Grelhas e válvulas de borboleta são normalmente utilizados em condutas industriais. Regulam principalmente o caudal e a pressão dos fluidos para garantir processos industriais sem problemas. Embora ambos desempenhem funções semelhantes, diferem significativamente em termos de estrutura, princípios de funcionamento e áreas de aplicação.

Diferenças estruturais

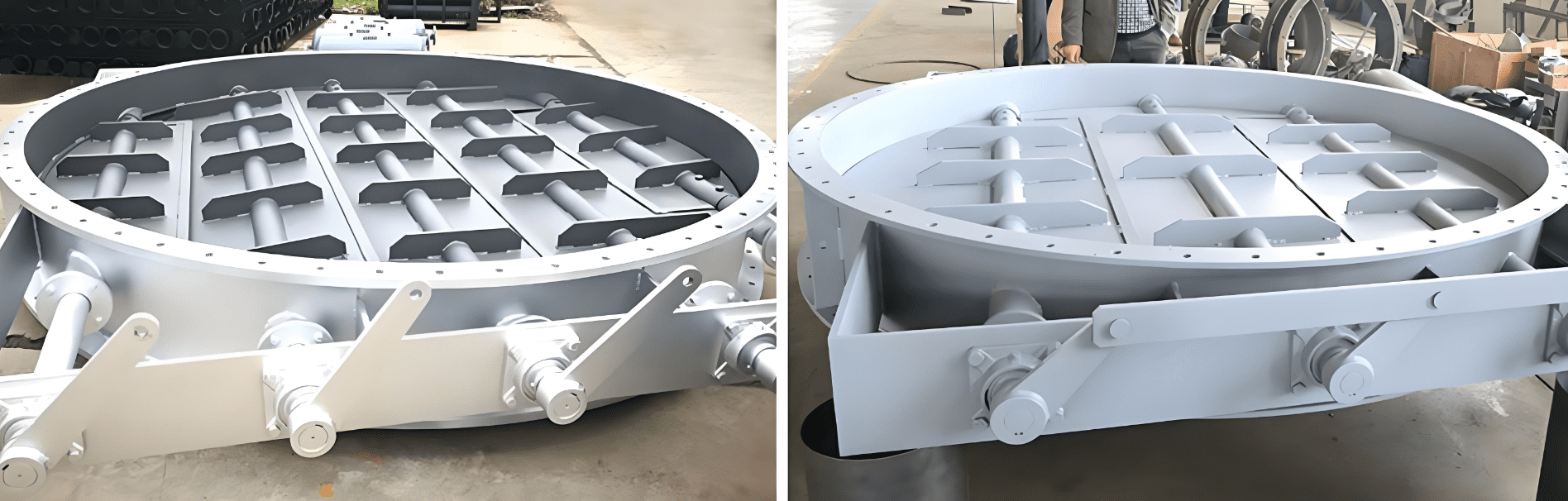

Válvulas de persiana

As grelhas assemelham-se a um amortecedor e são constituídas por várias camadas de lâminas ajustáveis. Ao rodarem as lâminas, controlam eficazmente o fluxo do meio. O seu design complexo proporciona uma forte vedação, tornando-as adequadas para líquidos de alta viscosidade e lamas.

Válvulas de borboleta

As válvulas de borboleta utilizam um disco rotativo central para controlar o fluxo de fluido. O disco assemelha-se a asas de borboleta e alterna entre as posições aberta e fechada. A sua estrutura simples permite uma operação fácil, mas têm capacidades de vedação inferiores, o que as torna mais adequadas para meios de baixa viscosidade.

Áreas de aplicação

Válvulas de persiana

As grelhas são muito utilizadas em sectores como o petróleo, os produtos químicos e o tratamento de águas residuais. São excelentes na regulação e corte de líquidos de alta viscosidade e lamas. Nestes sectores, as grelhas proporcionam um controlo preciso do fluxo, garantindo a estabilidade do sistema.

Válvulas de borboleta

As válvulas de borboleta são adequadas para água, gás e vapor, normalmente utilizadas em sistemas de drenagem e AVAC. O seu design simples e o baixo custo tornam-nas populares em muitas aplicações.

Comparação de desempenho

Vedação

As grelhas oferecem uma vedação superior devido ao seu design de lâminas em camadas, impedindo eficazmente as fugas. Para aplicações que exigem um elevado desempenho de vedação, as grelhas são a melhor escolha.

Estabilidade

As válvulas de borboleta proporcionam uma melhor estabilidade durante o ajuste do caudal. Permitem respostas rápidas, o que as torna ideais para aplicações que necessitem de comutação rápida.

Materiais

As grelhas utilizam normalmente materiais como o aço fundido e as ligas à base de níquel para lidar com meios corrosivos e de elevada viscosidade. As válvulas de borboleta utilizam frequentemente ferro dúctil e aço inoxidável, o que permite aplicações mais vastas e uma maior tolerância à pressão.

Conclusão

Em resumo, as grelhas e as válvulas de borboleta têm as suas vantagens e desvantagens. A escolha entre elas depende das condições de trabalho específicas e das caraterísticas do meio. Para o manuseamento de líquidos de alta viscosidade e lamas, as grelhas oferecem uma excelente vedação e controlo do fluxo. Para meios de baixa viscosidade, a estrutura simples e a facilidade de funcionamento das válvulas de borboleta tornam-nas preferíveis. Compreender estas diferenças ajuda a fazer escolhas informadas, melhorando a eficiência e a segurança nos processos industriais. contactar-nos.

> Melhorar a vida útil da válvula de descarga Star