Pulse jet bag filters are essential in industries like cement plants. But blockages can slow you down. Don’t worry—here’s a simple guide to keep your system running smoothly.

1. Find the Cause of the Blockage

Check the Dust First

Dust isn’t all the same. Some types stick to bags more easily. If your dust is sticky or absorbs moisture, you’ll need extra care. Keep things dry and clean the bags often.

Is the Filtration Speed Too High?

A fast filtration speed means dust piles up quickly. Slow it down a little. This reduces buildup and helps your bags last longer.

Test the Cleaning System

If cleaning isn’t strong enough, dust stays on the bags. Check the system often. Adjust the cleaning time and pressure for better results.

Inspect the Bags

Old or damaged bags cause problems. Replace them before they fail. Also, make sure you’re using the right material for your dust type.

2. Clear the Blockage—Fast!

Clean More Often

Boost cleaning frequency or pressure. This keeps bags free of heavy dust layers.

Pre-Treat Problem Dust

For sticky or moist dust, add a pre-treatment step. Use a pre-dust collector or control air humidity. This stops dust from clogging the bags.

Upgrade Your Bags

Some bags work better than others. Try high-permeability or membrane filter bags if blockages keep happening.

Check the Whole System

Look at the hopper, valves, and ducts. Remove any trapped dust. A small blockage here can hurt performance.

Try Chemical Cleaning (If Needed)

For tough clogs, use a safe cleaning solution. Just make sure it won’t damage the bags.

3. Stop Blockages Before They Start

Stick to a Maintenance Schedule

Regular checks prevent big problems. Clean the hopper, inspect bags, and adjust settings as needed. Keep records to track what works.

Train Your Team

Good operators make a difference. Teach them the best ways to run and maintain the system.

Control Dust at the Source

Less dust means fewer clogs. Improve dust collection and handling early in the process.

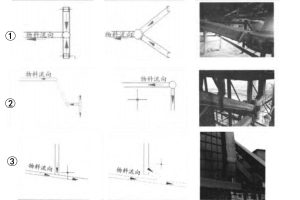

Bonus: Smart Setup for Cement Plants

Place your pulse jet bag filter away from fans and ducts. Add maintenance stairs for easy access. This small change saves time and trouble.

Final Tip

Blockages slow production, but they’re fixable. Follow these steps to keep your filter working perfectly. Need help? Contact us anytime—we’re happy to assist!