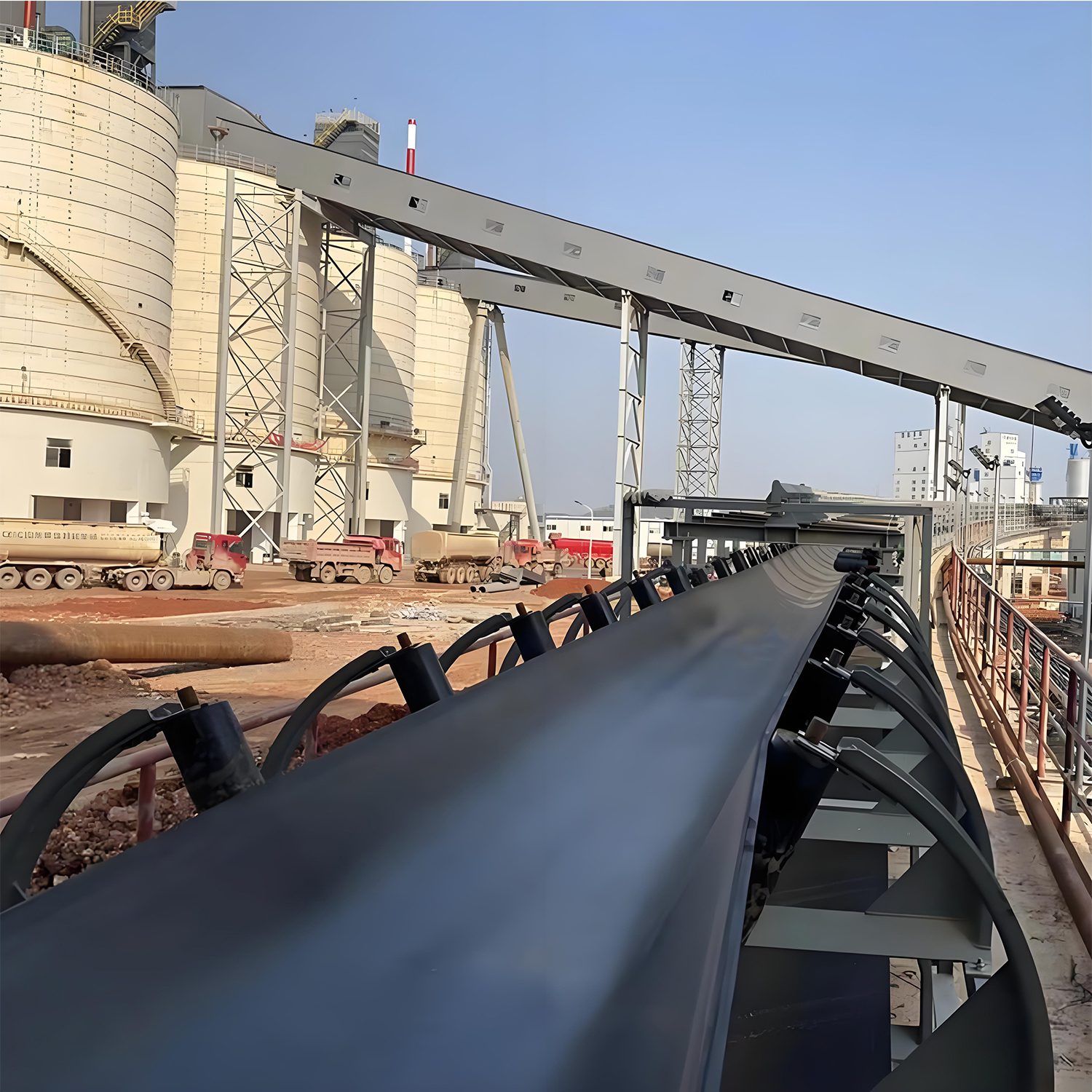

Что такое ленточный конвейер?

A belt conveyor is a mechanical device that transports materials continuously through friction-driven motion. It consists mainly of a frame, conveyor belt, rollers, drums, tensioning device, and drive unit. This system facilitates the flow of materials from an initial feeding point to a final discharge point along a defined conveyor line. It can transport both bulk materials and packaged items. Additionally, it can integrate with industrial processes to create a rhythmic assembly line.

The belt conveyor operates based on the principle of friction, making it suitable for transporting easily accessible bulk materials, granular substances, and small lumps, such as coal, gravel, sand, cement, fertilizers, and grains. The belt conveyor system functions within a temperature range of -20°C to +40°C, with the conveyed materials not exceeding 60°C. Users can determine the length and configuration based on their requirements, with the drive available as electric drums or drive units with belt drives.

Дарко, as a professional belt conveyor manufacturer, can guide you in selecting the appropriate model. We offer heavy duty conveyor belts and lightweight models. Our strength lies in customizing high-performance belt conveyors to meet the most demanding applications, providing products such as high-durability, wear-resistant, and high-temperature belts.

Working Principle of Belt Conveyors

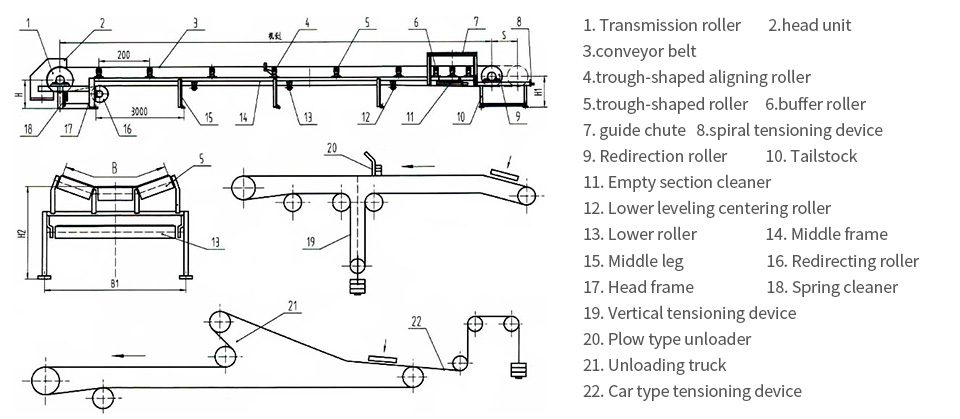

A belt conveyor consists of two end drums and a closed conveyor belt that wraps around them. The drum that drives the belt is called the drive drum, while the other drum changes the direction of the belt’s movement and is known as the redirecting drum. The drive drum is powered by an electric motor through a gearbox, and the belt moves due to the friction between the drum and the belt. Typically, the drive drum is located at the discharge end to increase traction, aiding in material movement. Materials enter from the feeding end and fall onto the rotating conveyor belt, which transports them to the discharge end.

Features of Belt Conveyors

Mining belt conveyors are ideal for high-efficiency continuous transport in coal mining. They offer benefits such as long conveying distances, high capacity, and reliable operation. They are easy to automate and centralize control, making them crucial for high-yield, efficient mines.

The main features include:

- Flexible Length: The body can easily extend or retract.

- Компактный дизайн: It can be installed directly on the floor without a foundation.

- Easy Assembly: The lightweight frame allows for convenient installation and disassembly.

- Intermediate Drive Options: For longer distances and higher capacities, intermediate drive units can be added.

Design Considerations

When designing a ленточный конвейер system, consider the following:

- Рабочая среда: Assess daily operation time, frequency, service life, and feeding/unloading methods. Consider environmental temperature, outdoor or indoor settings, and any mobility or expansion requirements.

- Conveying Route and Belt Issues: Evaluate the dimensions of the conveying route, including incline, maximum length, and lift height, along with straight and curved sections.

- Material Properties and Conveying Capacity: Examine specific material characteristics, such as bulk density, angle of repose, particle size, moisture content, wear resistance, adhesion, and friction coefficient. Determine the conveying capacity based on uniform and non-uniform material flow.

Types of Belt Conveyors

1. Standard Type

- Fixed Belt Conveyors: Suitable for horizontal or slight incline applications, commonly used in coal mines and preparation plants.

- Lightweight Fixed Belt Conveyors: Ideal for short-distance transport and light loads.

2. High-Strength Type

- Steel Cord Belt Conveyors: Designed for long-distance transport with high strength and low transportation costs.

3. Specialty Structure Type

- Telescopic Belt Conveyors: Adaptable for mining applications, allowing length adjustments based on work face changes.

- Horizontal Curved Belt Conveyors: Efficiently navigate around obstacles and reduce the need for intermediate transfer stations.

- Air Cushion Belt Conveyors: Utilize air cushions to reduce friction and enhance efficiency.

- Tube Belt Conveyors: Provide enclosed transport to minimize environmental pollution.

Types of Conveyor Rollers

1. Standard Rollers

These are the most common types, consisting of a large diameter shell and bearings. They reliably transfer materials.

2. Drive Rollers

Drive rollers, also known as electric or head rollers, are the core mechanism of the belt conveyor system. They provide necessary traction and often feature textured surfaces to enhance friction.

3. Specialty Rollers

- Reducing Rollers: Slow down material transport for smooth delivery.

- Buffer Rollers: Minimize belt slippage and improve efficiency.

- Redirecting Rollers: Change the belt’s direction to create a continuous loop.

- Tensioning Rollers: Maintain tension in the belt for optimal operation.

- Wing Rollers: Clean the return belt effectively.

- Magnetic Rollers: Separate ferrous and non-ferrous materials.

- Crowned Head Rollers: Ensure stable belt operation.

These rollers can be customized based on specific operational needs to meet unique material handling requirements. Whether for standard applications or specialized demands, our roller products deliver exceptional performance and reliability.

Transport Capacity Parameters

| Belt widthmm | Скорость ремня (м/с) | |||||||||

| 0.80 | 1.00 | 1.25 | 1.60 | 2.00 | 2.50 | 3.15 | 4.00 | 5.00 | 6.50 | |

| Производительность транспортировки (т/ч) | ||||||||||

| 500 | 69 | 87 | 108 | 139 | 174 | 217 | ||||

| 650 | 127 | 159 | 198 | 254 | 318 | 397 | ||||

| 800 | 198 | 248 | 310 | 397 | 496 | 620 | 781 | |||

| 1000 | 324 | 405 | 507 | 649 | 811 | 1014 | 1278 | 1622 | ||

| 1200 | 593 | 742 | 951 | 1188 | 1486 | 1872 | 2377 | 2971 | ||

| 1400 | 825 | 1032 | 1321 | 1652 | 2065 | 2602 | 3304 | 4130 | ||

| 1600 | 2188 | 2733 | 3440 | 4373 | 5466 | |||||

| 1800 | 2795 | 3494 | 4403 | 5591 | 6989 | 9083 | ||||

| 2000 | 3470 | 4338 | 5466 | 6941 | 8676 | 11277 | ||||

| 2200 | 6843 | 8690 | 10863 | 14120 | ||||||

| 2400 | 8289 | 10526 | 13158 | 17104 | ||||||

Чертеж ленточного конвейера

Scope of Application

Belt conveyors are versatile systems used extensively across various industries, including metallurgy, coal, transportation, hydropower, chemical, construction materials, power, light industry, grain, and ports. They can transport materials both horizontally and at inclines, making them suitable for diverse applications such as underground mine tunnels, surface transportation systems, open-pit mining sites, and mineral processing plants. Depending on the transportation requirements, operators can utilize a single unit or combine multiple units with other equipment, allowing for the creation of flexible horizontal or inclined transportation systems that adapt to different production line layouts.

Choose Darko for your Coal Conveyor Belt needs and elevate your material handling efficiency!