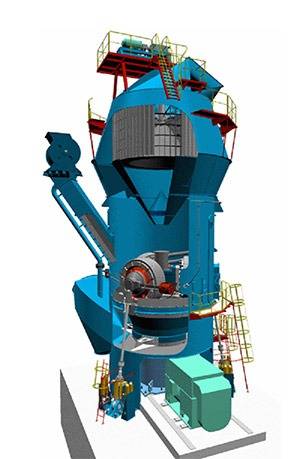

The advantages of the vertical roller mill include high grinding efficiency and low energy consumption. For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution due to its relatively low installation cost, ease of operation and maintenance, energy savings, and good product quality. Additionally, Darko cement grinding vertical mill solution can complete drying, grinding, and separation within a single unit.

The vertical roller mill consists of two parts: a roller mill and a powder separator. The main function of the roller mill is to grind materials, and the main function of the powder separator is to sort the ground materials.

Working principle

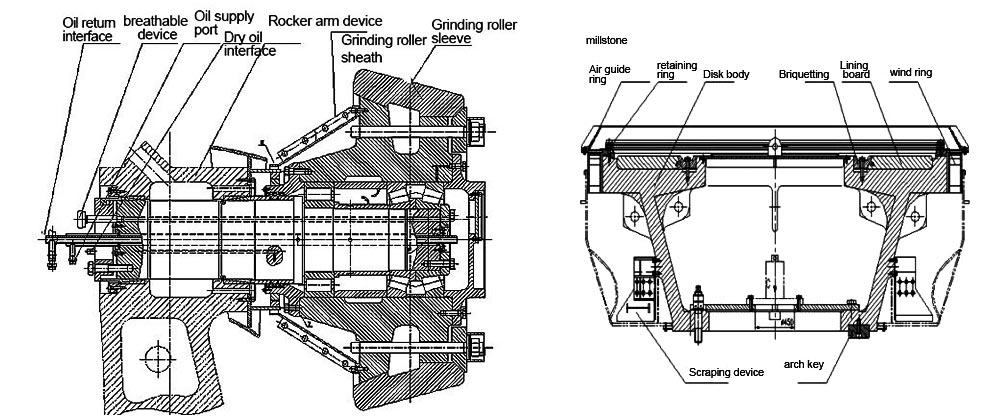

- The vertical roller mill powder separator operates as an airflow classification system. Mixed materials are discharged from the outlet and flow into the powder separator along with the carrier air. Fixed baffles between the upper and lower shells of the ash hopper convert the material/air mixture from upward flow to tangential flow.

- The internal grinding rollers roll on a rotating grinding table , creating a large swirling space between the fixed guide vanes and the rotor blades. Centrifugal force separates the material/air mixture in stages. Oversized particles are thrown out, sink due to gravity, exit the swirling space, and are collected in the ash hopper to be returned to the roller mill disc for further grinding.

- Finer particles pass through the rotating rotor blades and exit the powder separator with the carrier gas from the upper shell outlet. These particles are collected by the external powder selection dust collector before entering the next processing stage. The fineness of the finished product depends on the combined effects of the guide plate and the rotor speed. While the guide plate remains fixed, adjusting the rotor speed allows for control of the finished product’s fineness.

- Increasing the rotor speed results in finer products, while decreasing it produces coarser ones. A variable frequency motor, installed in the upper housing’s drive section, adjusts the rotor speed. By changing the current frequency, we can effectively control the fineness of the finished product. The ash hopper shell at the rotor’s base creates a space for the internal circulation of coarse particles, forming an orderly channel. This design separates the rising material/air mixture from the descending coarse particles, preventing their mixing and improving efficiency. Additionally, it directs unqualified coarse particles back to the vertical mill disc for secondary grinding.

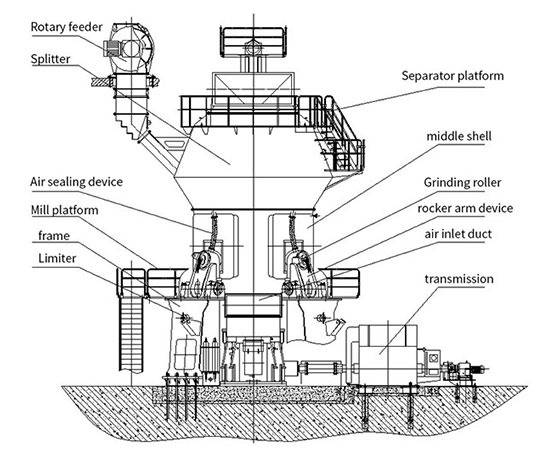

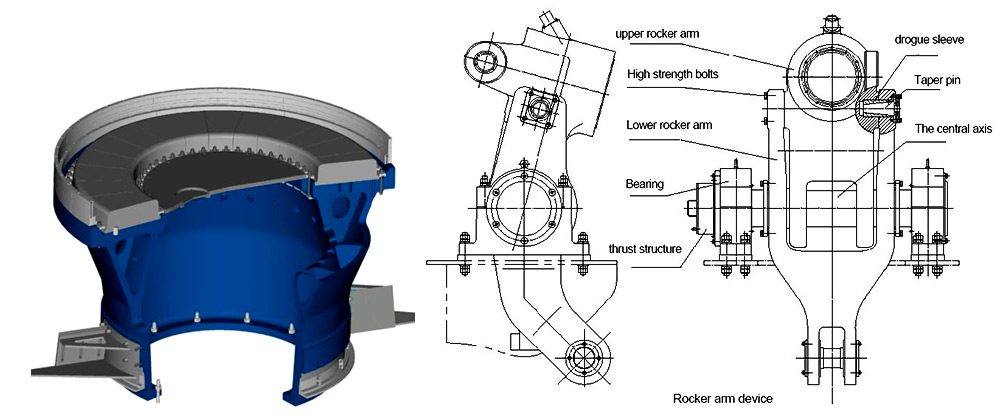

Main components of vertical roller mill

1.grinding roller;

1.grinding roller;

2.Middle shell;

3.air inlet duct

4.dry oil lubrication device;

5.limit device;

6.disk device;

7.rocker arm device;

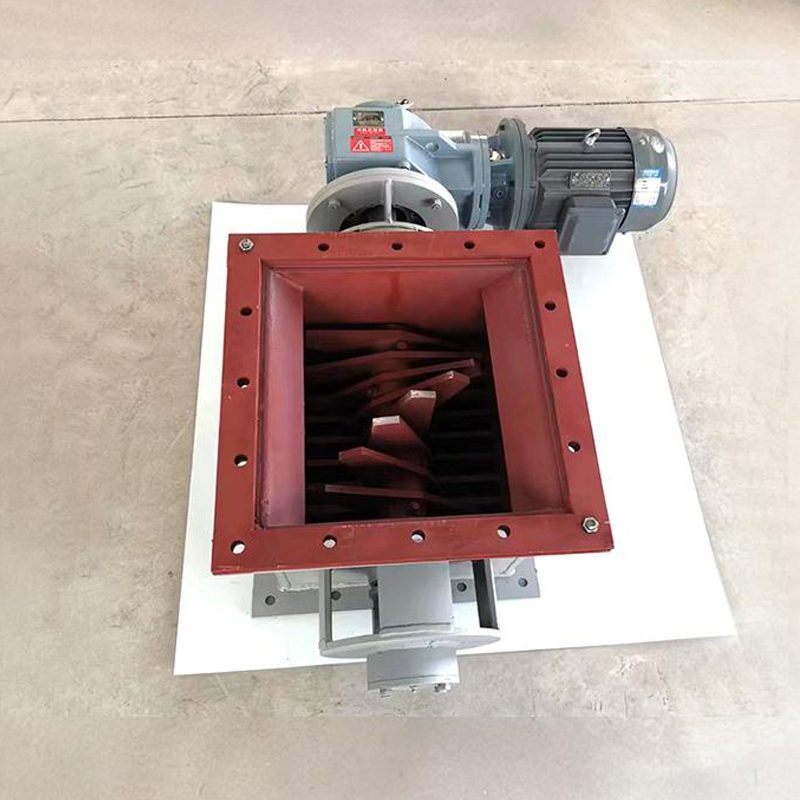

8.Splitter;

9.transmission;

10.sprinkler device;

11.frame;

12.Roller device;

13.Grinding roller pressure device;

14.Composed of air sealing device and other components;

15.Grinding roller lubrication device.

Characteristics of vertical roller Mill

♦The vertical roller mill can dry and grind materials with moisture content up to 10% simultaneously.

♦The process of a vertical roller mill is simple, with a compact structure that requires less building space. It occupies 70% of the floor space of a cement ball mill and 60% of the building space of a cement ball mill system. The vertical roller mill itself is equipped with a classifier, eliminating the need for separate classification and lifting equipment. The dust-laden gas generated during grinding can be collected using a bag filter .

♦The vertical mill uses the principle of material layering for grinding. It has low energy consumption, with powder consumption 20%-30% lower than that of a ball mill. As the moisture content of the raw materials increases, the powder consumption decreases significantly. The vertical mill is 30%-40% more energy-efficient than the ball mill. Additionally, the noise level of the vertical mill is lower than that of the ball mill, approximately 20-25 dB. The vertical mill operates in a fully enclosed system under negative pressure, resulting in no dust and a clean environment.

♦It uses a fully automated control system for remote control, making operations simple. Maintenance of the oil cylinder, rotation of the swing arm, and replacement of roller shells and liners are more convenient, reducing downtime losses.

♦The chemical composition is stable, and the particle distribution is uniform, which is beneficial for calcination. Generally, the retention time of raw materials in the vertical mill is 2-3 minutes, while in the ball mill, it can reach 15-20 minutes. The chemical composition and fineness of the cement in the vertical mill can be quickly measured and adjusted.

♦The grinding roller does not directly contact the grinding plate, resulting in minimal wear. The metal consumption per unit product is typically 5-10 g/t.

Specifications of vertical roller mill

| Model | Capacity(t/h) | fineness | Raw material moisture | Finished moisture | motor power (kw) |

|

HLM1300K |

10-40 |

0.84-0.37mm (20-400mesh) | ≤15% | ≤1% |

200 |

|

HLM1500K |

13-50 |

280 |

|||

|

HLM1700K |

18-70 |

400 |

|||

|

HLM1900K |

20-85 |

500 |

|||

|

HLM2200K |

35-135 |

800-900 |

|||

|

HLM2400K |

40-160 |

900-1120 |

|||

|

HLM2800K |

50-200 |

1120-1250 |

|||

|

HLM3400K |

70-260 |

1800-2000 |

|||

|

HLM3700K |

90-320 |

2500-2800 |

The supporting equipments of vertical roller mill

Darko has been providing vertical roller mills (VRM) for the grinding of raw materials, coal, slag, and cement. The vertical roller mill is a well-known preferred grinding machine in the cement and power plant industries. Darko’s experts leverage our technological development capabilities. Additionally, we will utilize our core manufacturing expertise. Furthermore, we maintain strict quality control measures and provide exceptional customer service. As a result, our goal is to assist global clients in developing reliable, energy-efficient, and high-performance vertical roller mill grinding solutions.