Importance of Dust Collection Systems

In nearly every industrial facility, Baghouse Dust Collectors play a crucial role in maintaining air quality. These systems significantly impact profitability by influencing downtime, energy costs, lost production, and potential fines. Therefore, selecting the right industrial dust collection system is essential for maintaining operational efficiency and adhering to environmental regulations.

Advantages of Gas Box Pulse-Jet Baghouse Dust Collectors

The gas box pulse-jet Baghouse Dust Collector stands out with a dust removal efficiency of over 99.99%, ensuring that dust emissions remain below 5 mg/Nm³. This system can effectively handle high-concentration dust levels of up to 100 g/Nm³. Its advanced sealing measures maintain a leakage coefficient of less than 2%, ensuring minimal loss and maximum effectiveness.

Moreover, the innovative design of this dust collector ensures compactness while enhancing performance. The unique dust cleaning method not only extends the lifespan of the filter bags but also optimizes operational efficiency. With stable performance, high automation, and straightforward maintenance, these Baghouse Dust Collectors become invaluable assets for industrial facilities.

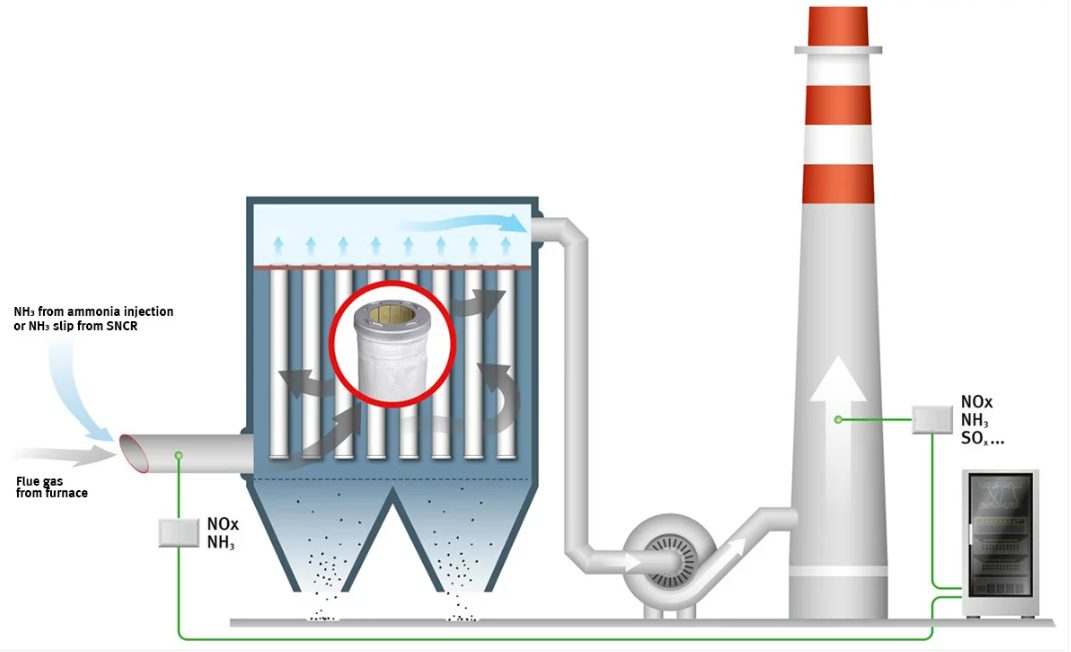

How does Bag Filter Dust Collector Working?

| Bag Filter Dust CollectorDust-laden air enters the cleaning trunk from the bottom of the Baghouse Dust Collector. Gravity causes coarse dust particles to fall into the dust cellar, while fine dust particles adhere to the surface of the filter bags. As dust accumulates, resistance increases, reducing the air volume processed. To maintain effective operation, the system periodically removes dust from the filter bags. During the cleaning process, a controller sends signals to each electromagnetic pulse valve. This action triggers the filter bags to contract and expand rapidly. The pulsating action effectively dislodges dust, ensuring stable pressure and air quantity throughout the system. |

Conclusion

In summary, Baghouse Dust Collectors are essential for maintaining clean air in industrial environments. Their high efficiency and innovative design not only improve air quality but also enhance operational productivity. By investing in a reliable dust collection system, facilities can safeguard both their workforce and the environment.