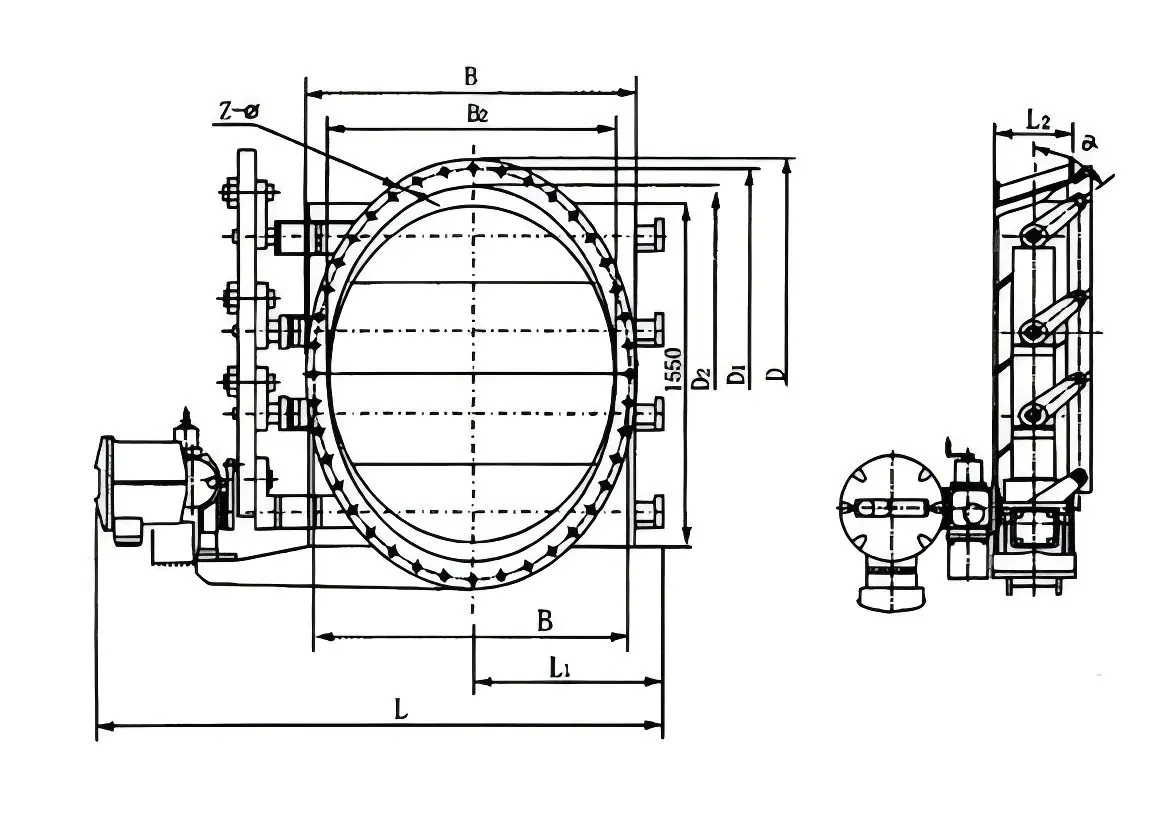

Installation drawing & dimensions

|

DN |

D |

D12 |

D2 |

B |

B1 |

B2 |

L |

L1 |

L2 |

Z- |

a |

|

1500 |

1990 |

1931 |

1831 |

1660 |

1600 |

1500 |

2450 |

935 |

340 |

42-22 |

55 |

|

1800 |

2377 |

2317 |

2197 |

1980 |

1921 |

1800 |

2800 |

1100 |

340 |

44-24 |

55 |

|

2000 |

2621 |

2561 |

2441 |

2180 |

2120 |

2000 |

2950 |

1200 |

400 |

44-24 |

55 |

|

2300 |

2987 |

2927 |

2807 |

2480 |

2420 |

2300 |

3510 |

1365 |

400 |

48-24 |

55 |